Digital cameras vie for multispectral applications

With a small number of CCD imagers to choose from, camera vendors are limited in the types of cameras that they can offer. Differentiated only by the types of CCD sensor, on-board processing capability, and digital interfaces, many of these cameras, at first glance, seem very similar. To distinguish their products, companies have chosen to develop devices for smaller, niche markets, such as high-speed or low-light level imaging. Although these products may not be commodity volume products, they do command premium prices, since they are used in relatively specialized applications.

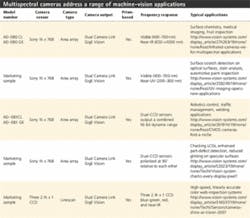

Recognizing this trend, JAI (Copenhagen, Denmark; www.jai.com) has identified another relatively untapped market for its latest range of C3 cameras—multispectral imaging (see table on p. 18). Multispectral imaging can be performed in a variety of ways depending on the object to be inspected. In its simplest incarnation, multispectral imaging can be done with a single camera and several different filter wheels that are mechanically moved in front of the camera before the image is exposed. Although this technique is the least expensive of all the multispectral methods, it suffers in real-time applications where images need to be captured at high speeds.

To address these applications, manufacturers, including JAI, have turned to prism-based approaches in the design of their cameras. One of the first companies to introduce prism-based cameras was Duncan Tech (Auburn, CA, USA; www.duncantech.com), whose cameras are now being offered by Geospatial Systems (West Henrietta, NY, USA; www.geospatialsystems.com). In the camera design, an optical prism separates different frequencies of light that are then detected by two or more CCD imagers that abut the prism. In the design of Geospatial Systems MS4100, for example, three 1-in. interline transfer CCDs with 1920 × 1080 pixels are used to individually image the red (550–700 nm), green (480–570 nm), and blue (400–530 nm) parts of the visible spectrum.

JAI has manufactured prism-based cameras for more than five years. These have been 3CCD models configured to produce true RGB color output. Rather than use such large CCD imagers, however, JAI has chosen to implement its prism-based camera series using less-expensive 1k × 768 1/3-in. CCDs from Sony (Tokyo, Japan; www.sony.com). However, it is not just the sensor that differentiates JAI’s products. It is also the manner in which JAI has positioned a new line of multi-CCD cameras to use different portions of the spectrum, both visible and invisible, to address multiple applications in machine-vision and image-processing applications.

For example, the company’s AD-080 CL multispectral camera, introduced at VISION 2007 in Stuttgart, Germany, uses two CCDs to detect frequencies in the visible and near-infrared portion of the spectrum. In its design, JAI uses an IR filter to separate the IR spectrum from the visible and outputs the resulting precisely registered data on two Camera Link Base channels. A GigE Vision version, the AD-080 GE, is scheduled for release in Q2 ’08.

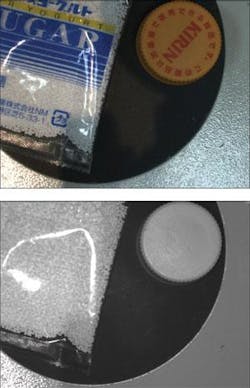

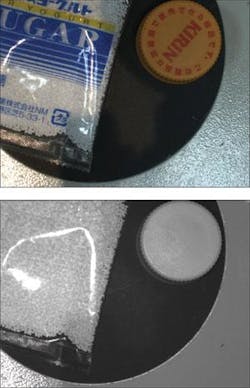

At a recent demonstration of the camera at the company’s San Jose, CA facility, Steve Kinney, director of technical pre-sales and support, showed how the camera could capture both visible and IR images at 30 frame/s (see figure). “By using a PC dual-core processor, system developers can partition their software to process both visible and IR images simultaneously,” Kinney says. Typical applications for the device are expected to be in surface chemistry, medical imaging, and fruit inspection, where the results from a visible analysis such as object size detection can be combined with stain, thermal, or fruit-bruise analysis using a single camera.

Of course, Kinney and his colleagues realized that this approach could be extended into other multispectral products. Indeed, the company was able to demonstrate a number of other cameras, including both defined products and marketing prototypes, using various combinations of wavelength sensitivity. These include multispectral prism-based area-array cameras that digitize both visible and IR, a camera that uses dual visible CCDs to extend the dynamic range of the camera to 16-bits, and a dual-CCD area-array camera that uses crossed polarizers on each individual output channel. Like the AD-080 CL, these cameras will each address a specific niche in the machine-vision market.

One of the most common applications for UV imaging, for example, is the detection of scratches on a surface. Since UV wavelengths tend to scatter more strongly than visible light from surface features, scratches not apparent in a visible image may be viewed in a UV image (see Vision Systems Design, July 2006, p. 25). For relative-contrast measurements, however, cameras that incorporate a high-dynamic range are especially useful in applications such as robotics control, welding, and traffic management (see Vision Systems Design, August 2006, p. 53).

Finally, when diffuse defects need to be detected against a shiny background, capturing two crossed polarized versions of the image is especially useful. In the past, integrators may have used a linear polarizer in front of an illuminator and a crossed linear polarizer in front of the camera lens to highlight diffuse defects. Now, since the crossed polarizers are incorporated into the camera no external polarizers are needed.

“This will prove especially beneficial in applications such as flat-panel LCD inspection,” says Kinney, “where external lighting results in glare from the display glass. Since LCDs polarize reflected light, the polarizing filter within the camera can be aligned to transmit only that polarity of light making any pixel defects immediately apparent” (see Vision Systems Design, May 1999, p. 9).

To complete its latest multispectral product offerings, JAI will also offer a linescan camera that uses three 19-kHz linescan CCD imagers filtered as blue-green, red, and near-IR. Once again, the design of the camera uses a prism to precisely register the linescan images as they are captured by the camera.

“Other multispectral linescan cameras use multiple individual or monolithic CCDs to capture these images. However, because they must physically be separated, image artifacts may occur when the sensor is used in high-speed applications. Prism-based multispectral cameras do not exhibit these effects since the CCDs can be perfectly registered.”

Perhaps the most important part of JAI’s recent announcement, however, is not the technology itself. Rather, by abandoning the “me-too” approach taken by many camera vendors, JAI has recognized the need to distinguish its products from its competitors, while offering added functionality within a single camera.