Smart camera system simplifies 3-D profiling

Karlsruhe, Germany

www.evt-web.com-- Posted by Carrie Meadows, Vision Systems DesignFind information on Smart Cameras

------

PRESS RELEASE

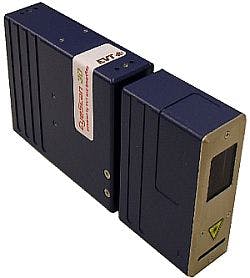

EyeScan 3D - three dimensional vision in the solar industry

The new smart camera systems EyeScan 3D of EVT makes the third dimension accessible to the user. The cabinet measures only 195 x 90 x 35 mm and contains an already calibrated laser triangulation sensor as well as an evaluation processor. The evaluation processor can thread in up to 40000 3D-profiles per second. The complete evaluation software is contained in the system and can be programmed by drag-and-drop. All topics can be realized, from simple testing method tasks to object recognition with robots. The multiplicity of algorithms allows to solve even complex three-dimensional problems with the same simplicity like two-dimensional tasks. Now the system possesses the Solar Plug-in which has been especially developed for the solar industry in order to realize more well-priced three-dimensional solutions in the future. Even specific tasks in the production of solar cells, solar strings and modules can be realized efficiently with the SolarEye plug-in.

The inspection system detects material failure in the ongoing production process. Therefore the rate of yield of the production increases. In the field of solar different applications can be solved simply with a series of specialized commands. The exact detection of micro cracks and other wafer defects is important for the wafer protection as well as for the production of solar cells in order to avoid wafer breakage. That way the production runs failure-free.

The evaluation unit and the sensor are not only integrated into the cabinet of the EyeScan 3D system they are also pre-calibrated. The pre-calibration makes sure that the user only has to look after the installation of the sensor. There is no expert necessary who integrates and calibrates the system. The user has also the possibility to replace an existing sensor by a new one at any time without calibrating the system again. It will do to replace the old sensor by a new one and to input the testing program in the new sensor.

The solar plug-in SolarEye countervails the defects of fabrication like scratches and brink disruptions on wafers. The high-resolution cameras discover any faults at an early stage. The test system solves essential inspection tasks: the system detects edge disruptions, checks for correct measurements and controls the accuracy of the size and the surface. In addition the position as well as the rotation of the cell can be determined in order to solder cells. The solar plug-in has been extended to a solar module for laser scribing inspection. Naturally also general inspection tasks like reading DMC, OCR/OCV and bar codes have been adjusted for the solar industry. That means it is possible to read DMC, OCR/OCV and bar code even on silicon and solar cells.

Based on the high-resolution cameras any failures can be detected accurate to a µm. Once the failure is detected the defective wafers can be locked out of the production. Consequently the breakage rate in the production can be reduced considerably and the rate of yield increases directly. The information about the defect characteristics of the solar wafer are collected by the evaluation software during the ongoing production. That permits a continuous and systematic improvement of the production process. The system offers you a maximum of accuracy and nethermost costs at the same time.

The novelty of this system is that everything is integrated completely and therefore the three-dimensional evaluation can be programmed as simple as a normal image processing system. The system can be connected to directly to a monitor in order to control the ongoing production and the measuring results. The results and the image data can be transferred via interfaces like for example Gigabyte Ethernet, RS232 or RS485. Therewith the three-dimensional sensor can be integrated into the existing business software and additionally the connection to the robot can be realized.

The results of measurement can be also transferred to the business software of SAP and ORACLE via optional software interfaces. Consequently the test results are available in the company anywhere and at any time.