Automating Assemblies

Combining off-the-shelf cameras, lighting, and software with a Cartesian robot allows microelectrode assemblies to be rapidly inspected

Andrew Wilson, Editor

Cellular dielectric spectroscopy (CDS) is an impedance-based measurement technique that measures the changes in electrical impedance relative to a voltage applied to a layer of cells in which no cell is growing on top of another. Eliminating the need for tags, dyes, or specialized reagents, the technique relies on the fact that specific cell receptors or glycoproteins of the cell’s plasma membrane have binding sites for specific adhesion molecules.

By activating these receptors using antibodies or artificial reagents, morphological cellular changes occur that affect the changes in current flow across the cell. Measuring the changes in impedance of a voltage applied across the cells can then be used to indicate the level of binding at specific receptors, a particularly useful measurement for drug development.

To perform these measurements, companies such as MDS Analytical Technologies, now part of Danaher Corp., build systems that automatically apply different reagents to cells and measure their impedance using the CDS technique. The company’s CellKey 384 system, for example, is designed for cell-based kinetic screening of 384-well microtiter plates processing up to 24,600 wells in eight hours.

“To properly measure the impedance in each of the microtiter wells,” says Uwe Trautenbach, manufacturing engineering manager at Conductive Technologies, “the conductance at each well must be measured.” As a third-tier supplier to the pharmaceutical industry, Conductive Technologies manufactures these 384-well microtiter plates equipped with electrochemical sensors specifically for these tasks.

Bottomless wells

A bottomless 384-well plate manufactured of polycarbonate must be bonded to an array of 384 electrodes that are in turn accessed by an array of contact pads (see Fig. 1). In the development of the electrode array, polyethylene terephthalate (PET) cards coated with gold film are first laser ablated to form the array of electrodes.

Once the electrodes are formed, contact pads for each of the electrodes are screen-printed onto the film along with spacing material. Before this finished array of sensors and contact pads can be bonded onto the polycarbonate plate, however, each individual electrode must be inspected to ensure that it will function properly.

“During various post-processing techniques of the electrode assembly there is a large probability of damaging the vacuum vapor-deposited gold layer on the PET film,” says Trautenbach. “Cards with defects need to be rejected as false acceptances cannot be tolerated; this makes the final test plate defective.”

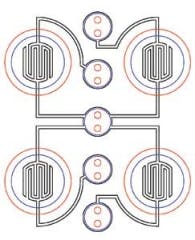

Because of this, each of the two individual electrodes spaced 100 µm apart used at each of the 384 well sites must be inspected. If, for example, the electrodes are fused together, a proper impedance measurement will be impossible. Alternatively, if the electrodes are spaced too far apart or too close together, an incorrect impedance measurement will be made.

In the past, the inspection of these electrode fingers was accomplished manually by operators using microscopes. “However, even for experienced technicians this was an extremely strenuous task and one prone to human error,” says Trautenbach.

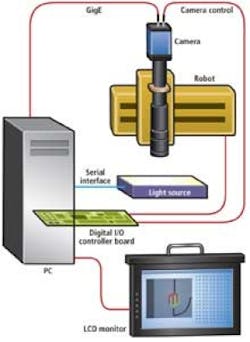

Realizing this, Trautenbach and his colleagues have designed and developed a semiautomated system capable of accomplishing the inspection of the microtiter electrode cards at a rate of 10 plates per hour (see Fig. 2). In the design of the system, Conductive Technologies’ PC-based system used off-the-shelf lenses, lighting, I/O cards, and machine-vision software integrated with a commercially available Cartesian robot.

After a finished product is successfully tested, it is shipped to companies such as Danaher whose CellKey system then fills the microtiter plates and makes measurements using the bonded contact pads on the finished electromechanical plate.

Imaging electrodes

To properly image the 5 × 3.5-in. electrode cards, they are first placed in a fixture that is located on the surface of a 5 × 5-in. white fiberoptic backlight from Volpi. Driven by an IntraLED 2020 white LED light source, also from Volpi, this backlight provides a homogenous 5.6-Mlux illumination of the electrode card surface and is controlled from the serial port of the host PC.

After the electrode card is placed in position, all 384 electrodes must be imaged. To roughly locate the electrodes’ position in the field of view, a PicSight 202N CCD GigE Vision camera from Leutron Vision is mounted onto the horizontal axis of an x-y-z Cartesian robot from Fisnar.

“Coupling the 1624 × 1236[-pixel] CCD camera with a 90-mm VZM 450i lens from Edmund Optics allows the camera to image the 100-µm spacing between the electrodes to a repeatable accuracy of ±5%,” says Trautenbach (see Fig. 3).

By using Robot Edit software running on Windows XP Pro, the path of the robot and camera focusing are programmed to locate the approximate position of each electrode. After the robot travels to a specific location, the camera system is triggered to image the electrode site using an 8012 low-profile PCI digital interface card from Sealevel Systems. This provides eight Reed relay outputs (SPST) and eight optically isolated inputs that are used to drive the robot and trigger the camera system.

After images of the electrodes are captured by the camera, they are transferred over the GigE Vision interface to host PC memory and displayed on an LCD monitor (see Fig. 4). “To analyze the shape of the electrodes within the image, the captured image is first compared with a known good master image that is stored as a bitmap file in the host PC,” explains Trautenbach. This is performed using the Halcon image-processing and machine-vision software package from MVTec Software.

FIGURE 4. After images of the electrodes are captured by the camera, they are transferred to host PC memory and displayed on an LCD monitor. To analyze the shape of the electrodes, the image is first compared with a known good master image; an ROI is isolated; the gold electrodes are highlighted; and shape and distance measurements of the electrodes are performed.

Regions of interest

“After the images are compared, a known good region of interest (ROI) can be isolated within the captured image to locate the electrode pair,” says Trautenbach. Once the ROI is located, it is then thresholded to highlight the gold electrodes from the PET film background of the electrode card. Once extracted, the morphology of the electrodes can be examined.

“Within the ROI there should be only two electrodes,” notes Trautenbach. “Thus, counting the number of connected pixel areas within the ROI should return a value of just two connected regions. If, for example, the system returns a value of one, then the electrodes may be fused and may be rejected. If the system returns a result of more than two, the electrodes may be damaged.”

After determining the presence of a single pair of electrodes, area measurements of the electrodes are performed, again using Halcon to determine correct impedance measurements will be made. “By measuring this electrode area within specific predetermined values, pass/fail criteria can be established. This is also used to determine whether a pass/fail decision should be logged or flagged to the operator.

“Although programming the vision system only took a few days inside the Halcon 8.0 vision application development environment,” says Trautenbach, “most of the programming development was spent on the Visual Basic (VB) 6.0-based user interface, logic, and robotics handling.”

After the vision algorithms were completed, they were then exported with a built-in Halcon software tool and embedded in the Visual Basic software development kit (SDK). Besides image acquisition and processing, VB also supports the host user interface and logic for the I/O and CNC robot.

After each individual electrode card is tested, the results are displayed on the LCD monitor. From this screen the operator can recall and view any electrode pair images that are flagged as possible failures and perform a final pass/fail decision on the part. Alternatively, as the system inspects each individual electrode pair, the operator can program the system to stop and display any potential faults as they are being inspected. “In this way,” says Trautenbach, “the operator can determine any faults and reject a part before the entire electrode array is analyzed.”

Costing approximately $65,000, Conductive Technologies has developed the system primarily for its own internal testing of microtiter electrode arrays.

Company Info

Conductive Technologies

York, PA, USA

www.conductivetech.com

Edmund Optics

Barrington, NJ, USA

www.edmundoptics.com

Fisnar, Wayne, NJ, USA

www.fisnar.com

Leutron Vision

Glattbrugg, Switzerland

www.leutron.com

MDS Analytical Technologies (part of Danaher)

Washington, DC, USA

www.danaher.com

MVTec Software

Munich, Germany

www.mvtec.com

Sealevel Systems, Liberty, SC, USA

www.sealevel.com

Volpi, Auburn, NY, USA

www.volpiusa.com