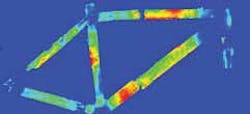

Thermal imaging detects material failure in carbon-based bicycle frames

To identify hidden stress defects in carbon-based bike frames, Carl Messtechnik (Dinsladen, Germany) has employed a pulse thermographic method to trigger a thermal pulse through the material and then used a SC7000thermal imaging camera from FLIR Advanced Thermal Solutions (Croissy-Beaubourg, France) to trace the heat flow. Differences in the heat flow data collected by the FLIR SC7000 provided a insight into stress-induced flaws in the carbon-fiber reinforced materials.

Modern bike frames, especially those at the higher priced end of the market, are made from carbon-fiber reinforced plastics, which are exceptionally light and strong. The way these frames behave in the case of damage and failure is fundamentally different from traditional metal frame bikes. Instead of bending, carbon-fiber reinforced materials simply break. This potentially exposes riders to failures that may lead to injury or death.

Volker Carl, Managing Director of Carl Messtechnik, commented, "The cooled Indium Antimonide (InSb) detector used by the FLIR SC7000 thermal imaging camera is extremely sensitive (<20 mk) and provides high contrast thermal images at a resolution of 640x512 pixels."

SOURCE:FLIR Advanced Thermal Solutions

--Posted byVision Systems Design