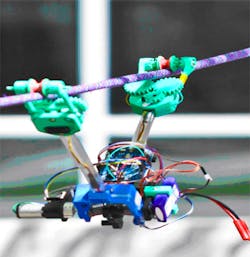

Robot inspects power lines

Mechanical engineers at the University of California, San Diego (La Jolla, CA, USA) have invented a robot designed to run along utility lines, searching for damage and other problems that require repairs.

Made of off-the-shelf electronics and plastic parts printed on an inexpensive 3-D printer, the so-called SkySweeper prototype could be scaled up for less than $1,000, making it significantly more economical than the models of robots currently used to inspect power lines.

"Current line inspection robots are large, complex, and expensive. Utility companies may also use manned or unmanned helicopters equipped with infrared imaging to inspect lines," said Nick Morozovsky, a graduate student in mechanical engineering. "This is much simpler."

Morozovsky designed the robot in the Coordinated Robotics Lab led by mechanical and aerospace engineering professor Tom Bewley.

SkySweeper could be outfitted with induction coils that would harvest energy from the power line itself, making it possible for the robot to stay deployed for weeks or months at a time. SkySweeper is V-shaped with a motor-driven "elbow" in the middle and its ends are equipped with clamps that open and close as necessary to move it down the line, inch by inch.

Morozovsky is strengthening the clamps so they can release from the rope and swing down the line, one end to the other, thereby swinging past cable support points.

A video of the robot in action is available on YouTube here.

Related items from Vision Systems Design that you might also find of interest.

1. Vision-guided robot patches up wood

Researchers led by wood-inspection system developer Microtec are involved in a €4 million European 7th Framework project to develop a totally automated robotic system for repairing defects in laminated wooden panels.

2. Vision guided robot enters risky areas

Engineers at Toshiba Corporation (Tokyo, Japan) have developed a tetrapod robot that is able to carry out investigative and recovery work in locations that are too risky for people to enter, such as Tokyo Electric Power Plant Fukushima No.1 nuclear power plant.

3. 3-D vision optimizes robotic car parking

Serva transport systems and in-situ Vision & Sensor Systems have developed a fully automated car parking system that makes use of more of the space in a parking garage by first identifying a vehicle and then transporting it to an empty parking slot using a self-guided robot trolley.

-- Dave Wilson, Senior Editor, Vision Systems Design