Page 2: Machine vision system identifies defects in uniform web materials

Images captured by the Piranha cameras are processed using Matrox Imaging Library image processing, blob analysis, and calibration modules. Processing operations used include convolution, binarization, morphology (dilate and erode), flat-field correction and projection. AI Surface inspects a web that is 130 inches wide at a rate of 670 feet/minute. The inspection system can detect defects as small as 0.008 inch by 0.008 inch.

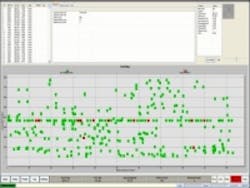

The system, which features an intuitive touchscreen HMI that provides real-time feedback and tuning, supports alarms, flagging, machine control, and waste removal actions. When a serious class of defect occurs, the operator sees the defect on the screen and a designated action sequence is activated, as such as driving a downstream device to reject.

Knowlton Technologies, a global designer and manufacturer of wet-laid non-wovens in filtration, friction, and custom designed composite webs, recently had an AI Surface inspection system installed.

"AI Surface let us remove three workers from a 100% manual inspection procedure and place them in higher value-added positions as soon as the system was installed, which allowed us to realize a quick return on our investment," said Richard F. Barlow, Advanced Materials Engineer, Knowlton Technologies. "Also, the user interface is set up so that is simple to create multiple custom classifiers for various customer needs and link to their specific grades."

Looking ahead, Active Inspection is planning the development of an inspection system that utilizes CMOS cameras that support higher speeds, as well as developing a system that supports up to 16 cameras.

View more information on Matrox Imaging Library.

View more information on Teledyne DALSA Piranha2 cameras.

View more information on Teledyne DALSA Piranha3 cameras.

Also check out:

Industrial Inspection: Line-scan-based vision system tackles color print inspection

Modular vision system eases printed circuit board traceability

Putting instrument panels through their paces

Share your vision-related news by contacting James Carroll, Senior Web Editor, Vision Systems Design

To receive news like this in your inbox, click here.

Join our LinkedIn group | Like us on Facebook | Follow us on Twitter | Check us out on Google +

Page 1 | Page 2

About the Author

James Carroll

Former VSD Editor James Carroll joined the team 2013. Carroll covered machine vision and imaging from numerous angles, including application stories, industry news, market updates, and new products. In addition to writing and editing articles, Carroll managed the Innovators Awards program and webcasts.