A University of Arizona-led team of researchers have developed an inexpensive, lightweight infrared lens made from sulfur left over from oil and gas natural refining.

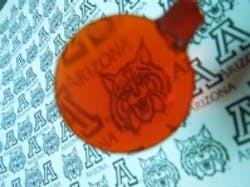

The researchers, who published a paper on the study, were able to turn sulfur left over from refining fossil fuels into a plastic polymer lens that was successfully tested and used to capture infrared images that showed a person’s body heat.

"We have for the first time a polymer material that can be used for quality thermal imaging – and that's a big deal," said senior co-author Jeffrey Pyun, whose lab at the UA developed the plastic. "The industry has wanted this for decades."

This development is potentially significant because the materials used are less expensive than materials currently used in infrared technology, and can also be easily molded into a variety of shapes, suggested Pyun. In addition, the discovery would also provide a new use for sulfur left over from when oil and natural gas are refined into cleaner-burning fuels.

In tests, the lenses were found to be transparent to the mid-wave infrared range (3 µm x 5 µm) and have a refractive index between 1.865 and 1.745. Most other polymers have refractive indices below 1.6 and transmit much less light in the mid-range infrared, according to the authors of the paper.

Dubbed "inverse vulcanization" by the researchers, the process in which the lenses were made was discovered when team members were trying to transform liquid sulfur into a useful plastic that could be produced easily on an industrial scale. To make the lenses, a liquid concoction was poured into a silicone mold similar to those used for baking cupcakes.

"You can pop the lenses out of the mold once it's cooled," said co-author Jared J. Griebel. "Making lenses with this process – its two materials and heat. Processing couldn't be simpler, really."

Potential uses for the newly developed lenses include home energy audits, night vision, surveillance systems, and remote sensing applications, suggested senior co-author Robert A Norwood, a UA professor of optical sciences. In addition, the researchers have filed an international patent for the chemical process and its application for lenses, and several companies have already expressed interested, according to Pyun.

Next steps involve the comparison of the properties of the new plastic with existing plastics, and exploring other practical applications, such as optical fibers.

This news isn’t the only recent news involving research with new types of image sensors. Back in March, the University of Michigan released a press release indicating that engineering researchers have developed a detector made of graphene that is able to detect the full infrared spectrum. Read more about that news here.

View the UA press release.

Also check out:

FAA approves flight of first commercial UAV

Infrared detector market predicted to hit $704.8 million by 2020

Vehicle attempting to break world land speed record has vision system put to the test

Share your vision-related news by contacting James Carroll, Senior Web Editor, Vision Systems Design

To receive news like this in your inbox, click here.

Join our LinkedIn group | Like us on Facebook | Follow us on Twitter | Check us out on Google +

About the Author

James Carroll

Former VSD Editor James Carroll joined the team 2013. Carroll covered machine vision and imaging from numerous angles, including application stories, industry news, market updates, and new products. In addition to writing and editing articles, Carroll managed the Innovators Awards program and webcasts.