Networked cameras check components

Smart cameras and DeviceNet architecture automate connector and fittings production.

By C. G. Masi, Contributing Editor

Colder Products, a manufacturer of advanced controlled-performance connections and fittings for industrial, medical, chemical-handling, packaging, and food-dispensing applications, asked Demco Automation to design an updated, highly automated production line to assemble male sides of its quick-disconnect fittings. The ability to quickly and easily reconfigure the process by swapping stations in and out of the line was a high priority, so Demco’s solution took a modular approach that machine-vision designers will find familiar.

Machine-vision designers have long embraced the idea of system adaptability through modularity. To create, say, an inspection system, they typically specify a set of commercial, off-the-shelf components, such as lenses, cameras, and light fixtures, interconnect them using standard industrial interfaces, such as TTL digital I/O or Ethernet, and control them using software assembled from standard high-performance utilities to perform such tasks as thresholding and blob analysis. This mix-and-match approach makes it easy to modify the vision system to do different tasks or to upgrade it with new technology.

Rigid automation systems that use a hierarchical architecture where a host processor coordinates subordinate subsystems through a master program work very well in static, high-volume/low-mix processes. When a manufacturing facility like Colder’s has to deal with a high-mix environment, where changeovers from one product to another are frequent, the time required to reconfigure the production line can reduce overall throughput, as well as raise costs.

Demco Approach

“Our focus is to provide scalable, modular, flexible automation solutions for our customers,” says Stephen Maund, director of engineering and manufacturing at Demco. “True plug-and-play technology and modularity is the key. We’re really providing a custom automation solution, yet it’s modular and flexible to accommodate, for example, changes in product scheme, design, or process. The user can very easily change it to meet those requirements.”

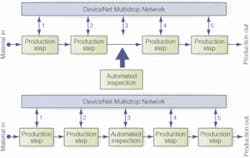

What differentiates Demco’s approach is that it uses a distributed control architecture rather than relying upon a single processor. Stations run independently, reporting back to a master controller, thus enabling modularity and adaptability in a custom system. This method increases flexibility compared to using one controller for the entire system (see Fig. 1).

Demco used DeviceNet to integrate the component stations making up Colder’s production system (see “DeviceNet Architecture,” p. 32). DeviceNet is a multidrop factory-automation standard that allows multiple drops from a backbone through so-called T-tap connections. Each drop can carry multiple factory-automation nodes either daisy-chained together or branching from the T-tap.

Not all drops have to be populated. Process engineers can leave zero-drops within the line to accommodate future expansion or as the result of process modifications. Consider a DeviceNet network with five drops, numbered 1 through 5. Suppose further that drop 3 is a zero-drop, meaning there is nothing connected to it but a termination to maintain the system’s electrical impedance. Perhaps there is a conveyor line running from the process station at drop 3 to the one at drop 5. In that case, the process engineer could add an automated inspection station suspended from a gantry over the conveyor to inspect the product as it passes from station 3 to station 5. At that point, all that is needed is to bolt the inspection system in place and plug it into the T-tap at drop 4. “You are able to connect it in a matter of minutes,” Maund reports. “It’ll take, when all’s said and done, a half-hour to put in this station and have it ready for production.”

In an automated inspection station that is part of the Colder process case, a robotic handler picks the part to be inspected from a “dial nest” on a rotating table called a “dial” and presents it to the camera by simply holding it in the field of view (see photo on p. 27). The inspection station quickly decides whether to accept or reject the part. If the part passes, the handler deposits the completed component into the good bin. If it doesn’t, the robot drops it into a reject bin on its way back to the dial to pick up the next part.

This modular, distributed-control architecture makes it possible to upgrade the process with practically no disruption. New stations can be built and tested off-line, then quickly plugged into the production system (see Fig. 2). The heart of one automated inspection station under development is a DVT Legend 510 image sensor, that includes sensor and image-processing functions. Once programmed via an Ethernet connection, the unit can capture the required image(s), perform all the image-enhancement functions needed to bring out the features of interest, make any measurements needed, and arrive at a conclusion that has significance to the process. Any triggers required to help the camera coordinate its activity with the rest of the system, as well as signals to disseminate high-level decisions (such as accept/reject), pass in and out via a digital I/O port.

In this case, the process engineers at Colder want to know whether an O-ring seal was placed correctly over the part’s fluid port. The port is a nipple that sticks out of the part’s body (see Fig. 3). An O-ring fits over the nipple to ensure a good fluid-tight seal. These fittings can be used with either gases or liquids. The production line includes automated pick-and-place stations to assemble the internal components, an ultrasonic-welding station to seal the fitting, and another pick-and-place to fit the O-ring into its groove around the nipple. The latter station also incorporates a machine-vision inspection system that performs two tasks: it verifies the proper placement of the external O-ring, and it verifies correct assembly of the internal components. It can perform both of these tasks with one image.

Inspection Station

The imaging system consists of the Legend 510 camera with a Tamron 16-mm fixed-focus lens with a 25-mm aperture and a 10-mm spacer to allow macro imaging. Illumination comes from an LED ringlight built into the camera surrounding the lens mount. In this case, the lens spacer allows such a short working distance to the part under inspection (PUI) that the shadow of the lens falls on the part. Light from the LED ring reflects diffusively from a white-plastic sheet mounted behind the part. The camera sees essentially no direct illumination on the PUI, but a backlit silhouette.

The smart camera makes two basic measurements. First, it checks the silhouette to make sure that the O-ring is there and that its distal face extends the right distance beyond the body. If that distance is wrong, it indicates that the part carries either the wrong size O-ring or more than one O-ring.

The second measurement is the distance that the nipple protrudes beyond the body. If this measurement is incorrect, it indicates an internal assembly error. For example, leaving out an internal O-ring would allow the nipple to protrude too far.

Each station has its own programmable logic controller (PLC) in the form of a MicroLogix 1200 Control System manufactured by Allen-Bradley. The PLC enters the DeviceNet as a drop from one of the net’s T-taps. The stations are then daisy chained along the branch.

“There is a branch down to a DeviceNet input module, which is where we plug in our station sensors,” explains Andrew Granan, the Demco Controls engineer who designed the system. “The sensors tell the system what stations are present.”

Demco’s design can have up to 16 stations around a standard dial. The modular architecture, distributed control, and automatic configuration features make it easy to reorganize the line by simply moving stations in and out. Fitting bolts hold the stations in proper alignment and connecting plugs make electrical contacts.

“The vision system made it possible for us to automate placing the external O-ring,” says John Holmblad, manager of manufacturing technologies at Colder Products. “Without it, we would have no way to automatically verify proper assembly. It has improved our product quality, production throughput, and manufacturing capacity. We plan to implement vision systems on all new systems and to integrate vision into existing processes whenever possible.”

DeviceNet Architecture

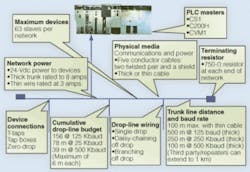

DeviceNet is an open factory-automation network managed by the Open DeviceNet Vendors Association (ODVA), which guarantees that the specifications remain open and tests products made by member companies for compliance. ODVA’s conformance testing policies ensure that DeviceNet products from different vendors are interoperable.

The DeviceNet standard provides a highly adaptable network. Starting from a multidrop backbone, the network can grow by extending the backbone with additional drops, branching from the branches, and daisy chaining to extend the branches.

Factory-automation integrators can use DeviceNet to interconnect a variety of system components, from simple on/off devices (such as interlocks and limit switches) to complex products such as vision systems. The standard offers robust, efficient data handling because it is based on a communications model that offers key capabilities that, in turn, allow the user to effectively determine what information is needed and when. - C. M.

Company Info

Allen-Bradley,

Milwaukee, WI, USA

www.ab.com

Colder Products,

St. Paul, MN, USA

www.colder.com

Demco Automation,

Quakertown, PA, USA

www.demcoautomation.com

DVT,

Duluth, GA, USA

www.dvtsensors.com

Open DeviceNet Vendors Association,

Ann Arbor, MI, USA

www.odva.com