LED lighting continues inroads in illumination

Advances in semiconductor and packaging techniques give LEDs advantages in many traditional and novel applications.

By J. Marcel LaFlamme

Most companies that provide illumination products to the machine-vision industry believe that many future improvements will emerge from developments in LED technology. During the last 10 years, LED-based products have gained more than 50% share of the machine-vision lighting market, and the market for such high-brightness LEDs is expected to increase to $8.2 billion by 2009, with the fastest-growing applications in general and special illumination.

Initially, the goal of LED-based lighting designers was to combine the electroluminescence properties of a semiconductor material (InGaN for the blue, green, andwhite LEDs and AlInGaP for red, orange, and amber LEDs) with nonimaging optics to produce an intense spot of light. However, the low intensity levels of LEDs limited their use to highly reflective applications. Today, die manufacturers are increasing the amount of energy that the die can absorb and emit, as new, lightweight ceramic and metallic substrates manage the heat generated at the p-n junction.

Both single-chip and multi-chip units qualify as high-brightness LEDs. The latest white LED XLamp 7090 from Cree, for example, produces luminous flux of up to 95 lm or 85 lm/W at 350 mA and up to 160 lm at 700 mA. Multichip units claiming more than 330 lm using nine 1-W LEDs in a 1.3-in. package are available from Optek Technology. In comparison, a 60-W incandescent bulb produces 840 lm. Such developments will greatly impact the machine-vision illumination market, making previously difficult application areas such as web inspections and traffic monitoring more reliable.

Using reflective and nonimaging optics, this light can be directed in a number of different ways. Today’s LED lighting products are available in several different forms, including semiconductor die, discrete LEDs, LED engines or arrays consisting of multiple dies, and LED systems that may include driver and power supplies. Lamina Ceramics Titan 3050K, for example, is a 25-W warm white LED light engine available in RGB and “daylight” white models. Emitting 1400 lm at 4700 K, the unit is roughly 2 sq in. in diameter (see Fig. 1).

Chip on board

LEDs have distinct advantages over other sources of light for machine-vision applications. These include long life, monochromatic wavelength from IR to UV, low power consumption, immunity to vibration and shock, instantaneous switching, and fast strobing capability. Modern chip-on-board (COB) designs offer the capability for LED illumination systems to be custom designed to meet the needs of a particular application.

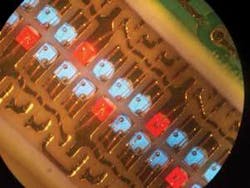

COB products are composed of a substrate, usually metal or ceramic, a reflecting cavity, a die or chip, and a custom optical overlay. To manufacture these, pick-and-place and die bonding machines are used. First, the die is picked from the wafer and placed directly on a substrate, where it is bonded and encapsulated with epoxy (see Fig. 2). Because the process controls the direct placement of the die, many dies can be placed in a very small cavity within the same footprint as a discrete LED. But the size, weight, and volume of the final product will be less than a similar product that uses discrete LEDs

StockerYale’s Cobra line light uses COB technology to maximize the number of dies that can be placed on the line configuration and allows the line light to compete with more-established fiberoptic line lights. Since linescan applications represent almost 40% of the market and have been mainly developed using fiberoptic components, COB technology is likely to increase the market share for LED illumination in these applications.

UV applications

Most LEDs are monochromatic and meet specific wavelength criteria such as those in the 375-nm UV range. Since UV LEDs are manufactured with InGaN technology, they dissipate a large amount of heat that can affect their usable lifetime. However, because they are solid-state devices, they are more practical than other fluorescent UV sources of illumination.

Ultraviolet illumination excites the fluorescent properties inherent in the material of a target. When this occurs the material reflects energy at specific wavelengths. This property of the material may be an accidental feature or it may be an intentional feature such as a fluorescent ink. In either case, the UV energy excites the florescent properties and leaves all other components dark, providing a high-contrast image.

Pharmaceutical and cosmetic manufacturers have been using fluorescent inks to mark the date and lot codes on their product containers for esthetic reasons, because the codes are not usually visible to the naked eye with natural light. However, this renders reading of the codes all but impossible, except with ultraviolet light. Ultraviolet LEDs also provide high-contrast images when inspecting sealing compounds or grease on fittings, since these usually contain fluorescent properties (see Fig. 3).

Halogen replacements

Combining substrate, die, and optics, Edmund Optics has developed an illuminator for fiberoptic bundles. In preliminary testing, the new LED technology provided a full match in intensity to the standard halogen bulb when measured at the end of the fiber. However, the lifetime of the LED unit is expected to be 50,000 hours compared to only 200-300 hours of an equivalent halogen bulb at full power. When testing was performed with the halogen at 80% of power to extend life to 2000 h, the LED unit was measured at 3.5 times the intensity and 50,000 hours of life.

Rather than use various doping techniques to produce white light, Edmund opted for RGB mixing technology, using multiple dies at full power, without superimposing other coatings, which absorb energy. Using nonimaging optics similar to a “light pipe,” the energy from the sources was combined to produce a bright and uniform pattern in the near and far field.

J. Marcel LaFlamme is a consultant in the field of machine-vision illumination and can be reached at [email protected].

LEDs challenge halogen in traffic monitoring

One of the fastest-growing applications of LED lighting is vehicle traffic monitoring. At Nestor Traffic Systems (Providence, RI, USA; www.nestor.com), a mobile speed-enforcement system and a red light enforcement system have been developed to track moving vehicles and measure their speed.

If a vehicle exceeds the speed limit, images of both the front and rear license plates are taken. To illuminate the plates, the system uses an 8 × 8-in. array of discrete IR LEDs. The monochromatic property of the LEDs and their instantaneous switching are key to this application, since the 830-nm wavelength flash does not blind the vehicle’s driver. Infrared illumination also reduces the influence of different color license plates and provides for a better gray-scale image.

In the red light enforcement system, a combination of nontactile sensors, cameras, lighting, and image-processing software identifies the speed of a vehicle as it approaches a stop light. The system predicts if the vehicle can stop or will speed through the intersection. If it is determined that the vehicle cannot or will not stop, an image of the front and rear plates is taken. In some cases an image will also be taken of the driver through the glass windshield.

At its inception, this project relied on the types of large halogen sources used in stage lighting. This lighting technology is both cumbersome and difficult to strobe.

Since the illuminator could be as much as 60 ft from the target, Nestor engineers began testing Siemens Nerlite products because they provide fast switching, a smaller footprint, lower energy consumption, and light-shaping capability. However, several engineering changes were required to meet the intensity needed for the application. This included the substitution of brighter LEDs as they became available. Although the intensity from the LEDs has not matched that of halogens, they are sufficiently bright to meet laboratory tests. Further tests will be performed in the field.