GigE camera seeks scallops

The fishing industry is Alaska’s largest employer and one of the State’s main economic resources. The Alaska Department of Fish and Game (ADF&G) is responsible for conducting research and managing these resources. In the search for a seafloor imaging system, ADF&G began experimenting with underwater video for scallop stock assessment in 1999. A prototype system consisting of a towed sled that held a camcorder in a pressurized housing and used battery-powered lights to image the seafloor was deployed for several years beginning in 2000. This system proved to have a number of limitations including insufficient image resolution, which did not allow consistent detection of small objects on the seafloor such as juvenile scallops.

The search for a more efficient system led ADF&G to the work of the HabCam project at the Wood’s Hole Oceanographic Institute (Cape Cod, MA, USA) and a system based on the GE1380C, a 1.4-Mpixel color digital camera from Prosilica (Burnaby, BC, Canada; www.prosilica.com). The camera runs up to 20 frames/s at full resolution and is capable of streaming data at a sustained rate of 125 Mbytes/s. Its GigE interface allows data transmission distances of up to 100 m over conventional Cat5e network cable or several kilometers using fiberoptic cable.

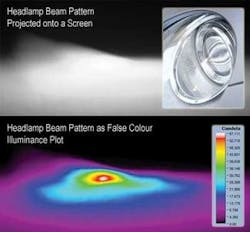

Imaging photometer tests automotive lighting

Ring Automotive (Leeds, UK) supplies bulb upgrades as replacements for the original lamps fitted to car headlights. Recently, the company needed to compare illuminance, chromaticity, and color temperature of its bulbs and competitive products to establish their performance benefits. In addition, Ring needed to qualify its lighting products and assess the lamps’ performance against the requirements specified in the applicable UN ECE R20 vehicle lighting regulations. Typically, illumination performance is measured by a goniophotometer, which achieves high accuracy but has a high capital cost, limiting it to standards testing laboratories.

The relatively slow measurement speed of a traditional goniophotometer also renders comparative testing of light sources to a slow process of limited scope. Instead, Peter Harding, Ring’s commercial director, used a ProMetric PM-1423F-1 CCD-based light and color measurement instrument manufactured by Radiant Imaging (Duvall, WA, USA; www.radiantimaging.com) to measure millions of angles simultaneously. Because the photometer views the whole illumination pattern at once, localized illuminance and color differences can be easily detected-artifacts that traditional goniometric measurements performed at defined angles might easily miss.

Face recognition uses sparse image representation

The conventional way to recognize a face is to record distance between the eyes, width of the mouth, and shape of the nose. But new research shows that recording random points is faster in crowds and more effective with disguises. That research by the University of California, Berkeley research scientist Allen Yang exploits a new algorithm called sparse representation. His Web site introduces the mathematical framework for classification and recognition problems in computer vision, especially face recognition. The idea is to cast recognition as a sparse representation problem, using mathematical tools from compressed sensing and L1 minimization. This leads to scalable algorithms for face recognition based on linear or convex programming. These algorithms produce striking results, recognizing subjects across large databases despite severe corruption and occlusion. For more information, go to http://perception.csl.uiuc.edu/recognition/Home.html.

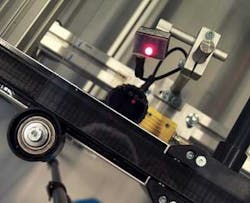

Vision tracks data in solar-cell production

At solar-cell manufacturer Würth Solar (Schwäbisch Hall, Germany; www.wuerth-solar.de), current production yield of modules using cadmium-indium-gallium-selenide (CIS) technology is 90% and rising. The company has produced the modules at its Marbach, Germany pilot installation since 2000. It has long collaborated with system integrator AIT Göhner (Stuttgart, Germany; www.ait-vision.com), and has recently implemented a data tracking system to enhance quality.

In producing CIS cells, the likelihood that a 120 × 60-cm module will have the desired output of approximately 80 W is not apparent until the end of the coating process. Therefore, quality data must be collected earlier in the process to determine the origin of defects. Each glass plate is assigned to an individual inspection station by means of Data Matrix code identification and quality data are recorded every third or fourth step of the production process.

The code is applied by laser engraving, which is difficult to read on glass because of the low contrast between the engraving and surrounding surface. After testing various vision systems, Würth Solar selected the In-Sight 5400 and 5100 ID readers from Cognex (Natick, MA, USA; www.cognex.com ), which proved able to detect barely visible codes and decode them at distances greater than 7 ft. The lasering is followed by 19 processing steps including the application of the base coating and subsequent laser structuring, which gives the plates their cellular shape.

A quality inspection is vital at this juncture, as the key production step immediately follows the washing of the plates. In this step, a CIS coating is applied to the plates. The company plans to install additional vision systems to increase production output from 600 to 1100 solar modules per day.