Camera Connections

Numerous digital standards for machine-vision camera interfaces offer increased data-transfer rates, deployment options, and challenges

In February 2008, Toshiba announced it would no longer manufacture HD DVDs, effectively leaving the Blu-ray Disc Association Blu-ray format the only high-density optical format disk. For those old enough to remember, the battle between the two standards is reminiscent of the VHS/Betamax format war of the late 1970s.

In both cases, it doesn’t really matter which technology is really better than the other, but simply which one is marketed more effectively and placed into the hands of the consumer the fastest. What have such optical-disk format battles to do with machine-vision and image-processing systems? Today, there are numerous ways to interface a camera to a computer.

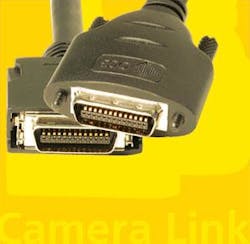

Indeed, what makes the choice of today’s camera interfaces and those that will appear in the next few years interesting is that these standards are being developed on three fronts: by consumer-based electronics companies, by computer vendors, and by those in the machine-vision industry itself. Developments emerging from consortia of these companies include USB, FireWire (1394), Ethernet, PCI Express, eSATA, Camera Link, and GigE Vision. Add to these the more established analog broadcast formats, such as RS-170 and all its variants, and the system integrator is faced with a plethora of standards from which to choose.

Multiple standards

This year, the choices increase on all three fronts as companies involved in these seemingly disparate markets rush to enhance the standards with interfaces that promise higher bandwidths and higher levels of software support. Unfortunately, in the development of the standards, companies do not seem to be discussing the potential benefits of the cross fertilization of ideas. This will lead to a number of different standards, all with much the same bandwidths.

Unlike the optical-disk wars, marketing and selling the most products will not determine the success of any particular standard. Machine-vision camera companies and system integrators will be left with numerous choices with which to implement the camera-to-computer interface of their systems.

Historically, several reasons exist for this situation. At present, the most common camera-to-computer interfaces used in the machine-vision industry include Camera Link, USB 2.0, 1394a/b, and GigE Vision. While Camera Link is a point-to-point interface that can support data rates up to 765 Mbytes/s (6120 Mbits/s) using 85-MHz transceivers, USB 2.0 and 1394b are serial bus standards that allow maximum data-transfer rates of 480 Mbits/s and 800 Mbits/s, respectively. The frame-based computer networking standard, GigE Vision, is based on Gigabit Ethernet and boasts a maximum data rate of 1000 Mbits/s.

For the system developer, the choice of camera interface is mandated by the application. At present, the data rate and level of determinism can be used to segment these standards. “Determinism is the ability of a cameras interface protocol to deliver the image to the host computer within a predictable amount of time and can become a problem for software developers who must interface machine-vision systems to process control systems that require very specific timing,” says Dwayne Crawford, product manager at Matrox Imaging. “When images arrive too late, the available time to process the image is reduced, resulting in missed frames. Camera Link, analog, and legacy digital interfaces such as LVDS and RS-422 are preferred interfaces for deterministic applications because the variance between the time data is transferred from the camera to the host (or the amount of jitter) will be less,” he adds.

Not just speed

What distinguishes these interfaces is the speed difference between them and the level of determinism that can be obtained using each one. “Packet-based protocols including GigE Vision, USB, FireWire, and PCI Express all exhibit high-levels of jitter since these packet-based protocols can all share the communications channel with multiple devices on the same link,” says Crawford.

For example, in the design of its STC-B33USB-based machine-vision camera, Sentech incorporates a progressive-scan CCD with 692 × 504 × 8 bits running at 60 frames/s. Since the data-transfer rate is 168 Mpixels/s, or 21 Mbytes/s, this is well within the limit of the USB specification. Similarly, the Grasshopper GRAS-03S3M 1394b camera from Point Grey Research offers a 648 × 488 × 8-bit CCD sensor running at 74 frames/s. Again, the 22.6-Mbytes/s data-transfer rate is well within the specifications of the 1394b standard.

FireWire and USB are serial-bus-based interfaces that support both isochronous and asynchronous data transfer. These modes are useful to both transmit image data (in isochronous mode) to moderate any jitter issues and control and set camera parameters (in asynchronous mode). Like USB and FireWire, the GigE Vision standard developed by members of the Automated Imaging Association (AIA) is also nondeterministic. Instead of using a serial bus interface, however, the GigE Vision standard is based on an extension of the well-established 10/100 Base-T Ethernet standard. In GigE Vision, isochronous transfer is also used to moderate the jitter issues by assigning fixed timeslots for data transfer.

With a maximum 1000 Mbits/s (or 125 Mbytes/s) maximum data-transfer rate, a true sustained data rate of 100 Mbytes/s is often achieved. Often, GigE Vision-based cameras do not even require this bandwidth. For example, the Prosilica GE650 GigE Vision-compliant CCD camera features a 659 × 493 × 12-bit imager running at 90 frames/s, producing 43.85-Mbytes/s data rate.

While serial-bus architectures such as USB and 1394b differ from the GigE Vision implementation in many ways, multiple-camera-based machine-vision systems can be developed using these standards. However, all these standards rely on a specific amount of bandwidth to be available on the bus or network to properly transfer image data. Overloading these buses or networks can have a detrimental effect on system performance, with captured image data being transferred more slowly or, worse, resulting in a loss of image data.

There are other differences that separate these standards, including cable length, whether power is supplied over the cable, and the level of software support. Cable lengths of Camera Link, USB 2.0, 1394b, and GigE Vision are approximately 10, 5, 4.5 m, and 100 m, respectively, while the only standard currently not supporting power is the GigE Vision standard.

To define the functions of machine-vision cameras and how to control them, only two software standards currently exist—the IIDC standard (for FireWire) and the GenICam standard (for GigE Vision, developed by the European Machine Vision Association). Companies adopting these protocols allow developers to write machine-vision software independently of the specific camera being used. “Major software vendors also supply the same functionality in their APIs for other protocols. In this way, the developer can change cameras without re-writing code (as with IIDC and GenICam) and change the interface standard without redeveloping their application,” says Crawford.

Upping the ante

Currently, these Camera Link, USB, FireWire, and GigE Vision interfaces clearly define a level of performance that system integrators can expect when specifying a camera. However, with the advent of high-speed multitap cameras, none of these standards can support data rates of higher than 765 Mbytes/s.

Realizing this, a number of higher-speed standards will need to be developed. Members of the Camera Link subcommittee of the AIA are now considering implementing a newer high-speed camera-to-digital interface to achieve data rates of 6 Gbytes/s (48 Gbits/s). Likely as not, this standard, once developed, will not be backward-compatible with the current Camera Link standard. However, the Camera Link committee is not alone in their pursuit of speed.

At the Intel Developer Forum last fall, for example, Intel demonstrated USB 3.0 that the company said would offer data-transfer rates of 4.8 Gbits/s (or 600 Mbytes/s). Although the specification is due to be released in the next few months, products based around the standard are not expected until 2009. However, this is still slower than the existing 10GBits/s Ethernet standard that will be available for consumer PCs in the same timeframe.

Indeed, introducing a specification for a standard and then realizing the design in hardware is another matter, as witnessed with the 2007 introduction of the 1394 Trade Association 1394c standard that supports 800-Mbits/s transfers over Cat 5 cable. Despite the fact that no chipsets are yet available, the IEEE upped the ante in December 2007 with a further upgrade known as S3200, designed to increase the speed of FireWire to 3.2 Gbits/s (or 400 Mbytes/s). Like 1394c, no chipsets are available. Unlike USB 3.0 and S3200, however, high-speed chipsets are available to those developing 10 Gigabit Ethernet (10GigE) products.

According to Simon Stanley, analyst at large of Heavy Reading (www.heavyreading.com), many manufacturers have identified the high cost and power demands of 10GigE transponders and physical layer (PHY) devices as the key barriers to making equipment more affordable. Transponder and PHY vendors have responded with devices that cost less to manufacture and use less power. As a result, 10GigE system prices are falling, and port shipments are rising as the per-user price of 10GgiE backbone connectivity falls below the $100 mark.

Still, for camera vendors expecting to sell machine-vision cameras at an average price of $2000, $100 may prove too expensive to implement. And, if such a standard was adopted, it would likely require endorsement by the AIA GigE Vision committee.

Computer standards can also be used to transfer data from cameras to host computers. In its x16 configuration, for example, the PCI Express bus can transfer a maximum of 4 Gbytes/s (250 Mbytes/s) in each direction over the interface. So far, however, using this interface to transfer data has only been demonstrated by Point Grey Research in a prototype camera using a x1 configuration.

The Serial Attached SCSI (SAS) standard could also theoretically be used as a camera-to-computer interface. Used to transfer data at rates of 375 Mbytes/s over 8-m cables, the standard and others, such as eSATA, are primarily developed to interface hard drives to computer systems and have not been adopted by camera vendors. No camera vendors currently support this interface.

“Though the PCI Express and SAS standards can demonstrate higher bandwidth capabilities, they are bus standards developed for use within the PC and utilize connectors that are not suitable for cameras. To truly be used within a machine-vision environment, further customization and standardization of the connectors, cables, and hardware would be required,” says Steve Kinney, director of technical pre-sales and support with JAI.

From a marketing perspective, who wins the camera-to-computer interface battle may have already been decided. Although the proposed 6-Gbyte/s data rate being considered by the Camera Link committee is fast, it may not be fast enough to support the high-speed multitap linescan and area-array imagers that will emerge in the next few years.

Despite this, the next Camera Link standard will surpass all others in defining the highest-speed deterministic point-to-point interface for the machine-vision industry. “Camera Link is and will still be the lowest-cost method to build the highest-performance camera-to-computer interface,” says Kinney. “This coupled with existing market momentum and the fact that Camera Link is the only interface to offer real-time signaling capabilities will maintain Camera Link’s market share for the foreseeable future.”

Musings From the Cable Guy

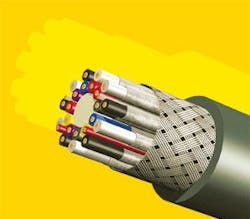

Whatever standard is the basis of your industrial vision equipment, whether Camera Link, PoCL, FireWire 400 or 800, USB, GigE Vision, or analog video coaxial, proper cable selection makes a significant difference in the success of your application. If you are using Camera Link, your choice of cable is easier because the Automated Imaging Association protects you by certifying the cable assemblies.

Although other cable assemblies such as FireWire, USB, and Category 5 cabling can be purchased at outlets such as Radio Shack, it is doubtful that you will find a suitable product for an industrial application unless your expectations and requirements are exceptionally low. While commercial products will work in commercial applications, industrial applications demand more-effective cabling methods. So when selecting a cable assembly for a challenging machine-vision application, confirm that the cable used was intended to be used in such an application.

Choose a cable assembly that meets the specified transmission requirements of your equipment, and choose only cable assemblies that are durable and robust with high flex life and protective jacketing. Many of the new custom jackets on industrial cables will allow temperature ranges from -50°C to 105°C. These are also resistant to ultraviolet radiation, resist abrasion, and weld slag burning.

Maintain the same standards for cable that you set for the rest of your equipment. Do not make an error and shortcut the success of your application by scrimping on the only corridor your data has to follow.

Bud Brown is director of new business development, Northwire Technical Cable, Osceola, WI, USA; www.northwire.com.

Camera Standards Reference Guide

Camera Link

Camera Link Specification

www.machinevisiononline.org/public/articles/articlesdetails.cfm?id=2028

Power over Camera Link

www.vision-systems.com/display_article/259246/19/none/none/Techt/Power-over-Camera-Link-products-emerge

Beyond Camera Link

www.vision-systems.com/display_article/308928/19/none/none/Feat/Beyond-Camera-Link

Miniature “Camera Link” connectors

www.vision-systems.com/display_article/218278/19/none/none/Techt/Cameras-feature-miniature-%22Camera-Link%22-connectors

Camera Link frame grabbers

www.vision-systems.com/display_article/312541/19/none/none/PRODD/Camera-Link-frame-grabbers-boost-performance

Universal Serial Bus (USB)

USB Specification

www.usb.org/home

USB 2.0 in machine vision

www.vision-systems.com/display_article/187952/19/none/none/WWICD/USB-ADVANTAGES-OFFSET-OTHER-INTERFACES

Intel demonstrates USB 3.0

arstechnica.com/news.ars/post/20070918-intel-announces-demonstrates-usb-3-0.html

FireWire (1394)

1394 Trade Association

www.1394ta.org/index.html

1394-based digital cameras

www.vision-systems.com/display_article/155667/19/none/none/FireW/IEEE-1394-based-cameras-promote-digital-imaging

Gigabit Ethernet

GigE Vision specification

www.machinevisiononline.org/public/articles/index.cfm?cat=167

Standards propel Gigabit Ethernet to the forefront

www.vision-systems.com/display_article/285208/19/none/none/Feat/Standards-propel-Gigabit-Ethernet-to-the-forefront

Driver options for GigE Vision cameras

www.vision-systems.com/display_article/319428/19/none/none/Feat/Driven-to-Distraction

1288 and GenICam Standards

emva.org/home/content/view/521/166/

PCI Express

PCI Express specification

www.pcisig.com/home

Overview of the PCI Express standard

zone.ni.com/devzone/cda/tut/p/id/3767

PCI Express 2.0 and 3.0

www.vision-systems.com/display_article/316042/19/none/none/Feat/Speeding-Up-the-Bus

PCI Express frame grabbers

http://www.vision-systems.com/display_article/276288/19/none/none/Feat/PCI-Express-captures-frame-grabber-designs