Straight Shooter

Two high-speed x-ray cameras inspect capped needles

With the plethora of government approvals now required in the production of medical items, manufacturers must deploy strict procedures to ensure that their products are properly inspected before they are shipped to consumers. For patients and others who need to inject certain drugs, prefilled drug-delivery systems that contain the vial and needle ensure the correct dose is delivered every time. Once packaged, these drug-delivery systems must be inspected to ensure that the needles capped atop the syringe remain perfectly straight. Since optical-based vision systems cannot be used for this, many pharmaceutical companies are considering the use of x-ray systems as a viable alternative. One company, located in Germany, recently contracted RSF Systems to install an x-ray-based system to perform this inspection.

“Once the drug-delivery systems are assembled, the needles are capped with a rigid plastic cover to keep them sterile,” says Rudolf Schmid-Fabian, president of RSF Systems. “In this process, the automatic capping mechanism may bend the needle or, possibly, the needle may protrude through the plastic cap. Because of this, x-ray imaging must ensure both the presence of the needle in the package and whether the needle has been damaged in the assembly process.”

After filling, assembling, and packaging, the final products are moved along an automated production line where clamping mechanisms present the final product to the x-ray system vertically. Two views of the package are required to properly detect whether these packaged needles are straight.

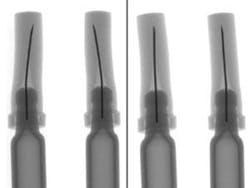

“Detecting two images at 60° to 90o to each other,” says Schmid-Fabian, “ensures that, should a needle be crooked, the defect will appear on either one of the images.” These x-ray sources are placed approximately 0.25 in. from the product to be inspected. To generate the required x-ray radiation, RSF Systems uses two 50-kV Apogee side-window x-ray tubes from Oxford Instruments that can produce a 35-µm focal spot size.

“This x-ray source was chosen for a number of reasons,” says Schmid-Fabian. “First, low-density materials, such as those used to pack needles, require less x-ray energy than metals or very thick parts. Thus, these can be imaged using a 50-kV source. Also, since the finite spot size of the x-ray source creates a penumbra around the edges of the x-ray shadow, a smaller spot size and a shorter object-to-detector distance decrease the minimum feature size detectable at the image plane,” says Schmid-Fabian.

Custom power

To properly image the needles, however, required the development of a custom controller and power supply that allows the x-ray beam to be switched on and off within a few milliseconds. To get a sufficient number of x-ray photons into each sensor element, the needles must be held stationary in the x-ray system for at least 100 ms while the x-ray beam is switched on.

To detect the images, two Rad-icon Shad-o-Box x-ray cameras are placed perpendicular to each other approximately 0.25 in. from the conveyor and thus 0.5 in. from the x-ray source. This results in an image resolution of approximately 10 lp/mm at the image plane. “Since each camera requires 370 ms to capture, transfer, and then clear an image once the needle packages are exposed,” says Schmid-Fabian, “the maximum line speed of the conveyor is limited to inspecting approximately four products per second simultaneously. Of course, deploying multiple x-ray-based vision systems on the production line can increase throughput.”

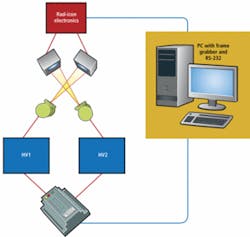

As needles traverse the conveyor belt, the conveyor controller sends a TTL-signal that triggers the custom x-ray controller to switch the x-ray beam on for a defined time. This triggers images taken by the two x-ray cameras (see Fig. 1). A PXD 1000 digital frame grabber from CyberOptics Semiconductor controls the readout cycles and collects the digitized sensor data. This PCI bus card provides a 32-bit parallel connection to the cameras. Specially designed software allows viewing and storage of images.

Capturing images

In the system, each of the x-ray remote sensors features 500 × 1024-pixel photodiode-array sensors with 48-µm pixel spacing. An integral phosphor screen shields the sensor from ambient light and converts incident x-rays to visible light that is sensed by the silicon photodiodes. As images are captured by these cameras they are transferred to a host PC using a 12-bit digital interface.

After images are captured by the host PC, they must be processed to ensure that each needle is straight. As x-rays pass though the plastic cap and are attenuated by the needle, the captured images of the needle are dark. Since the plastic cap will attenuate these x-rays to a lesser extent, simply adjusting the contrast of the image can produce an excellent profile of the needle within the cap (see Fig. 2).

Two views of the needle are needed. After images are captured and transferred to the host PC, a line profile of each of the images is calculated from the horizontal pixel intensity across the image. Then, the center and the orientation of the needle with respect to the needle body are determined. If one of these orientations is not centered, then the PC generates a serial command to another PC located on the production line. This PC then controls the handling mechanism that presented the needles to the x-ray system.

If a needle should fail, the PC orders the handling actuator to drop the needle into a reject bin. If the needle passes inspection, it is moved further along the production line to the packaging station. At present, RSF Systems has deployed a number of these systems in Germany and is currently working with other pharmaceutical vendors to deploy similar systems.

null