Word on the Wire

With more than 1000 FireWire cameras available, choosing the correct product for a specific application requires careful research

Now more than a quarter century after its introduction, Apple Computer’s FireWire serial bus, an interface primarily developed to interconnect computer peripherals, storage devices, and consumer-electronics units, has become firmly established as one of the most popular interfaces for machine-vision cameras. Standardized as the IEEE-1394a and b specifications, this interface supports data rates as fast as 800 Mbits/s, with planned extensions that may increase this data rate to 3.2 Gbits/s.

Indeed, the success of this interface has resulted in more than 1100 different varieties of FireWire cameras being offered by greater than 80 vendors! Luckily, Damien Douxchamps, a senior researcher at Cyberdyne, has complied a list of nearly all the currently available FireWire cameras worldwide and posted them on his Web site (http://damien.douxchamps.net/ieee1394/cameras/#FAQ).

While manufacturers can easily update their information on the site, potential purchasers of FireWire cameras can dynamically quiz the database listing by manufacturer, sensor size and type, optics used, and camera features such as external triggers, I/O, and on-board memory. This valuable resource is a great starting point for those wishing to purchase a FireWire camera but only goes part of the way in answering all the questions that need to be answered when choosing a camera.

Full-frame imaging

One of the main problems in evaluating the performance of these cameras is the lack of technical data supplied by vendors. Indeed, despite years of work developing the European Machine Vision Association (EMVA) 1288 standard, designed to properly characterize such cameras, only two camera vendors—PCO AG and Basler Vision Technologies—and one CMOS imager vendor—Awaiba CMOS Image Sensors—have released 1288-compliant datasheets describing their products (www.standard1288.org).

One of the most important factors in determining whether a FireWire camera is suitable for a specific machine-vision application is the type of imager used in the camera. For CCD cameras, the three most commonly available image sensors are full-frame imagers, frame-transfer imagers, and interline-transfer devices. Because the architecture of these devices is radically different, cameras developed using them target several diverse markets.

Full-frame imagers, for example, use all of the silicon area of the CCD to capture an image, and, because of this, they exhibit both high sensitivity and dynamic range. The Kodak KAF- 3200, for example, is a 2184 × 1510-pixel full-frame CCD image sensor that features a dynamic range of 78 dB, a 100% fill factor, and quantum efficiency of up to 80% (at 650 nm).

While such imagers exhibit high-performance characteristics, the nature of their design means that they must be used with a shuttering mechanism; otherwise images read out will smear. Because of this, camera vendors such as Princeton Instruments offer these cameras with built-in mechanical shutters. The Princeton Instruments MegaPlus ES3200 FireWire camera, for example, uses the KAF-3200 to digitize 2184 × 1510 × 12-bits/pixel at 12 frames/s.

Of course, these data rates do limit the potential applications of cameras. But, because of their high-fidelity image reproduction, they are ideally suited to medical, scientific, and ophthalmology applications, where image quality, not image-capture rates, is of high importance.

No shutter required

To alleviate the necessity of electromechanical shutters, imager vendors developed the concept of frame-transfer devices. These devices consist of an active light-sensitive image area that comprises half the area of the device and a shielded storage region that makes up the other half. In operation, photons are converted to charge in the image area during image integration and then transferred to the storage area. This charge is then read out from a readout register.

Devices such as the CCD97, part of the L3Vision2 series from e2v Technologies, operate in this manner. With 512 × 512 active pixels, the 11-frames/s device has been used by Photometrics in its QuantEM:512SC electron-multiplying CCD (EMCCD) FireWire camera, which has been primarily developed for fluorescence imaging. While these devices do eliminate the need for mechanical shutters, they require twice the silicon area of their full-frame counterparts, which, of necessity, increases the cost of the devices, all other factors being equal.

To increase the speed of CCD-based cameras for machine-vision systems, designers are turning to interline CCD cameras, most notably those produced by Sony. In these devices, light-sensitive columns of pixels are interspersed with storage columns. Because the complete image is not read into a shielded memory region, as with frame-transfer devices, electronic shutter times are faster and image smear is reduced dramatically.

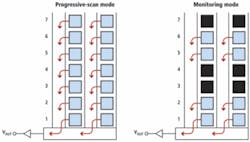

Sony’s ICX098BL is typical of such devices. With this interline CCD image sensor, square 5.6 × 5.6-μm pixels in a 659 × 494 array, the device can be operated in two modes. In progressive-scan mode, all the pixel signals are output independently in 1/30 s, resulting in a 30-frames/s frame rate. In so-called monitoring mode, pixel signals are output in approximately 1/60 s by repeating readout pixels and nonreadout pixels every two lines, lowering vertical resolution but increasing read-out speed (see Fig. 1). The Imaging Source has used this sensor in its DMK 21AF04 monochrome FireWire camera.

CMOS benefits

While many camera vendors use CCDs in their machine-vision cameras, others have tied their chariots to CMOS workhorses, most notably those from Aptina Imaging. Unlike CCD imagers, CMOS devices are based on active-pixel arrays, where each pixel site contains an individual photo-site and readout electronics. Because of this, the fill factor can never reach 100%. Although the performance characteristics of these devices is generally less than CCD imagers, the integration of image sensor and readout electronics onto a single device results in a lower cost and simpler camera designs.

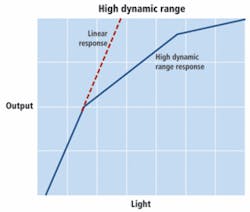

In many cases, such as high-speed and low-light-level imaging or where region-of-interest (ROI) image capture is required, CMOS-imager-based cameras have found strong market niches. In the design of its FireWire-based LW-WVGA-G-1394 camera, for example, Imaging Solutions Group (ISG) has used a Aptina Imaging MT9V022—a 752 × 480 CMOS imager with 6 × 6-µm pixels that can run at 60 frames/s and faster in ROI mode. The MT9V022 pixel response can be configured for either linear light response with approximately 55 dB of dynamic range or for high-dynamic-range response with as much as 100 dB of dynamic range by controlling the slopes of a three-segment, piecewise, linear pixel response (see Fig. 2).

However, it is not only the type of sensor used in each camera that must be carefully considered when specifying a FireWire camera. It is also the size of the imager itself. Today, many available FireWire cameras use 1/4-, 1/3-, 1/2-, or 2/3-in. CCD or CMOS image sensors. In these cameras, the theoretical maximum resolution achievable with a perfect lens depends on not just the number of available pixels in the imager, but also on the pixel size of the imager. A comparison of four cameras that all use interline-transfer CCDs from Sony, all with different sensors sizes and pixel pitches, illustrates this dramatically (see table).

While these cameras have been selected at random from the camera products offered by these vendors, the table highlights the relationship between the number of pixels used in the imager and the camera, size of the imager, and achievable resolution in line pairs per millimeter. Of course, choosing a camera based on these parameters alone is not enough. System developers must also take into account the application for which the camera will be used.

Since cameras with different image-sensor sizes using the same focal-length lens will each yield a different field of view, cameras with smaller sensors can use shorter focal-length lenses to obtain the same angular coverage as cameras with larger sensors with longer focal-length lenses. Angle of view can be calculated if the focal length and image size are known. If the distance of the object is finite, however, this angle is not used and the field of view calculated using a simple formula found at http://machinevision.navitar.com/ pages/product_information/low_mag_video_lens/ low_mag_optical_character.cfm?nav4=true.

Because no lens is perfect, the proper choice of a lens can radically alter the achievable resolution of the camera system. In choosing a lens, system developers must study the modulation transfer function of each lens to understand how, when using a particular lens, contrast will be reduced as a function of spatial frequency.

Resolution vs. speed

With FireWire cameras the system developer is required to trade off resolution for speed. Because the maximum theoretical bandwidth of the 1394a interface is 400 Mbits/s and that of 1394b, 800 Mbits/s, it is rare to find FireWire cameras that use any type of image sensor faster than 100 frames/s. Two cameras, the Pike F-032B from Allied Vision Technologies and the Dragonfly Express DX-BW from Point Grey Research, both use the progressive-scan interline CCD from Kodak to offer VGA resolution and a speed of 200 frames/s.

Given the 640 × 480-pixel resolution and 8- or 10-bit/pixel output of the device, it can be seen that the total maximum output bandwidth of the camera is 200 × 10 × 640 × 480 or approximately 615 Mbytes/s, well within the 800-Mpixel/s limitation of the 1394b interface. While the Dragonfly Express DX-BW supports the standard 4.5-m cable lengths of the 1394b specification, the camera can also be used with high-performance cables from Unibrain and others that extend this distance to greater than 10 m. For those wishing to span longer distances, Unibrain also offers a glass optical fiber repeater that extends the S800 (800 Mbits/s) transmission of 1394b bus to 550 m. Such an option is also supplied by Allied Vision Technologies in all of its Pike and Stingray cameras to allow the sensor to be used up to 500 m from the host computer.

While the performance of these cameras relies on the specific hardware used, controlling the cameras is left to the specific APIs offered by the manufacturer or other third-party software vendors. Some vendors provide IIDC (formerly DCAM) APIs that support only their range of cameras, while other third-party vendors such as A&B Software provide software such as the company’s ActiveDcam, which supports multiple IIDC-compliant FireWire cameras. Developers wishing to use different cameras from a variety of vendors can therefore use software such as A&B’s ActiveDcam to develop their Visual C++, Visual Basic, VB.NET, and C# based programs, while at the same time maintaining full control over all the camera settings of different camera products.

null