FACTORY AUTOMATION: Image-based scanner boosts read rates

At its facility, West Liberty Foods (www.wlfoods.com) processes raw turkey, pork, beef, and chicken meat into 6- or 10-ft logs that are first cooked, then sliced, boxed, and refrigerated. In the past, a 1-D linear barcode was applied to each package at the slicing station. However, the laser barcode readers proved unsuccessful because the 200 ft/min line rate of the conveyor, the variety of shapes and sizes of boxes, and the different positions of the barcodes on each box resulted in high reject rates.

Although attempts were made to ensure labels were accurately placed on each box, the barcode read rate could not be improved beyond 93%. And at up to 25,000 boxes per day, the reject rate of 7% became unmanageable. A second scanner was added, but improvement was marginal.

To overcome these problems, Echo Automation & Controls (www.echogroupinc.com) suggested deploying a DataMan 500 image-based code reader from Cognex. This image-based approach can read 1-D codes, provide higher read rates, and read 2-D Data Matrix codes that contain a larger amount of data than 1-D barcodes. Achieving up to 90 decodes/sec, the DataMan 500 employs liquid-lens autofocus technology to maximize the depth of field of the imaging system, providing greater reliability in applications where package position varies.

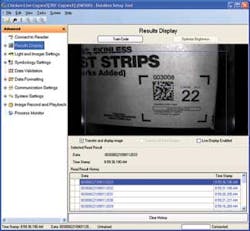

Echo Automation connected the reader to a notebook computer that was interfaced to the network, and used the graphical user interface (GUI) on the computer to view captured images in real time and adjust aperture, gain, and focus. Because the DataMan 500 uses Power over Ethernet, no external power supply was necessary.

After replacing the existing linear barcode readers with the image readers, West Liberty Foods saw an immediate improvement to a 98% read rate. After redesigning the company's 1-D barcode labels as 2-D Data Matrix codes, a 99.99% read rate was achieved. In the final installation, two DataMan 500 units were employed to ensure 100% read rates. "The only boxes that cannot be read now are those where the code is missing or severely damaged," says Dave McDowell, director of information technology for West Liberty Foods.

The DataMan 500 acquires an image of the entire box and locates the code regardless of its position and orientation. Since the code can be printed directly on the box, this saves time and money by eliminating the need to manually apply a label to each box. If a code cannot be read, the DataMan 500 automatically records failed images and stores them on a server. West Liberty engineers can then inspect the images to see why they failed. "In nearly every case there is either no code or the code is smashed or wrinkled," says McDowell.

West Liberty Foods plans to deploy the DataMan 500 readers at its Mount Pleasant, Iowa, facility where they are expected to provide more accurate production counts and reduce the time handling rejects.