Optical filters reduce glare in automotive canister machine vision inspection application

Chris Walker

When manufacturing metal canisters for the automotive industry, a bead of sealant is often required. It must be applied to the interior of a cylindrical piece of metal so other parts can be attached. It is important to check the presence and uniformity of this sealant bead to determine its position, and measure its width for consistency around the circumference of the cylinder.

At a production rate of 900 parts/min, manual inspection of the seal is both time consuming and labor intensive and automation of such parts is imperative.

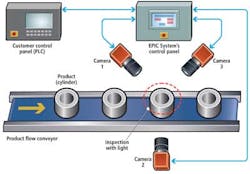

To perform this task, EPIC Systems (St Louis, MO, USA; www.epicmachinevision.com) has developed a machine vision system to reduce the number of false failures. The quality control process required the detection of the presence and position of the sealant bead, while measuring its width around the circumference of the 10mm diameter canister. Three In-Sight vision systems from Cognex (Natick, MA, USA; www.cognex.com) were arrayed so each camera captures a 120 degree segment of the interior surface of the canisters, as they move along a conveyor (Figure 1).

EPIC Systems used two different machine vision inspection methods to simultaneously inspect the interior surface of the cylinder and only pass the part if both methods indicate the part is good.

First, edge tools from the Cognex Vision Tools software are used to locate the top edge and the bottom edge of the sealant and the top edge of the canister. Calculations are then performed to determine the width of the sealant bead and the distance of the bead from the top edge of canister. Histogram tools count the number of pixels meeting certain requirements within a specific area. By counting the black pixels within the area the bead is located, the presence of the bead and inconsistencies such as holes or gaps in the bead can be determined.

Overcoming glare

Glare is the reflection of light that washes out image contrast and blocks image features. This issue presented a problem due to the limited amount of space within the canister. In many applications, glare can be eliminated by correctly positioning lighting and cameras, but in this case, there was not enough room to accomplish this.

Furthermore, the canister may vary in appearance due to changes in the raw material and manufacturing process. In the original application, a digital image filter was used to highlight the glare. The filter would threshold the image, based on the result, to reduce the impact of glare.

However, the specification for the vision system was for 0% false positives and the inevitable result was a certain number of false failures. The false failure rate was initially 400 parts per million. Although low, it was necessary to manually inspect every rejected part which, was untenable given the throughput of the line.

To overcome this glare, a machine vision system was developed that employs polarizing filters. When light that is polarized in a specific direction hits a diffuse surface, most of the light becomes randomly polarized and reflects in random directions. Areas where strong reflections exist, however, maintain much of the incident light angle of polarization.

By placing a polarizing filter on the camera lens, rotated 90 degree relative to the light source angle of polarization, the strong reflections of polarized light are absorbed by the camera lens filter. Diffused light from the area where no glare exists is then transmitted to the camera lens, reducing the effect of glare.

Glare can often be reduced by using a single filter. The cylindrical geometry of the object under inspection, however, interfered with the ability to use a simple 1D polarizer for a multiple camera system. This glare was reduced by using a setup of polarizing filters from Midwest Optical Systems (Palatine, IL; USA; www.midopt.com).

Polarized light

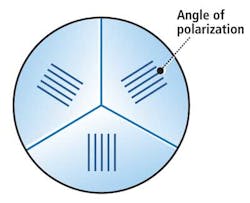

Although metallic surfaces will not polarize light, light reflected from non-metallic surfaces can become polarized at low incident angles. At an angle known as the Brewster Angle, the reflected light is completely polarized. To eliminate glare caused by both direct reflections of light and the reflected light from low-incident angles, three pie-shaped polarizers were fit into a fiber-optic end effector (Figure 2).

Each pie-shaped polarizer angle serves to geometrically reduce the reflected light from low-incident angles, for a specific camera. The system reduces direct reflections of light by being cross-polarized by a polarizer filter mounted on the camera lens (the PR032 from Midwest Optical Systems). This allows a single light source to be used while optimally polarizing that light source for each individual camera.

If only one polarizer was placed on the light source, direct reflections of light would have been reduced but not low-incident reflected light because that is more of a geometry problem. In the latter scenario, turning the single polarizer on the light source would cause two of the cameras to exhibit no glare but not the third camera.

The light angle of polarization effects how the light reflects off of a glossy surface at low-incident angles. Thus, three geometries were optimal. Linear polarizers can be understood as a lattice or vertical blinds on a window. The most ideal polarizer geometry for this 360 degree application would be a polarizer - like a dart board (with concentric circles).

In most applications you would not want to polarize the light source with multiple polarizers. In this case, most of the light for each pie-shaped region benefits only a single camera. Each pie-shaped region of the light shines on the side of the cylindrical object that each camera is inspecting. All three cameras were cross-polarized with PR032 polarizers from Midwest Optical Systems.

To eliminate UV or IR light being generated from the Xenon light source, the cameras were setup to employ BP550 UV+ NIR block/visible pass filters. In addition, an AC380 anti-reflection and scratch-resistant acrylic protective window from Midwest Optical Systems was used as a protective surface for the fiber-optic end effector.

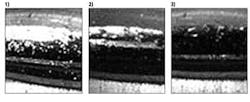

The use of optical polarizers and filters made it possible to simplify the machine vision algorithm by reducing the digital image filtering required (Figure 3). This condensed inspection time from 85 to 65ms, enabling a potential 31% increase in line speed to approximately 900 parts/min. EPIC Systems has installed similar systems on six different lines with diverse vision systems to match varying line speeds.

The algorithm has been tested on both the Cognex In-Sight Micro 1400 and High Speed In-Sight 5600 vision system. The In-Sight 5600 achieved an inspection time of 38ms, which enables a production speed of 1200 parts/min.

Chris Walker, Project Manager, EPIC Systems (St Louis, MO; www.epicmachinevision.com)

Companies mentioned

Cognex

Natick, MA, USA

www.cognex.com

EPIC Systems

St Louis, MO, USA

www.epicmachinevision.com

Midwest Optical Systems

Palatine, IL, USA

www.midopt.com

Vision Systems Articles Archives