Test standards ensure the safety of LED lighting products

Andy Reed

LEDs have benefited from exponential performance improvements during the past 20 years due to their better efficiency and lower operating costs compared to incandescent and gas-discharge lamps. Because LED lights are made of a monolithic semiconductor material, they also are inherently more rugged than filament- or ballast-based lights. This has made LED lights extremely useful in industrial markets where uptime is a primary concern. Finally, LED lights can also be designed to generate almost any wavelength or color of light from the UV through the IR spectral band.

Most white LED lights manufactured today start as a blue LED with additional phosphor coating to create a broadband white light source. This has led to the development of brighter blue LEDs. Unfortunately, as the white LED becomes more prevalent, it also increases the danger of UV damage to human eyes. Above certain luminosities, UV, visible, and IR light can cause considerable photo-biological damage to eyes.

Compliance testing

Manufacturers of products containing LED lights know that governments around the world require their products to be tested to guarantee that ultraviolet (UV) and infrared (IR) light output does not exceed specific safety levels. In response, the International Electrotechnical Commission (IEC; Geneva, Switzerland; www.iec.ch), with input from the IEEE (New York, NY; www.ieee.org) and other industrial groups, developed an international standard - IEC62471 "Photobiological Safety of Lamps and Lamp Systems" - in 2009 to protect people from photobiological damage caused by LED light.

The standard requires that all lamp designs, including LED and all luminaires, have their output tested and documented from 200-3000nm by a certified laboratory to prove the light does not exceed safety output thresholds defined by a certain luminosity at a given distance. Products bearing CE, UL, CCC, or other national marks that do not have documented proof of IEC62471 compliance can be confiscated and excluded from sale, and the manufacturer fined.

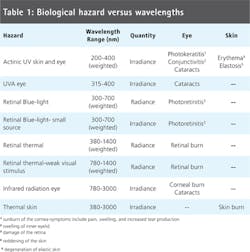

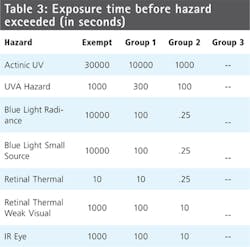

Based on tests documented in the IEC62471 standard, LED lights are classified within one of four risk categories and must be labeled accordingly. There are various biological hazards that are considered within different wavelength ranges in accordance with the standard IEC/EN 62471. The biological effects on both the eyes and skin are tabulated in Table 1. Sources are classified into four groups according to hazard, based on the emission limit and permissible exposure time before the hazard is exceeded (Table 2). To determine the risk group of a source, its spectral irradiance or radiance has to be measured at a specified distance, weighted with spectra and maximum allowed exposure time, which is compared to different exposure limits. For continuous sources, the exposure time limits are shown in Table 3.

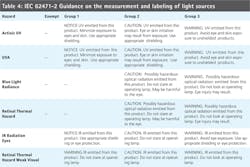

IEC 62471-2 "Photobiological safety of lamps and lamp systems - Part 2: Guidance on manufacturing requirements relating to non-laser optical radiation safety" provides further guidance on the measurement and labeling of sources and is a useful supplement to IEC/EN 62471 (Table 4).

Worldwide adoption

Today, Europe, Canada, and parts of Asia require that all lights be tested and documented to the IEC62471 standard. Unfortunately, many manufacturers are unaware of this requirement. Believing their products comply with all relevant standards, these OEMs routinely apply CE marks for products to be sold in Europe, for example. However, should a problem or lawsuit arise, and the OEM does not have certified test documents, these products will be removed and prohibited from sale and raise the potential of fines, regardless of whether the product actually complies with IEC62471. In other words, testing and documentation are a requirement-not an option-when it comes to "safe for sale" marks in most developed markets around the world.

While many countries require compliance with IEC62471, each country has the right to alter it as necessary. To help global manufacturers comply with the different requirements, the International Electrotechnical Commission for Electrical Equipment Safety (IECEE, Geneva, Switzerland; www.iecee.org) developed a Certification Body (CB) Scheme. The CB Scheme allows for mutual recognition of LED test reports and IEC62471 compliance certificates among 53 different countries.

Testing LEDs

In September 2013, Smart Vision Lights (Muskegon, MI, USA; www.smartvisionlights.com) started testing its own LED products as part of the process for legally applying marks of conformity, such as Europe's CE mark, to the company's lighting products. Today, the company only designs and manufactures LED lights that comply with IEC standards, including the IEC62471 photobiological safety standard.

Smart Vision Lights' LED testing lab includes a spectroradiometric system from Gooch & Housego (Ilminster, England; http://goochandhousego.com) that consists of an OL 750-M-D double monochromator with an integrating sphere and germanium, lead sulfide and silicon detectors for performing accurate optical radiation measurements. Smart Vision Lights' test equipment is regularly calibrated and verified by Intertek (London, England; www.intertek.com) to meet the minimum accuracy requirements published in the IECEE's CTL Decision Sheet 251B -Measurement Accuracy. This equipment enables technicians to independently measure and validate IEC62471 data, including radiance and irradiance of optical radiation from 200-3000 nm wavelengths.

Complying with the IEC62471 standard assures designers purchasing LED lighting components that they are safe to operate and can be sold worldwide. While not every company around the world is aware of the need for IEC62471 compliance, large companies and governmental agencies are well aware of the need to comply with IEC safety standards. Cognex Corporation (Natick, MA; www.cognex.com), for example, recently secured a contract to build a postal sorting system based on presenting IEC62471 documented compliance of Smart Vision Lights' LEDs.

AndyReed, Smart Vision Lights (Muskegon, MI, USA; www.smartvisionlights.com)

Companies mentioned

Cognex

Natick, MA, USA

www.cognex.com

Gooch & Housego

Ilminster, England

http://goochandhousego.com

International Electrotechnical Commission (IEC)

Geneva, Switzerland

www.iec.ch

International Electrotechnical Commission for Electrical Equipment Safety (IECEE)

Geneva, Switzerland

www.iecee.org

Smart Vision Lights

Muskegon, MI, USA

www.smartvisionlights.com

Vision Systems Articles Archives