Two-dimensional barcode systems

Two-dimensional barcode systems

By John Haystead, Contributing Editor

Automatic identification labels, or barcodes, are familiar to every supermarket visitor. But in manufacturing tracking applications, barcodes are often not up to the task. They provide limited data, often take up too much space to allow small parts to be coded, and are difficult to print on some surfaces. And, if the barcode is damaged, data retrieval can be impossible.

To deal with these problems, International Data Matrix (ID Matrix; Canton, MA) has developed a two-dimensional (2-D) symbology. Now in the public domain and approved by the Automatic ID Industry Association, the data matrix code, along

with other 2-D coding symbologies, is making barcode labeling easier to use in industrial applications

Two-dimensional symbologies encode information along two axes, as opposed to conventional single-axis barcodes that can offer data capacities in the 2?3-kbyte range. As such, they in effect function as on-part databases. While a typical barcode offers six numeric characters per inch, the data matrix code provides up to 15 alphanumeric characters in a 1/4-in. square. This coding is useful in applications requiring small code marking size and low contrast printing.

Data matrix code is contained in a checkerboard pattern with information encoded as light or dark areas. Data capacity is a function of the type of character, up to 3116 ASCII characters can be encoded in a single data matrix symbol, and up to 16 matrices can be concatenated. Scalability is from 0.0002 in. to 14 in. square.

Data matrix symbology has been adopted by the semiconductor-equipment-manufacturing industry as a standard format for identifying silicon wafers and by the Electronic Industry Association for PC boards. The Auto Industry Action Group (AIAG) has also adopted data matrix symbology for tracking parts with less than 1/4 in. per side, and the European Organization for Standardization has voted to fast-track the adoption of the symbology as a European standard this year.

Other 2-D symbology codes exist. The Symbol Technologies (Holtsville, NY) PDF417 has a stacked-barcode approach that encodes information in the varying widths of individual bars. The AIAG has endorsed PDF417 for areas greater than 1/4 in. per side. Edge detection is a critical element in reading PDF417 code because both bars and spaces are read as either thick or thin elements. This leads to a limitation characteristic of standard barcodes?printed surfaces must have an 80% contrast between the bar image and the printed surface. PDF417 is generally used in high-information- volume applications where contrast is not a problem. It also has particularly good data-recovery characteristics if symbols are damaged.

A major distinction between data matrix symbology and PDF417 is that PDF417 uses a look-up table to decode each segment into one of 929 possible values. Data matrix code, on the other hand, generates machine-executable code eliminating this translation step. According to Dennis Priddy, president of ID Matrix, OAny graphic language can be encoded; 16-bit Kanji becomes 16-bit data matrix code.O

Another 2-D symbology, Maxicode, developed and employed by UPS (Danbury, CT), has been recommended by the AIAG for high-speed sorting and tracking in the transportation industry. Maxicode has a fixed physical size (1 1 in.) and a fixed 1000-character capacity. The symbology incorporates a bullseye in the center of its matrix to aid in camera acquisition and lock.

Readers and controllers

Several companies design and manufacture code readers for 2-D code symbologies in different form factors including application-specific,

general-purpose, fixed-position and hand-held, discrete systems, and plug-

in-board versions.

Code readers for Maxicode and data matrix code use CCD cameras to acquire the matrix image code in one pass. PDF417 is more commonly read with laser scanners. OPeople are comfortable with lasers, and they give you a more flexible depth of field than CCDs,O says Priddy. On the downside, PDF417 code readers must scan multiple rows of code that must be aligned with the scanner within a 5? window. Linear CCD code-reading cameras are also available, but code readers have a single row of CCDs instead of a full array. These readers scan code symbols like laser scanners.

In manufacturing, 2-D code system readers verify individual part or product serial numbers and log them to and from process steps. These data are then fed into a factory control database where they become part of the quality-control process. Hewlett-Packard (San Diego, CA) uses barcode readers to track the production of ink-jet cartridges. Invisible data matrix code with each cartridge?s serial number is read and tracked through manufacturing and printed on the final package (see OBarcodes track ink-jet cartridges at Hewlett-Packard,O)

ID Matrix?s code readers range in price from $2500 to $9000, depending on application and capabilities required. Its VS-1 and VS-2 In-tray Matrix Code Readers are fixed-station, verification readers designed for the semiconductor industry. The VS-1 reads and verifies the codes marked on ICs held in JDEC trays. Up to six reads per second are possible; an audible tone and visual display button indicate successful read and decode. A built-in RS-232 port passes data to the host.

The SR20 is a general-purpose symbology controller used in applications where there is significant damage to a part or symbol. The VME-based system has decode rates up to 1200 parts per minute and RS-232, discrete I/O, VME, and optional high-speed serial link to a PC-based Windows interface program.

System configurations

In all of the system configurations, an industrial video camera captures the 2-D field of view and passes the image through an analog-to-digital converter (ADC) to the central processor. The level of integration of the ADC is dependent on the system. In the small MX series of controllers, the frame grabber is a single board with integrated ADC. The SR20 is a VME system with a dedicated ADC board. The MX series is based on a PC architecture. All of the company?s products use Microsoft Windows as the user interface.

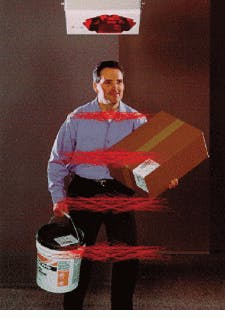

One novel hands-free laser scanner from Metrologic Instruments (Blackwood, NJ) uses holographic techniques to allow packages to be scanned at distances of up to 2 meters. The IS5700 and IS5800 scanners use a single rotating disk that replace beam-shaping lenses and use polygon mirrors to

allow the system to simultaneously

acquire barcodes at different focal lengths from the scanner (see OHolograms take on barcode scanning,O).

But it?s not electronics or system configuration that distinguishes one vendor?s code reader from another? it is the method of image processing and pattern recognition used. OEveryone uses the same kind of hardware and components,O says Priddy. The method of extracting the ones and zeros is fairly common and is published in the specification, but algorithm design is critical.O All symbology developers have evolved their own proprietary algorithms for image acquisition and analysis of codes. These algorithms may be licensed for incorporation in other products.

Two dimensional or stacked barcode symbols such as Data Matrix, PDF417, and Maxicode are composed of square-like elements that offer increased data capacity over traditional barcodes such as Code 128.

Two-dimensional symbologies are making barcodes easier to incorporate into industrial applications.

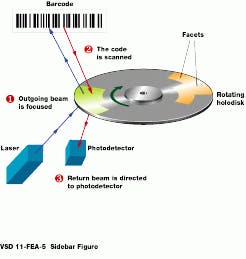

Holograms take on barcode scanning

Besides being used to create 3-D images, holograms can be used as lenses in holographic scanners. In such systems, a single rotating disk (holodisk) replaces the traditional beam-shaping lenses and rotating polygon mirrors of a traditional laser scanner. The disk has multiple holograms or facets on it that focus a laser scanning beam at a different distance from the scanner. When the disk is rotated, each holographic sector, as it passes over the laser beam, scans it across any barcode present, collects some of the reflected light, and records the barcode information.

While typical laser scanners operate at single focal lengths, holographic scanners, with their multiple facets, can scan over many focal lengths, allowing the scanner to overlap focal lengths at up to several feet.

In the design of the IS5700/IS5800 holographic scanner, Metrologic (Blackwood, NJ) developed a holodisk made up of between 14 and 20 facets, depending on the individual scanner design. Focusing, scanning, and reception transfer functions are embedded in each of these facets.

In focusing, each of the facets can have its own plane of focus. In the IS5700/5800 scanner, this can vary from 700 mm from the scanner face to more than 2 m. The light-receiving area of each facet is tailored to receive the right amount of light from each of the focally distant planes and directs it to a photo- diode. In this way, the system`s signal processor can be tuned for a given signal level to provide an exact reproduction of the barcode image.

By using a rotating optical disk with multiple facets, the Metrologic holodisk-based IS5700/5800 scanner can operate at distances from 700 mm to more than 2 m.

Barcodes track ink-jet cartridges at Hewlett-Packard

The Hewlett-Packard (HP) Ink Jet Business Unit (San Diego, CA) has installed International Data Matrix (IDMatrix) readers as part of the automated manufacturing and tracking system used to monitor and control the manufacture of ink-jet cartridges used in the company`s 650C through 1600C lines of ink-jet printers. These include nine different product variations with each ink-jet cartridge containing up to 20 components in the cartridge body alone. Print heads are manufactured at a separate location.

HP`s San Diego plant manufactures both black and color ink cartridges, with each cartridge conveyed individually along parallel manufacturing lines. Identical cartridges may be assembled from different component lots or constructed using different tooling. As each component is manufactured and assembled, it is continuously tracked and monitored for quality problems. In addition, essential data elements, such as lot numbers of incoming components and the locations of parts at various points in the process, are collected. According to HP development engineer Martin Kuetzing, the small size of the data matrix symbol and its data-capacity and error-correction capabilities were key in choosing the 2-D barcode technology.

Because both the print head and cartridge body are made from an opaque black plastic, Domino/Amjet printers generate the data matrix code using ultraviolet ink. Domino recommended against the use of pigmented inks that might result in increased maintenance or reliability problems. Laser etching was ruled out due to low contrast and capital costs. Algorithms in ID Matrix`s readers enhance the low- contrast UV images so that the barcode can be read. Finally, the original data matrix symbol is also printed on the product`s package for future traceability. HP has now designated the system as its corporate standard for ink-jet cartridge production lines and has implemented the system in its plants in the US and Singapore.

Bulk reprints of all Vision Systems Design

articles can be ordered from Sharon MacLeod, reprints manager, Vision Systems Design, at (603) 891-9224; FAX (603) 891-0574; or e-mail: [email protected].

Company Information

Allen-Bradley

1201 South Second Street

Milwaukee, WI 53204

(414)-382-2000

Fax: (414)-382-4444

Computer Identics/International Data Matrix

5 Shawmut Road

Canton, MA 02021

(617) 821-0835

Fax: (617) 828-8942

Domino Amjet

1290 Lakeside Dr.

Gurnee, IL 60031

(847) 244-2501

Fax: (847) 244-1421

Faxon Company

15 Southwest Park

Westwood, MA 02090

(617) 329-3350

Web: http://www.faxon.com

Hewlett-Packard

16399 West Bernardo Drive

San Diego, CA 92127

(619) 487-4100

Metanetics

43 Barkley Circle

Suite 102

Fort Meyers, FL 33907

(941) 939-4415

Fax: (941) 277-5317

Metrologic Instruments

Coles Road at Rte 42

Blackwood, NJ 08012

(609) 228-8100

Fax: (609) 228-6673

Symbol Technologies

One Symbol Place

Holtsville, NY 11742

(516) 738-2400

Fax: (516) 738-2831

UPS Research and Development

51-53 Kenosia Avenue

Danbury, CT 06810

(203) 731-6300

Fax: (203) 731-6340