Robots and vision: Vision system monitors stock levels for CNC tending robot

To optimize the dental crown milling process at Glidewell Laboratories (Newport Beach, CA, USA: www.glidewelldental.com), engineers have developed their own, low-cost, machine vision system in house. With the goal of improving production efficiency, the machine vision system was developed to monitor stock levels of 16 different shades of blanks that are used for machining the crowns and to detect dispenser jams while assisting a robot in tending four Computer Numerical Control (CNC) machines.

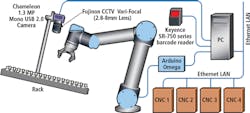

During operation, a UR5 robot from Universal Robots (Odense, Denmark; www.universal-robots.com) picks a crown to be milled from dispensers with partially-sintered blanks in 16 different shades. After picking the blank out of the dispenser, the robot presents it to a SR-750 series barcode reader from Keyence Corporation of America (Itasca, IL, USA; www.keyence.com) connected to a standard Windows PC cell controller.

The scanner reads a 2D matrix code that contains a shade indicator, a shrinkage factor and a serial number that is used to assign the specific patient information to the block serial number, and ensure that the crown goes to the correct patient.

If for some reason the shade indicated by the barcode is incorrect, the PC signals the UR5 robot through an Arduino Mega microcontroller board handling CNC cell I/O to reject the blank and place it on a conveyor. If the shade is correct, the robot proceeds to place the blank in the mill, where the system uses the shrinkage factor to enlarge the NC program just enough to ensure that the crown turns out the right size at the end of the process. After the 10-minute cycle, the robot takes the machined crown from the CNC and places it on a conveyor.

The machine vision system monitors the 16 different shades of blanks used for the machining the crowns. If a dispenser is empty or jammed, the operator is alerted to fix the issues. In the meantime, the UR5 is directed to carry out the next order in the queue to ensure continuous operation.

Glidewell engineer Babak Manafighazan developed the machine vision application and a user interface that allows operators to define separate regions around the blocks in the rack within the camera view on the monitor. To monitor for block presence, the software calculates and averages pixel contrast values for each area of interest, which represents one shade in the rack. During operation, the software continuously performs the same calculation as images are acquired and compares contrast values to the original saved values defined by the operator during setup. If there is a difference, the system notifies the operator that a block is jammed or not present.

"By notifying the operator to intervene or reload material when a particular shade is running low or has been exhausted," explains David Leeson, engineering director at Glidewell, "the vision system allows the robot to continue loading blanks for crowns that can be made with the remaining shades available to ensure continued production while waiting for the stock to be replenished."

To acquire the image of the dispenser rack with different shade blanks, the vision system relies on a Chameleon 1.3 MP monochrome USB 2.0 camera from FLIR Integrated Imaging Solutions (formerly Point Grey, Richmond, BC, Canada:; www.ptgrey.com). The camera has a Sony (Tokyo, Japan; www.sony.com) ICX445 global shutter CCD with a resolution of 1296 x 964, a 1/3" sensor format and a pixel size of 3.75 μm.

Paired with a model YV2.8X2.8LA-2 Vari-Focal (2.8-8mm) CCTV Lens from Fujinon (Wayne, NJ, USA; www.fujinoncctv.com), the camera achieves a field of view large enough for the final four blocks of each shade in each slot to be counted. After the digital image data is transferred to the PC via a standard USB 2.0 cable, the vision application analyzes the image to determine if any particular shade has four blanks or less remaining.

The machine vision system software programming is all home grown and written in C# using the Open Source Computer Vision Library (Open CV; http://opencv.org), according to Leeson. "Although it takes more work it dramatically reduces the cost over a turnkey solution and lets us use vision more liberally. This is a relatively simple vision system application for us so there weren't too many challenges. One thing we found necessary later was to change the material rack color by using black material instead of white to give us better contrast in a variety of lighting conditions."