Inspection system checks nasal-spray medication patterns

Spray-analysis imaging setup incorporates available hardware and customized software to characterize a concentrated pump spray pattern.

Drug stores and pharmacies carry a variety of nasal medications that are self-activated using a spray pump. Until recently, there was no reliable way to characterize the produced spray pattern. In the past, the analysis of the spray pattern has been a subjective and unreliable manual task.

But that's changing thanks to new software and an imaging inspection system developed by system integrator Atlantic Technologies Inc. (Deer Park, NY).

Valois of America (Norwalk, CT), a manufacturer of drug-delivery devices, is using application software and imaging apparatus from Atlantic Technologies that automates pump-spray inspection. In fact, this method may also establish an acceptable standard for both vendors and users of pharmaceutical spraying devices. No such standard is now available. The subjective nature of the manual methods in use often results in disagreements about what constitutes an acceptable pattern among those conducting tests at the pump spray manufacturing companies and the pharmaceutical companies using the devices.

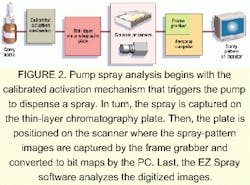

The imaging elements in the spray-inspection system include a scanner or TV camera, a frame grabber under PC control, and image-processing software; all these elements have been developed by Atlantic Technologies. The software may later become available as a commercial product under the name Valois EZ Spray. The test method, which uses a force-activation mechanism for the pumps, was developed by InnovaSystems (Pennsauken, NJ), and a test station was built by Valois (see Fig. 1).

Tim Olsen, senior systems engineer at Atlantic Technologies, designed the spray-pattern-analysis algorithm and the imaging system in use at Valois of America. The algorithm is based on DT Vision Foundry, an object-oriented software package for machine-vision applications developed by Data Translation Inc. (Marlboro, MA). Olsen was contracted by Valois to provide technical support in applying a precursor to DT Vision Foundry for evaluating the spray-diffusion-analysis challenge.

Valois initially employed Atlantic Technologies for a proof-of-principle task, for which Olsen developed the spray-diffusion algorithm that can be called as a custom tool on a PC toolbar. "Valois needed to analyze the pump's spray patterns the same way a human analyst does, and the software couldn't do that out of the box," Olsen says. But being able to create an application program such as EZ Spray "is the whole basis of the DT Vision Foundry software using the libraries included in the program," he adds. The DT program is divided into a main application and a set of imaging tools. The main application enables users to load, save, print, and modify images with the included tools.

Olsen used the tool-development feature of DT Vision Foundry to write a custom spray-analysis tool. He then developed this tool into a complete application program, along with the program's threshold, blob analysis, and morphology tools, which are included in DT Vision Foundry's library of vision and image-processing software.

The algorithm and custom tool are now undergoing validation tests at Valois of America. For the validation phase, Olsen converted the algorithm into a Windows NT-based application program—a move that could facilitate its acceptance as a standard spray-diffusion-analysis method that both pump and pharmaceutical manufacturers might accept.

System elements

The spray-analysis setup at Valois includes a CS-300 LE scanner from Polaroid Corp. (Cambridge, MA); a Data Translation Windows-NT-compatible DT3155 monochrome frame grabber that's also compatible with DT Vision Foundry; a generic 500-MHz Pentium III-based PC equipped with a variety of monitors; and Valois EZ Spray, the object-oriented image-processing application program that is written in C++ (see Fig. 2 on p. 26). Olsen says he has also successfully used an XC-75 CCD high-resolution (570 x 480-line) monochrome TV camera from Sony Electronics Inc. (Park Ridge, NJ) within the test setup in place of the Polaroid scanner.

The software program determines the border of the concentrated spray pattern, and it also measures the minimum and maximum distances across the spray pattern through its center of gravity. "The program determines if the axis of the center of the spray pump is within the region determined [as acceptable] by the algorithm, and that's one of the go/no-go tests used to assess the nozzle," Olsen explains.

"But learning how to find where the end of the spray concentration is located, which is the same problem a human analyst has, was a challenge," he says. "We established a binary factor that sets a hook that both the nozzle vendor and customer can use to move the edge of the boundary in and out to obtain a quantified measure of the edge of the pattern. That was one of our most difficult challenges."

Guillaume Brouet, research laboratory manager at Valois, says validation tests made last month were successful using sample pumps, and he's drafted a validation protocol to be used at the headquarters of parent company Pharmaceuticals of Valois in Normandy (Le Vaudreuil, France). He adds that the biggest challenge in developing the algorithm and test method was to "come up with a discipline that improves on manual calculations and mimics them by assessing the [spray] patterns the same way an analyst would, but removes the subjectivity." Brouet says the research laboratory team worked with Olsen "to initially make the algorithm flexible enough to calculate patterns the way we do and then freeze a set of parameters for routine control." At the same time, the procedure has to satisfy the concerns of the US Food and Drug Administration (FDA) about the quality and consistency of nasal spray diffusion.

Color me blue

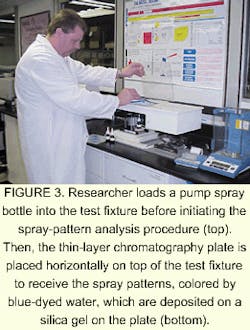

To see the spray pattern, Valois adds a blue-colored water agent for the tests as the pump is activated to dispense a preset amount onto a thin-layer chromatography (TLC) plate measuring 20 x 20 cm (see Fig. 3 on p. 27). After spraying, the blue dye is fixed in place by the silica gel of the plate. Next, the plate is scanned and the patterns are converted to a bit-map file to be analyzed by the PC software—the EZ Spray program.

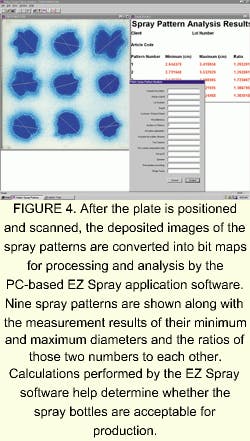

The program calculates the center of gravity of the spray pattern, plus the longest and shortest diameters of the pattern, along with the ratio of those two diameters to each other—all of which previously had to be done manually by an analyst (see Fig. 4). The EZ Spray program can test nine nozzles at a time in milliseconds instead of the one-at-a-time limit associated with manual analysis, "but we still need another few seconds to feed and prime the nozzles," Brouet points out.

"It's difficult to determine the center of a pattern manually," he explains. "It's also tough to define the edge of the spray pattern, but the algorithm performs the calculations the same way each time, which was a major challenge." That consistency is also a key advantage of using the software instead of manual calculation, as is the program's ability to locate the center of gravity of the pattern, Brouet stresses.

He notes that Valois of America hopes the promising results obtained by the EZ Spray procedure and apparatus will comply with draft guidelines for nasal sprays established last year by the FDA.

Company Information

Atlantic Technologies Inc.

Deer Park, NY 11729

Web: www.atlanticvisionsystems.com

Data Translation Inc.

Marlboro, MA 01752

Web: www.datatranslation.com

InnovaSystems Inc.

Pennsauken, NJ 08109

Web: www.innovasystems.com

Polaroid Corp.

Cambridge, MA 02139

Web: www.polaroid.com

Sony Electronics Inc.

Park Ridge, NJ 07656

Web: www.sony.com/professional

Valois of America

Norwalk, CT 06851

Web: www.valois.com