IR technology finds machine-vision niches

Different types of infrared cameras are in use in specialized machine-vision applications.

By Andrew Wilson, Editor

Says Thomas Scanlon, vice president of FLIR Systems, “When it comes to machine vision, many people only think of imaging objects in the visible spectrum. Those who do consider infrared (IR) inspection as a solution are often dissuaded from using the technology due to the price of IR cameras. But, in some machine-vision applications,” he argues, “the need for sophisticated lighting and lighting-control systems can be radically reduced, making IR technology competitive with visible-light-based systems.”

Gary Orlove, manager of FLIR’s Infrared Training Center, is only too aware of the problems facing those who consider using infrared technology. “Many times,” he says, “customers will call describing a specific problem and ask whether it can be solved using IR imaging. In 98% of cases, these applications are not related to a specific wavelength and can be solved using a microbolometer-based system that operates across the 7.5-13-μm spectrum.”

Such applications include industrial inspection of furnaces and electrical and petrochemical plants. In these applications, thermal detectors such as microbolometers with broad, uniform spectral responses can be used. Orlove notes, “Although the devices have lower sensitivities and slower response times than photodetectors, they can be operated uncooled and are relatively inexpensive.”

SPECTRAL CHARACTERISTICS

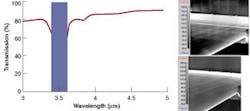

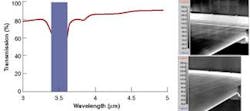

To properly understand whether a specific machine-vision task can be solved using IR technology it is necessary to understand the spectral characteristics of the material to be examined. To accomplish this, a spectral scan of the object must be made with an IR spectrometer or a spectral radiometer. Infrared spectrometers allow transmission-vs.-wavelength plots to be determined for the specific material (see Fig. 1). Regions where the camera will see though the material are shown as peaks. Valleys are wavelength regions with higher absorption where the camera will not see though the material.

“Typically,” says Paul Czerepuszko, business-development manager at FLIR, “an overall transmission of 80% or greater is needed to see through the material, while 20% or less is needed to inspect the surface.” To isolate this region of interest, IR filters can be matched to the spectral response to isolate specific parts of the spectrum. In this way, IR cameras can be tailored to inspect the characteristics of a number of different materials.

“One of the most important factors in choosing an IR camera for machine vision,” says Czerepuszko, “is making sure that the camera’s spectral region matches that of the object under test.” Although filters can isolate specific regions of the spectrum, they can also reduce sensitivity or quantum efficiency of the system.

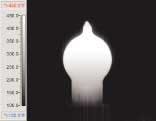

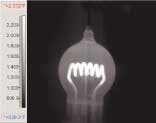

FLIR Systems has demonstrated several wavelength-specific vision applications that include the measurement of glass, thin-film plastics, and transparent gases. In each of the applications, a specific wavelength is isolated before measurements are taken (see Fig. 2). “Because glass is semitransparent to IR in the short-wavelength region and reflective in the long-wavelength region, using a 5-μm filter will provide minimal transmission and reflectivity,” says Czerepuszko. When used with an IR camera, such filters allow the surface temperature of glass bulbs to be measured. To visualize the filament within the bulb, a narrow-bandwidth filter below 4 μm provides maximum transmission and minimum reflectivity.

In measuring thin-film plastics, the spectral characteristics show that for the majority of the IR region, the material is transparent. To allow the measurement of the surface of the plastic rather than the web equipment behind it, a narrow-bandwidth filter centered at 3.4 μm is used. Like thin-film plastics, transparent gases are also transparent throughout the IR region. “Carbon dioxide, for example,” says Czerepuszko, “is a nonhazardous gas that can be imaged using a 4.3-μm filter. In such applications, even very small amounts of gas can be seen against a warm background,” he adds.

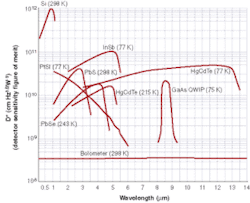

“Currently,” says FLIR’s Scanlon, “many commercially available IR cameras use uncooled focal-plane arrays (FPAs) based on bolometric or ferroelectric devices. For special applications, where high-speed, improved sensitivity or spectral selectivity is required, cooled photodetector arrays are used. These include indium antinomide (InSb), mercury cadmium telluride (MCT or HgCdTe), and QWIP (quantum-well infrared photodetector) devices.” These devices exhibit different spectral-response curves and detector sensitivities (see Fig. 3).

Chris Alicandro, director of sales at Electrophysics, agrees. “Traditionally,” he says, “the IR camera market has been dominated by bolometer-based products. Many applications, however, demand higher speeds and spectral sensitivity, and in these applications sensor-specific cameras provide the most-effective way to image specific products. “Bolometer-based cameras are frequency-independent thermal sensors that detect the temperature of a scene, while photonic detectors are tuned for specific IR wavelengths,” he says.

Although bolometer-based cameras are generally lower cost, frame rates are limited to the time constant of the bolometer itself, resulting in typical maximum clocking speeds of 60 frames/s. “Because photonic devices are not limited in this manner,” he says, “they can be clocked much faster. Indeed, InSb-, QWIP-, or MCT-based cameras can be clocked at hundreds of frames per second.”

SENSOR TECHNOLOGIES

Many companies offer sensors fabricated with different technologies (see table on p. 77). Sensors built using these technologies have been incorporated into camera systems to meet specific imaging applications. For example, Indigo Systems, now FLIR Indigo Operations, recently announced a new method for processing indium gallium arsenide (InGaAs) to enhance its short-wavelength response. The new material, VisGaAs, is a broad-spectrum substance that enables both near-IR and visible imaging on the same photodetector (see Vision Systems Design, December 2003, p. 35). This VisGaAs sensor is now available in FLIR’s Alpha NIR camera. The company’s standard Alpha NIR camera head uses a 320 × 256, InGaAs-based FPA with a spectral-sensitivity range from 900 to 1700 nm.

Although FLIR is the only company to offer such a visible/IR hybrid camera, many vendors also offer InGaAs-based cameras. Sensors Unlimited, for example, uses its SU320M detector in its own camera. With sensitivity in the near-IR spectrum (900-1700 nm), the camera is targeted at laser-beam profiling and semiconductor inspection. With RS-170- or CCIR-compatible output, captured images can be viewed on standard broadcast monitors.

“Although InGaAs-based cameras offer high sensitivity,” says Alicandro, “they feature a relatively narrow spectral response. This makes them useful in applications such as spectroscopy, microscopy, and night vision.” To increase sensitivity at longer wavelengths (750 nm to 2.5 µm), TE-cooled MCT-based cameras are generally preferred in applications such as chemical spectroscopy/analysis, hyperspectral imaging, remote sensing, and certain laser applications. The MCT material is more expensive to produce than InSb, but it can be optimized for short-, medium-, or long-wavelength applications or a combination of wavelengths.

For these applications, Electrophysics supplies its Jade and Emerald series of cameras (see Fig. 4). Developed by CEDIP Infrared Systems, the cameras use detectors from Sofradir to offer an IR image at full TV-size format. Emerald uses InSb or MCT FPAs of 640 × 512 pixels operating in snapshot mode. Emerald and Jade MWIR cameras operate in the 3-5-µm wavelength range and offer a typical noise-equivalent temperature difference (NETD) as low as 18 mK. Designed for multiple applications, including airborne imaging or long-range surveillance, the cameras use CEDIP’s Cassiopea electronic readout modules. The Emerald and Jade cameras can be controlled from a host PC through a communication port and exposure time and external synchronization modes programmed using PC-based software.

QUANTUM WELLS

Because perfecting IR devices based around MCT devices is expensive, cameras built using such devices can cost as much as $65,000. This is primarily because MCT material is more difficult to grow than other materials. As an alternative, QWIPs are now being offered by several companies to address long-wavelength IR applications (see Vision Systems Design, Sept. 2004, p. 10).

Despite their increased spectral sensitivity across the 8-9-μm spectrum, the quantum efficiency of QWIPs is less than their MCT-based counterparts. “Typically cryogenically cooled to 66 K, QWIPs exhibit a quantum efficiency (QE) of approximately 30% compared with a QE of greater than 80% for MCT-based cameras,” says Alicandro. The benefit, however, is reduced cost.

For a number of years, FLIR has offered mainly microbolometer-based cameras (see Vision Systems Design, September 2004, “Worldwide Industrial Camera Directory”). The company does offer one QWIP-based camera, however-the ThermaCAM SC3000. Interestingly, since FLIR’s acquisition of Indigo Systems, the company offers two very similar products based on QWIP technology-the FLIR Thermacam 3000 and the Indigo (FLIR) Phoenix Long.

THERMAL IMAGING

Uncooled microbolometers are available from many vendors, but their spectral sensitivity is much lower than all other types of IR detectors. Indeed, the NETD of the Ulis UL01021E is 160 mK, compared with 25 mK for MCT-based devices. Because microbolometer devices operate across the 7-14-μm spectrum, however, they are well suited to industrial thermal-measurement applications such as plant inspection.

The DI-9800e from Digital Imaging Infrared is a good example of a microbolometer-based camera. Capable of detecting passive radiation in the 8-12-μm spectral band, the camera uses a vanadium oxide (VOx) 320 × 240 detector that can be supplied in a number formats from 25 to 51 μm square. With RS-170 or CCIR output, the DI-9800e features <85 mK NETD and automatic or manual focus.

While today’s IR market continues to be dominated by microbolometer-based cameras, the wide range of IR cameras available allows systems developers to deploy a variety of sensor technologies to meet applications that may require more sensitive measurements at specific frequencies. In machine-vision applications, the knowledge of the spectral characteristics of specific objects or materials to be tested is an important factor in determining the type of IR system to be used. And, although such cameras remain more expensive than their visible counterparts, how these cameras are to be used should be considered, especially in systems where otherwise sophisticated lighting and lighting-control systems may need to be deployed.

Company Info

AIM Infrarot-Module, Heilbronn, Germany www.aim-ir.com

CEDIP Infrared Systems, Croissy-Beaubourg, France www.cedip-infrared.com

Digital Imaging Infrared, Apopka, FL, USA www.dii-llc.com

Eastman Kodak, Rochester, NY, USA www.kodak.com

Electrophysics, Fairfield, NJ, USA www.electrophysics.com

FLIR Systems, North Billerica, MA, USA www.flir.com

QWIP Technologies, Altadena, CA, USA www.qwip.com

Raytheon Commercial Infrared, Dallas, TX, USA www.raytheoninfrared.com

Sensors Unlimited, Princeton, NJ, USA www.sensorsinc.com

Sofradir, Paris, France www.sofradir.com

Ulis, Veurey-Voroize, France www.ulis-ir.com