Camera Link extenders aid in timber inspection

In the production of sawn timber, manufacturers must be able to grade specific classes of wood based on their material properties. These grading criteria include whether the timber has knots, resin pockets, or different types of faults in its shape or structure. To do this grading automatically, Lisker Oy (Vaaksy, Finland; www.lisker.fi) has developed a grading system for sawn timber, known as ProfiGrade, that is suitable for both dried and undried timber.

"ProfiGrade is designed to categorize sawn timber into different grades that are sold with different prices," says Kaarlo Kerkkänen, president of Lisker Oy. "Certain cheaper grades will have more knots and other defects and can be separated from more valuable grades after inspection."

Typical throughput of the system is two pieces per second on a transverse conveyor, with pieces being approximately 6 m long. For green sawn timber, ProfiGrade mostly controls trimming, and for dry timber it puts different grades into different pockets (so-called final grading).

null

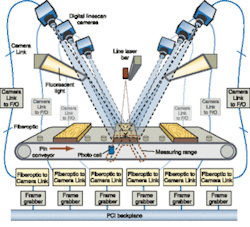

According to Kerkkänen, typical systems cost from 150,000 to 250,000 euros per station, depending on system specification. The base system consists of four linescan cameras, fluorescent lamps, a semiconductor laser bar, absolute encoder, and multiprocessor computer. This combination allows the system to grade both edges and the upper face of the wood.

In the sawn-timber grading system, a laser line bar illuminates and thus highlights the 3-D shape of a piece of timber as it passes under three parallel L300 Series trilinear color linescan cameras from Basler Vision Components (Ahrensburg, Germany; www.baslerweb.com) and forms a 6-m-long line that is along the longitudinal axis of sawn pieces, running on a transverse conveyor. "Two stations of three cameras are needed to inspect the pieces from both sides," says Kerkkänen. "Camera optics and lengthwise accuracy are the main reasons for having three cameras instead of one."

One of the key obstacles in the design of the system was overcoming the harsh environment of the sorting machinery. It was necessary to distance the cameras from the frame grabbers and host PCs used at distances of greater than 10 meters.

To accomplish this, Lisker Oy interfaced each of the cameras with a Camera Fiber-Link extender from Logical Solutions (Milford, CT, USA; www.thinklogical.com). After digital Camera Link data are transferred over the fiber, they are reformatted to the Camera Link standard and digitized by a Meteor II frame grabber from Matrox (Dorval, QC, Canada; www.matrox.com/imaging). To digitize data from all six cameras, three pairs of extenders are used and individually interfaced to six Meteor II frame grabbers in an industrial PC.

"At the moment there is one dedicated frame grabber for each camera, but we will redesign the system in the near future so that each frame grabber is capable of handling two cameras," says Kerkkänen. To capture the image data, Lisker Oy used Matrox's MIL with specialized image-analysis algorithms developed in C++ language. To trigger image capture, a photocell located under the conveyor is interfaced to the frame grabbers. The diagonal positioning of the line lasers and cameras then makes it possible to calculate a 3-D model of the measured board or stud.

From this model the grading program determines dimensions; the amount of bow, spring, and twist; and other factors. To control the sorting and trimming of the wood, the ProfiGrade system can be connected to PLCs via RS-232, RS-422, or with a TCP network protocol.