Imaging system explores harsh industrial environments

High temperatures (up to 500°C), high vacuum, or hazardous atmospheres are often encountered in locations such as chemical refineries, incinerators, sterilization procedures, and power-production facilities. A machine-vision system that can be deployed in such harsh environments allows process operators to view, record, and analyze real-time changes taking place and make any adjustments required.

"Because such environments are so harsh," says Michael Pollack, general manager of Greene, Tweed Technologies (Hatfield, PA, USA; www.gtweed.com), existing imaging systems must be customized to withstand high temperatures, harsh chemicals, and radiation." In the development of machine-vision systems for such environments, Greene, Tweed Technologies has drawn on its 25-year experience as a government supplier of chemically inert electrical and microwave feedthrough devices. Using a conductor joined to high-purity aluminum oxide brazed to a metal body, these devices are incorporated into products such as lithium batteries, where electrical power must be transferred from a harsh environment to an outside device.

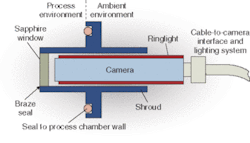

When developing its imaging system to inspect and analyze hazardous processes, Greene, Tweed Technologies realized that any system would have to be isolated from the environment. Based on technologies for joining synthetic sapphire (single crystal of aluminum oxide), the company has developed a number of borescope-like protective shrouds, some with gas-cooling capabilities, that allow imaging systems to be deployed directly into the chemical or process reaction.

"In the design of the shroud," says Pollack, "a transparent optical window made of synthetic sapphire is brazed with specially developed, chemically inert, and mechanically durable alloys to the front of a tube made from Hastelloy C (a chemically inert replacement for 316 stainless steel)." Depending on the application, the diameter of the synthetic sapphire window can range from 1/8 to 3 in. "Synthetic sapphire is the preferred option for such shroud windows," says Pollack, "since it is nearly as hard as diamond, chemically resistant, and has excellent light transmission characteristics."

The company modified a 3/8-in.-diameter commercially available lipstick camera to fit within a 1-in.-diameter shroud, the format most often used in harsh industrial applications. "It was also necessary for the camera module to illuminate the chemical or nuclear process being monitored," says Pollack. This was done by incorporating a ring of optical fibers around the solid-state imager and enclosing the fiber-imager combination within the camera module.

Using an off-the-shelf light source from Welch-Allyn Lighting Products (Skaneateles Falls, NY, USA; www.walamp.com), cold white light can be delivered through the shroud window, while the external camera interface remains distant from the shroud/camera head combination. S-Video output can then be displayed from the camera module on an external flat-panel monitor.

"Although the current system uses specific types of cameras and illumination equipment," says Pollack, "it can be easily modified to incorporate many different imaging formats and digital interfaces. Various types of imagers, at speeds from 29.97 up to 10,000 frames/s, are available. Since the image output is standards-based, captured images can be easily processed with off-the-shelf image-processing packages such as IMAQ Vision from National Instruments (Austin, TX, USA; www.ni.com).

The camera/shroud, illumination source, and video display are available in the Model 1100 Series, a suitcase unit that includes all of these components. The company hopes to show how such imaging systems can be effectively deployed in harsh environments. Currently, customers include petrochemical companies qualifying the efficiency of hydrogen-generating palladium catalysts and incinerator applications that determine the effectiveness of burning hazardous wastes.