UNTERSCHLEIßHEIM, GERMANY—Landslides are a common geological hazard in mountainous areas. Large boulders carried by debris flow can be highly destructive to roads, buildings, and even to passing vehicles. Constructing steel baffle on steep slopes is a proven method to dissipate the impact energy of boulders and a cost-effective alternative to larger reinforced concrete structures. However, current designs of steel baffle, and its footings and structural connections, may impede the effectiveness of baffle as a safety measure.

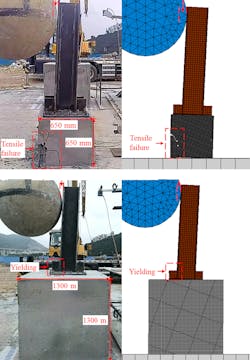

Researchers at the Hong Kong University of Science and Technology1 have conducted full-scale pendulum impact tests on new baffle designs. A baffle was installed on cubic footings with side lengths of either 650 mm (2.13 feet) or 1300 mm (4.25 feet), with and without steel dowels set at different depths in the earth. To conduct the testing, concrete boulders weighing nearly 4500 pounds were hoisted by cranes and released downhill on the baffles, exerting impact energy up to 100 kilojoules.

To capture the impact process of boulders on the various baffle designs, a Mikrotron MotionBLITZ mini GigE Vision monochrome camera was placed at one side of a large test platform. Camera resolution was set for 1280 × 1008 pixels at 300 frames per second, resulting in analysis-quality images thanks, in part, to its high-speed global shutter. Laser sensors mounted on the baffles' top and bottom measured deflection. The camera, laser sensors, and other instrumentation, including an accelerometer and strain gauges, were connected to a data logger. Multi-physics software was applied to create 3D finite element models based on the collected data. Next, the 3D models were uploaded to carry out a parametric study to investigate the different configurations when subjected to different impact energy levels depending on how far uphill the boulders were released.

The researchers found that a footing with a side length of 1300 mm connected to the ground by eight steel dowels was required to avoid failure of the cubic footing during high impact, and that the dowels in the soil should be installed at least 4500 mm (14.75 feet) to avoid overturning the structure. Results presented in the study will now be used by safety engineers in designing baffles to strengthen the resilience of mountainous areas.

For more information on Mikrotron cameras, visit www.mikrotron.de.

- "Analysis of steel baffle installed on footing with dowels for resisting boulder impact," Charles W.W.Ng, Dingchen Zhang, Clarence E.Choi, Haiming Liu, Raymond C.H.Koo, Rui Chen, Engineering Geology Volume 312, January 2023