Processors embed programmable logic

In many smart-camera and image-processing boards, developers combine the power of general-purpose-processor (GPP) or DSP-based systems with programmable logic. Now, Stretch (Mountain View, CA, USA; www.stretchinc.com) has combined the two approaches in a single family of devices known as the S5000 series. By embedding programmable logic inside a software-programmable processor, system designers can extend the processor instruction set itself, not just add complementary external logic nearby. Combining software programmability and programmable logic by embedding the logic inside the processor architecture allows logic to be programmed with conventional software.

The Stretch S5000 software-configurable processors are based on the Stretch S5 engine, which incorporates the Xtensa V RISC processor core from Tensilica (Santa Clara, CA, USA; www.tensilica.com) and Stretch Instruction Set Extension Fabric (ISEF). The ISEF is a software-configurable datapath based on proprietary programmable logic. The FPGA-like ISEF logic is designed for implementing variable-sized ALUs, multipliers, and shifters as datapath extensions to the processor. The ISEF computes complex functions in parallel similar to an FPGA but that can be tailored by system designers for compute-intensive applications.

Using the ISEF, system designers extend the processor instruction set and define the new instructions using C/C++ code. Since the ISEF is reloadable during operation, a small ISEF area can support a number of instructions resulting in greater efficiency than an FPGA-based design. Stretch has shown that the S5000 processors can exceed the performance of GPPs, DSPs, ASPs, and FPGAs.

According to company benchmarks, a 300-MHz Stretch S5610 processor tailored for DSP outperforms all other processors including the 2-GHz FastMATH processor from Intrinsity (Austin, TX, USA; www.intrinsity.com), the 720-MHz C64 processor from Texas Instruments (Dallas, TX, USA; www.ti.com), and the 1.3-GHz PowerPC with Altivec processor from Motorola (Austin, TX, USA; www.motorola.com).

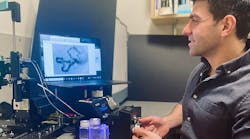

System checks ink drops

Designers and manufacturers of print heads must often characterize both their prototype and final designs. To do this, drop-formation time, drop size, velocity, and flight time of the ink to the substrate must all be accurately measured. Imaging Technology international (iTi; Boulder, CO, USA; imagingtechnology-corp.com) has developed the Drop Watcher III, an integrated system that provides automated, repeatable measurements of ink-jet drop formation and flight characteristics from a range of print heads. Says Ross Mills, chief technologist and founder of iTi, “The Drop Watcher III system incorporates an x-y motion-control subsystem that automatically moves a camera-based microscope across all the nozzles in a print head.” Typically, each print head accommodates between 128 and 1024 nozzles per head. In this way, the system is able to characterize the jetting properties of the print head.

The system also includes a mechanical stage that controls the print-head roll, yaw, and pitch relative to the focal point of the camera. Both strobe delay and pulsewidth are user-adjustable for viewing and measuring various stages of the fluid’s drop formation.

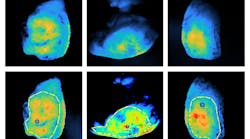

NEDs shown at SID

At the recent Society for Information Display (SID) International Symposium, Seminar and Exhibition (Boston, MA, USA; May 22-27), Motorola Labs (Austin, TX, USA; www.motorola.com/labs), the applied-research arm of Motorola, announced a 5-in. color video-display prototype based on carbon nanotube technology (CNT). This could create large, flat-panel displays with superior quality, longer lifetimes, and lower costs. Less than 1 in. thick, the nano-emissive display (NED) prototype is based on a scalable method of growing CNTs directly on glass to enable an energy-efficient way of emitting electrons. “With more than 160 patents in CNT and flat-panel displays, we are looking forward to aligning with display manufacturers and enabling them to further this technology and develop commercially available solutions,” said Jim O’Connor, vice president, Motorola technology incubation and commercialization.

“Motorola’s NED technology is demonstrating full-color video with good response time,” said Barry Young, vice president and CFO of DisplaySearch (Austin, TX, USA; www.displaysearch.com). “According to a cost-model analysis conducted by DisplaySearch, we estimate that the manufactured cost for a 40-in. NED panel could be less than $400.”

“Motorola has proven its NED technology to be fully video capable,” said Kimberly Allen, director of display technology and strategy for analyst firm iSuppli (El Segundo, CA, USA; www.isuppli.com). “CNT direct growth on glass appears to have advantages over CNT paste/printing approaches and has potential for larger and more sophisticated displays.” The prototype is formatted as a 5-in. section of a 42-in., 1280 × 720-pixel, 16:9 HDTV display. Panel thickness is 3.3 mm, and drive electronics are similar to that used for LCDs.

FireWire attacks industrial-automation apps

Fraunhofer IPMS (Dresden, Germany; www.ipms.fraunhofer.de) is developing a FireWire standard that allows the combination of motion, vision, and I/O on one bus. Designed for factory-automation and industrial-automation applications, the 1394AP (automation protocol) standard consists of an application layer that comprises a bus management, asynchronous transfer, and isochronous transfer interface that are used to control management, transaction, and link layer services.

To prove the concept, Fraunhofer will develop an embedded system using a C161 16-bit microcontroller from Infineon Technologies (Munich; Germany; www.infineon.com) that will run the 1394AP software stacks. Founded in 2002, the 1394Automation group is composed of several European companies including Basler Vision Technologies (Ahrensburg, Germany; www.baslerweb.com), Maxon Motor (Sachseln, Switzerland; www.maxonmotor.com), and Nyquist Industrial Control (Eindhoven, The Netherlands; www.nyquist.com). Their objective has been to enable diverse industrial systems and automation products from different manufacturers to operate together using FireWire.

Late last year, the 1394Automation Group merged with the 1394 Trade Association (www.1394ta.org) for coordinated development, marketing, and application development. Contact Michael Scholles (e-mail: [email protected]) for more information.