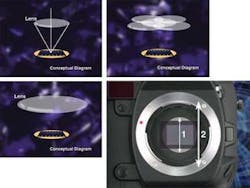

By incorporating smart controllers into lenses, autofocus and aperture can be electronically controlled.

By Andrew Wilson, Editor

For years, OEM suppliers to the machine-vision industry have leveraged consumer, computer, and broadcast technologies to lower the cost of their products. While frame-grabber vendors have used broadcast-compatible standards and devices, smart-camera vendors have used computer-network standards such as Ethernet, USB, and FireWire in their designs. Now, camera vendors are looking to incorporate smart lenses into their products to increase functionality.

In designing the company’s electronic-focus (E-F) lenses, Canon engineers have developed an interface standard that allows Canon camera bodies (such as the 16.7-Mpixel EOS 1Ds Mark II) to electronically control functions such as autofocus and aperture. According to Canon, this electronic mount system has none of the abrasion, play, slow response, and diminished precision caused by lever operation. Furthermore, the lens’ built-in microcomputer can even warn of malfunctions through the camera’s LCD readout.

To date, Canon offers numerous types of lenses that support the E-F standard (see Fig. 1). And, because these are generally targeted at consumer applications, they can be purchased from camera and lens suppliers such as Ritz Camera and B&H Photo Video.

Tear it apart

Olle Bjernulf of Uppsala, Sweden (www.geocities.com/Yosemite/8917/index.html) and Steve Weixel of Photoscene (www.photoscene.com/sw/tour/inside.htm) have disassembled the Canon EF 75-300/4-5.6 and F-28-105 USM lenses, respectively, to better understand their intricate design. They found that the Canon E-F lenses use deformation stepper motors to control the aperture blades with a series of electronic pulses.

“Other than the initial signal, control over the aperture is handled entirely within the lens,” says Weixel. Canon also has incorporated an ultrasonic motor that acts as the focus-drive component. When a piezoelectric element in the lens extends and contracts in response to voltage, its oscillation is converted into rotary movements that allow free control of the angle rotation and operation at low speeds.

“Unfortunately,” says Jim Strutz of PhotoNotes.org, a web site created by Tela Design, “Canon is unwilling to license its protocols to third-party manufacturers.” Because of this, a number of lens, lens-controller, and camera manufacturers have reverse-engineered the standard and incorporated it into their own products. “Sigma Corporation is known for its third-party lenses, which rely on reverse-engineering of Canon’s lens-mount protocols. Tamron and Tokina are two other manufacturers that sell third-party lenses, all likely reverse-engineered,” he says.

“But there is a drawback to reverse-engineering. Sigma may indeed figure out how its products can work flawlessly with Canon products, but Canon can alter its future products in such a fashion that older third-party items no longer function correctly,” says Strutz. “This happened most recently with the introduction of the Canon EOS Elan 7/30/33/7, a camera body that does not work with certain older Sigma lenses.”

Benefits in reverse

Despite the potential drawbacks to reverse-engineered third-party products, the benefits of using a computerized lens with electronic aperture and autofocus is very appealing to system integrators. Because of this, a number of image-processing and machine-vision companies, including Birger Engineering and Imaginant, have “adopted” the standard in both lens-controller and digital-camera products.

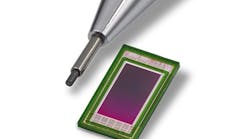

According to Erik Widding, Birger Engineering president, his company’s products are already in use at dozens of OEMs worldwide. Its EF232 adapter lets system integrators use and control Canon E-F-mount lenses without the use of a Canon EOS camera body (see Fig. 2). With the adapter, focus and iris functions are precisely controlled over an RS-232 serial port. “The beauty of the Canon EOS lens system is that all of the actuators for the lens are incorporated,” says Widding. “But the difficulty has been that many of the Canon lenses could not even be manually focused without being attached to a Canon EOS camera body. By taking the place of the camera body, the EF232 adapter provides repeatable focus and iris control in half-stop increments.

The electrical and logical interface to the lens is handled by the adapter. Programmers control the adapter through a set of intuitive two-character commands to a computer with a standard RS-232 serial port and a 6V/1A dc power supply. Birger Engineering offers a mechanical adapter that mounts the EF232 to any standard C-mount camera. “The EF232 adapter has a back focal length of 1.1 in., but cameras with greater back focal lengths that use thermoelectric coolers and/or shutters can be accommodated.” At present, the company is also testing a version of the adapter that incorporates a CS45 shutter from Vincent Associates, drive electronics for the shutter, and the EF232 in a 4.25-in.-diameter single package with a back focal length of 0.9 in.

Having a 45-mm aperture and a 14-ms opening time, the CS-45 is supplied in a 4.00-in.-diameter housing and incorporates a miniaturized actuator system that is driven with the company’s VMM drive units. Using the shutter with the EF232 lens controller thus allows shutter speed, focus, and iris functions of the digital-camera system to be controlled electronically. As an option, the shutter can be equipped with a synchronization system that is electronically programmed to fire specific exposures at precise time intervals.

Lens standards

“When the EF232 adapter was introduced, image sensors were generally quite small, so a majority of applications were well served by C-mount optics,” says Widding. “In the past year, however, we have seen increased interest in the product due to the availability of relatively inexpensive large-format sensors. These sensors, coupled with single-lens-reflex (SLR) camera lenses, offer a very economical solution. The Canon E-F and Sigma SA lenses, as well as various manufacturers’ lenses incorporating the Four Thirds System Standard (www.four-thirds.org), have a completely electrical interface for iris and focus.

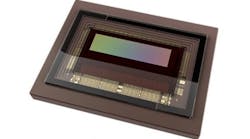

The Four Thirds System, for example, defines a standard for the design and development of digital SLR camera systems that use a Four-Thirds-System-type image sensor. In addition, the system defines an open standard for lens mounts that assures compatibility between Four Thirds System bodies and lenses produced by different manufacturers (see Fig. 3). Originally announced in September 2002 by Olympus and Eastman Kodak, the Four Thirds System standard has been supported since its inception by Fuji Photo Film.

“We selected the Canon E-F lens platform for our first product, as we were initially looking for a lens platform that would be well suited to automation,” says Widding. “For quite a different reason-the ease of use of an all-mechanical interface-the vision industry had standardized on Nikon F lenses. Though initially easy to use, many of the newest F lenses from Nikon no longer have aperture rings, so an electronic interface to the lens is required to determine the current aperture. These lenses are becoming more interesting from an automation perspective, as many of them can be focused electronically,” he says.

Birger Engineering’s next adapter release will include support for USB, image stabilization, a field-upgradeable protocol, and EF-S lenses. The company is also at work on products that support other SLR camera-lens platforms that are both mechanically and software compatible with the existing product. According to Widding, these will be available at the end of 2005.

Gigabit Ethernet

Robert Hibbard, vice president of imaging at digital-camera-vendor Imaginant, also understands the benefits of supporting the Canon E-F lens mount. At present, the company offers two high-resolution Gigabit Ethernet-compatible cameras targeted toward the scientific and microscopy markets. Featuring a 4032 × 2686-pixel KAI-11000 interline-transfer progressive-scan CCD from Kodak, the HR-1100c digital camera can capture and process one full frame every 5.5 s. For faster image capture, the company’s HR-200c digital camera uses the Kodak KAI-200 CCD with 1608 × 1206-pixel resolution that can capture and process color images once every 1.2 s. The rates of frame capture into internal memory for both cameras are even greater.

“What makes both cameras unique is not just their resolution,” says Hibbard. Indeed, companies such as Redlake and Imperx offer competitive products. By reverse-engineering the Canon E-F specification and incorporating the electrical design into the body of the camera, all Canon E-F lenses can be used with the camera. “Thus,” says Hibbard, “in addition to controlling the burst capture, trigger, and strobe rates of the camera, both the focus and aperture of the lens can be adjusted automatically over the Gigabit Ethernet interface. According to Hibbard, this is the first time a third-party camera developed for nonconsumer applications has supported the E-F lens interface. “Our camera’s field-upgradable firmware allows updates to the camera’s features and also supports future needs, such as new lenses or protocols, as they are released,” adds Hibbard.

With a single-unit list price of $9495 for the HR-200c and $13,995 for the HR-1100c, Imaginant’s cameras are not inexpensive. But incorporating an on-board processor, the E-F specification, a Gigabit Ethernet interface, and a software-development kit that controls multiple camera functions eases the task of developing systems that require automated camera control. In this way, system integrators will be able to increase the degree of automation of both their imaging system and the applications in which they are being deployed.

To offer similar functionality for its range of cameras, Redlake has chosen to adapt Birger’s EF232 mounts to several of its industrial-camera models. According to Jay Kelbley, product marketing manager at Redlake, Canon’s EOS lenses are ideally matched to the ES11000, a camera that uses a full 35-mm, 11-M- pixel Kodak sensor. “The primary value of the EF232-enabled cameras is the ability to control aperture and focus remotely,” says Kelbley. “On a larger-format camera such as the MegaPlus II ES11000, this creates an efficient machine-vision solution. Many of Canon’s fast AF lenses are unique. Its 85-mm, f/1.2 lens, for example, is very useful in applications that require low light or extremely low depth of field. Canon’s lineup of three Tilt Shift lenses also allows system integrators to obtain a wide depth of field, even at maximum aperture.”

Company Info

B&H Photo Video

New York, NY, USA

www.bhphotovideo.com

Birger Engineering

Boston, MA, USA

www.birger.com

Canon

Lake Success, NY, USA

www.usa.canon.com

Eastman Kodak

Rochester, NY, USA

www.kodak.com

Fuji Photo Film

Valhalla, NY, USA

www.fujifilm.com

Imaginant

Pittsford, NY, USA

www.imaginant.com

Imperx

Boca Raton, FL, USA

www.imperx.com

Olympus

Melville, NY, USA

www.olympusamerica.com

Nikon

Melville, NY, USA

www.nikonusa.com

Redlake

San Diego, CA, USA

www.redlake.com

Ritz Camera

Irvine, CA, USA

www.ritzcamera.com

Sigma Corporation

Ronkonkoma, NY, USA

www.sigma-photo.co.jp

Tamron

Commack, NY

www.tamron.com

Tokina

Saitama, Japan

www.tokina-usa.com

Vincent Associates

Rochester, NY, USA

www.uniblitz.com