Andrew Wilson, Editor, [email protected]

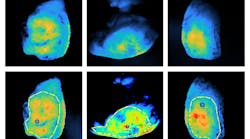

In microscopy, astronomy, and many medical-imaging applications, very-high-resolution images must be acquired, mandating the use of full-frame-transfer-based cameras. These frame-transfer cameras, manufactured by companies such as Atmel (San Jose, CA, USA; www.atmel.com), Dalsa (Waterloo, ON, Canada; www.dalsa.com), and The Cooke Corporation (Romulus, MI, USA; www.cookecorp.com), offer system designers high-resolution images with both a high dynamic range and signal-to-noise ratio (S/N).

Full-frame cameras such as Atmel’s 2300 × 3500-pixel, color 12-bit Camelia C1 8M and Dalsa’s 4008 × 2672-pixel, 14-bit TF 11M4 use full-frame sensors in their designs. Consequently, a chopper/shutter can be placed in front of the camera to help obtain an image from the camera’s CCD during its integration time. “To mount these electromechanical shutters onto each manufacturer’s camera,” says Stephen Pasquarella, vice president of engineering at Vincent Associates (Rochester, NY, USA; www.uniblitz.com), “requires understanding of the thread mount of each individual camera.”

Unfortunately, each camera manufacturer uses a different camera-mount standard. Some Dalsa cameras, for example, use a M72x.75-mm thread, while many Atmel cameras feature a M51x.75-mm thread. For its part, Cooke opts for a flange-mount interface. As explained in the ISO 965-1 standard, this metric fastener size designation (M) specifies both the nominal diameter and thread pitch in millimeters separated by the symbol “x”. “Thus,” says Pasquarella, “before specifying a shutter for a frame-transfer camera, it is necessary to consider whether any adapter will be required between the camera housing and the shutter.”

To synchronize the integration time of the camera’s CCD with the electromechanical shutter, an electro-optical controller must be incorporated into the system. In most systems, this controller uses an external TTL trigger output from the camera to close the shutter after each integration period. For its range of Unibliz shutters, for example, Vincent Associates offers relatively inexpensive ($625) controllers.

“Some of Atmel’s Camelia cameras may not provide direct TTL signals to trigger the shutter controller,” says Pasquarella. “In these cases, it is necessary to use an LVDS adapter to convert the camera’s LVDS control signals to the TTL levels required to trigger the shutter driver.”

When integrating these shutters into very-high-resolution or very-high-speed imaging systems, developers must consider both the integration time of the camera and response time of the shutter. Using Dalsa’s TF 11M4 with a CS45 (or CSR45-normally open shutter) shutter from Vincent Associates, for example, will only result in the maximum frame rate of 4 frames/s from the camera, despite the much higher 15-Hz burst frequency rating of the shutter. Similarly, area-array cameras based on devices such as the CCD37 from e2v technologies (Chelmsford, UK; www.e2v.com) that feature an integration time of 1 ms provide speeds that cannot be matched by shutters that expose at 25 ms.

“Because these cameras may be used in enclosed environments, shutter replacement or upgrading also becomes an issue,” says Pasquarella. “Usually, users can expect a mean time between failure of approximately 3 to 4 million cycles when using our CS45 type mechanical shutters,” he says. “And if these are used in systems where the camera housing is difficult to reach, then removing the optical system and replacing or upgrading the shutter may prove difficult.”

Vincent Associates has a novel approach to this problem. In its QCS45 Quick Change 45-mm shutter, the company has developed a design that consists of a case, cover, and carrier (see photo). While the carrier houses the mechanical shutter and data connections, the case and cover remain attached to the existing aligned components. “By removing two screws, the carrier and shutter unit can be upgraded in the field without disassembly of the complete optical interface. This reduces system downtime-which is important in many biomedical and astronomy applications,” Pasquarella says.