X-rays find flaws in food

Robotic food processing is benefiting from the increased use of x-ray imaging to inspect products for damage caused by insects or disease and then either grade the product or direct automatic trimming robots to remove a defect. Fresh lettuces can be scanned for stones and insect damage and the image used to position and align the lettuce for automatic core removal. To take advantage of the potential of x-ray imaging, Zen Automation (Brisbane, Australia; www.zenautomation.com) teamed with Applied Sorting (Bulleen, Australia; www.appliedsorting.com.au) to incorporate x-ray sensing into robotics processing systems. Software developed by Zen Automation enables the systems to handle products presented in random orientation and position on a belt.

Applied Sorting has also released a new dual-lane version of its x-ray inspection system that enables two streams of different products to be inspected simultaneously. In addition to offering the capabilities of two machines for not much more than the price of one, the new system is expected to reduce the cost of ancillary material-handling facilities and to save floor space. The dual-lane version is targeted at inspecting frozen foods, bakery products, small goods, confectionery, dips, and powdered food products such as cake mixes and beverages.

Combined sensors provide security

Combining sensor technologies, a motion detector called Eyetec from Siemens Building Technologies (Zug, Switzerland; www.siemens.com) senses body heat with an infrared detector and captures motion patterns at up to 15 m with a CMOS sensor. Software evaluates motion patterns and uses fuzzy logic to determine object size, speed, and direction of travel. If an alarm is triggered, the detector archives the images for later use to trace the cause of an incident. Users can set the conditions for triggering an alarm-either directly at the detector or at a PC-making it possible to prevent animals from triggering the alarm because their size does not correspond to that of humans. The detector can also be set to trigger an alarm if it senses people walking in a particular direction, which means, for example, that museum staff can monitor if visitors actually leave exhibition rooms after closing. Also, by marking certain areas on a live image of a monitored room, the user can allow people to enter these zones without triggering the alarm.

null

Embedded PCs enable multiple views

Checking automotive pressure sensors in an automated production line requires viewing the sensors from different angles to check the logo, color coding, and laser printing. Multicamera machine-vision systems based on embedded PCs can be particularly effective in tasks requiring simultaneous viewing of an object from several different points of view. For this purpose, Vision & Control (Suhl, Germany; www.vision-control.com) has developed the vicosystem, which contains an embedded PC that helps connect up to eight monochrome or color cameras of differing resolutions and image-acquisition speeds. On startup of the system, all the attached cameras are automatically recognized and parameters established based on the company’s pictor machine-vision library. The PC-based vcwin user interface is used to create the inspection sequence. A dedicated image data bus is available for up to four cameras.

null

EMVA meeting draws record attendance

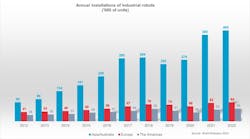

The 4th European Machine Vision Business Conference of the European Machine Vision Association (EMVA; Frankfurt am Main, Germany; www.emva.org) took place in Tampere, Finland, from June 30 to July 1. With close to 150 attendees, it attracted almost 50% more participants than the previous year. Four different conference tracks focused on machine vision in Finland, new technologies, business trends, and machine-vision markets.

The EMVA General Assembly re-elected the Executive Committee for a seond term of office. For the next three years it will continue to be composed of EMVA president Gabriele Jansen of ISRA Vision Systems (Darmstadt, Germany; www.isravision.com), vice president Mats Gokstorp of SICK IVP (Linköping, Sweden; www.sickivp.com), treasurer Toni Ventura-Traveset of Datapixel (Madrid, Spain; www.datapixel.com), Don Braggins of the UK Vision Industry Association (Royston, UK; www.ukiva.org), and Martin Wany of AWAIBA (Madeira, Portugal; www.awaiba.com). The EMVA annual conference in 2007 will be held in Lyon, France

GigE system checks cans

Agro Dutch Industries (Chandigarh, India; www.agro-dutch.com) produces 85% of the mushrooms grown and exported in the country. Argo Dutch is expanding operations to include the manufacture of its own cans to ensure high-quality products and expand export sales and because cans make up to 20% of the cost of the final product.

The company recently chose Applied Vision (Akron, OH, USA; www.appliedvision.com) to design and manufacture the inspection system for a new line. The operation will include India’s first full-aperture, easy-open end line and will be fitted with Applied Vision’s Genius inspection system based on digital Gigabit Ethernet technology. The Genius Food End Inspection System can automatically detect defects such as compound skips, foreign objects, dents, scratches, and curl defects. Integrated alarm functions also notify the operator of process trends so the cause of the defects can be identified and corrected, reducing overall spoilage.