AUTOMOTIVE INSPECTION: High-speed camera helps analyze engine fluid flow

By using high-speed imaging systems, Professor Christoph Brücker, Head of the Fluid Mechanics & Machines department at the Institute for Mechanics and Fluid Dynamics at the University of Freiberg (Freiberg, Germany) has embarked on a project to test the efficiency of internal combustion engines.

"Our goal is to create car engines that need less fuel to generate more power. To do this, the motion of the fluids in the engine must be analyzed. This analysis provides insight into how the air and fuel injected into the engine might be modified to generate power more efficiently," Brücker says.

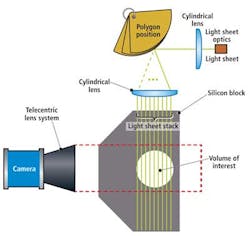

To analyze the speed and direction of the fluid, tracer particles are first injected into the engine and illuminated with a laser light sheet. By scanning a large number of image planes as the laser beam is shifted, this scanning Particle Image Velocimetry (PIV) technique and allows a single camera to be used to make 3D measurements of the fluid flow. By comparing successive images, the velocity of the fluids and which direction they are moving can be calculated.

To begin his study of fluid dynamics, Brücker and his colleagues built internal combustion engines with special viewing windows. Then, using a Phantom v1610 digital high-speed camera from Vision Research Ft. Wayne, NJ; www.visionresearch.com), images and viewed, recorded, and measured the velocity of the fluids inside the engine from that map.

"The Phantom v1610 camera can capture 16,000 fps at full resolution and 1,000,000 fps at reduced resolution. "Frame rate is important when studying the flow of fluids. The v1610 enabled us to map the 3D velocity within one complete cylinder of a car engine. With the camera, we discovered the 3D nature of the flow structures and vortices. This helped us to understand the dynamics of what's happening inside the engine," Brücker explains.

Based on Vision Research's proprietary 1280 x 800 CMOS sensor, the v1610 sensor features 28-micron pixels that increase the sensitivity of the imager. "Since a traditional lighting setup could not be used, the only lighting was the light from the diffused laser sheet. However, that proved to be sufficient." he says.

Imaging at such high-speeds also demands that a large amount of data be stored rapidly. Using the v1610's 96GByte of on-board of memory and Vision Research's CineMag interface allowed Brücker to transfer images from camera memory to non-volatile storage in a matter of seconds.

Brücker's experiment is ongoing, and one that he believes will have significant impact on the fuel emissions of today's automobiles. "With the data captured with the v1610, our research team now better understands the dynamics of internal combustion engines," he says.

Vision Systems Articles Archives