Unmanned aerial vehicle (UAV) company Aeryon Labs (Waterloo, ON, Canada; www.aeryon.com) together with Pix4D (Lausanne, Switzerland; www.pix4D.com) and PUC University of Rio de Janeiro (Rio de Janeiro, Brazil; www.puc-rio.br/english) used a UAV and image processing software to create the first 3D model of Brazil's famous Christ the Redeemer monument.

Standing nearly 125ft tall and 92ft wide, Rio de Janeiro's Christ the Redeemer statue is an imposing and impressive sight. Using a technology such as LIDAR for 3D reconstruction is not possible, since it cannot scan the entire statue, due to its size, location and accessibility. Prior to this project, all previous 3D models and replicas of the statue were designed by hand.

Looking to create the first accurate 3D model of the monument, NEXT Lab of PUC University contacted Pix4D to determine if this could be achieved by using imaging software and UAVs. Up to the task, Pix4D contacted Aeryon Labs for data acquisition hardware, while PUC's NEXT Lab tackled project logistics, including special permission to fly UAVs at the Christ the Redeemer heritage site.

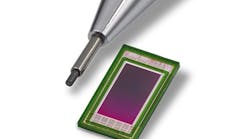

For image acquisition, Aeryon equipped its Scout UAV-a vertical takeoff and landing quadrotor-with a customized imaging payload. A WG-4 camera from Ricoh (Tokyo, Japan; www.ricoh.com) was integrated into a custom gimbal, and the camera and UAV were both controlled through a touchscreen tablet. Featuring a 1/2.3in 16 MPixel CMOS sensor, the Ricoh WG-4 camera is a waterproof, dustproof camera that is designed for outdoor applications. At full HD, the camera acquires images at 30fps.

Images were collected by the customized Scout UAV for six consecutive mornings in late October, for a total of 3,584 images that were acquired during 19 separate ten-minute flights. Of these images, 2,090 of them were loaded into Pix4Dmapper Pro desktop software to convert them into the 3D model. The 3D reconstruction process was divided into three main parts: statue, base, and surrounding area and 9 sub-projects to help manage the variations in image capture.

Signal reflectance, according to Aeryon, was one of the main challenges faced, and due to this, this affected the geotag accuracy. As a result, the sub-projects were processed without geotags. The sub-projects were merged using 82 manual tie points, while Pix4Dmapper's point editing tools and annotating feature were used to crop out background points, such as the sky. Lastly, a linear measurement, taken onsite by the project team, provided the correct scale for the final result.

The final 3D model is available as a point cloud of 134.4 million points (97.6 million for the statue, 30.7 million for the terrace and 6.1 million for the surroundings) and as a full 3D textured mesh of 2.5 million triangles with a texture of 16,384 pixels x 16,384 pixels. It will be used by PUC University for upcoming projects in the near future.