Data Matrix codes provide positional feedback in vision systems

Vision-based Data Matrix code readers have been widely used in industrial settings to verify that products have passed specific points on production lines.

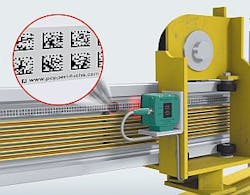

Engineers at Pepperl+Fuchs (Twinsburg, OH, USA) have expanded the scope of such systems by developing a camera-based vision system that reads Data Matrix codes to provide positional feedback along an automation system's path.

The PosiTrack PCV Data Matrix positioning system uses individual Data Matrix codes arranged beside and above one another in a unique code band that is placed along the travel path of a carrier rail. The PCV camera-based read head moves along the rail, capturing images of the codes, which are then decoded to provide an exact position of the read head in both X and Y coordinates with a +/- 0.1-mm accuracy.

The company believes that the system could be used in many factory automation applications where linear feedback is required, such as in automated storage and retrieval systems, lifts, and rotary turntables. The ability of the system to follow curved paths also makes it suitable for monitoring and controlling overhead monorails.

Unlike contact-based rotary encoder systems, the PosiTrack’s optical-based system is free from wear. The fact that the codes can be read even when large segments of the symbols have been lost or destroyed adds to the reliability of the system.

If a code strip does become damaged, however, the company offers online, web-based software tools that allow a user to generate and print replacement code sections.

-- Posted by Vision Systems Design