Short-wave infrared enhances machine vision

Light source selection: one key to a successful short-wave infrared imaging application.

Martin H. Ettenberg, James Gardiner, and Mark Kolvites

Most machine vision and image processing system developers have deployed cameras sensitive in the visible band for quality control, process control, or in applications requiring the differentiation of objects. Traditional visible-band methods include broadband white light, which allows the camera to see all the visible colors. Or to more effectively observe certain colors, developers may choose light of specific wavelength(s) such as red, blue or green.

For such visible-band applications, developers of illumination systems for use in the machine vision and image processing market have done an excellent job producing a wide variety of commercial-of-the-shelf lighting options in various form factors and colors. However, as developers turn to non-visible band imaging methods, illumination can become a more challenging proposition.

Imaging beyond the visible

One such non-visible spectral band is the short-wave infrared (SWIR) band (defined here as 750-2600nm). Many materials that appear similar in the visible spectrum, look very different in SWIR. Figure 1 shows 4 different liquids (water, acetone, TCE, and isopropyl alcohol). All appear clear in the visible, but very different when imaged with broadband light in the SWIR.

Figure 1. Four liquids (water, acetone, TCE, and isopropyl alcohol) that appear clear and transparent in the visible (top) are very different when imaged in the SWIR band (bottom).

In the visible band, today's silicon cameras enable imaging from approximately 400nm to 1050nm, just beyond the visible and into the near infrared (NIR) band with readily available light sources at wavelengths of 850 and 950nm. However, seeing beyond this range with reflected light requires another detector material such as Indium Gallium Arsenide (InGaAs), Mercury Cadmium Telluride or Indium Antimonide camera.

Since reflective properties of different atomic structures vary in the SWIR band, an uncooled InGaAs camera provides a simple way to image from 400nm to 1700nm enabling easy differentiation of many materials that often look similar in the visible band.

Figure 2 shows multiple epoxies that look either clear, dark, light or are similar in color to the substrate in the visible band. The various epoxies and caulks use different materials with fillers whose colors almost match in the visible. However, in the SWIR, they appear different from one another, especially against the background where it's commonly desirable for epoxies to match the substrate in the visible.

Figure 2. Images of various epoxies of different colors on an Aluminum background in the SWIR (left) and visible (right). The reflectivity in the SWIR is very different from epoxy to epoxy as well as against the background. The color of the epoxy even if it is clear is not relevant in the SWIR.

Wavelength is a function of temperature

Imaging is conducted by either reflectance, where the object is illuminated with an external light source, or, if it is hot enough, by measuring the objects' emission of light. When an object is illuminated the object reflects photons from an external light source to the camera. The angle of the light, wavelength of the light, and its composition will directly affect the reflective properties of the object.

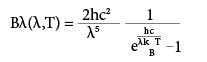

Alternatively, objects emit light at all wavelengths but the amount of light is dependent on the object's temperature. A blackbody is considered a perfect emitter of radiation. Assuming an object as a perfect blackbody, Planck's law describes the emission as:

Where l is wavelength, c is the speed of light, h is the Planck Constant, kB is the Boltzmann constant, and T is temperature in degrees Kelvin.

SWIR thermal imaging

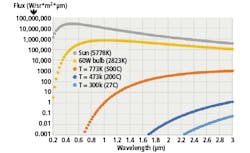

Figure 3 is a plot of emitted light by wavelength for different temperature blackbodies. Since all objects are really imperfect blackbodies, the amount of emitted light is tempered by the emissivity, which is a function of wavelength.

Figure 3. Blackbody emission by wavelength for objects at different temperatures. As the temperature goes up the emission becomes much stronger and the wavelength peak emission moves to shorter wavelengths.

Since emissivity is a function of wavelength and the physical properties of an object, when an object such as a coal glows red, it's obviously hot and should not be touched. As seen in Figure 3, a 500°C perfect blackbody emits enough energy at 700-750nm in the red to be seen by human eyes. For temperatures below 500°C, though the object may still be too hot to touch, it is not visible to human eyes because the emission at red combined with the emissivity is too low for it to appear red.

Using infrared cameras that detect light beyond 750nm, enables easy hot-object detection. Typically, this is done with long wave infrared (LWIR) or mid-wave infrared (MWIR) cameras but it can also be accomplished with SWIR cameras, depending on the object's temperature. For example, Figure 4 is a soldering iron glowing in the SWIR. At approximately 250°C, it glows enough to illuminate a person in a dark room, essentially acting as a light bulb in the SWIR.

SWIR thermal imaging is commonly conducted at temperatures above 100°C to about 2000°C depending on the application. Below 300°C or in broad daylight, MWIR or LWIR thermal imagers can detect hot objects easily. However, indoors or with very hot objects SWIR works quite well.

In the visible wavelength band, external light sources are required to illuminate objects that are not hot enough to emit the required number of photons for visible cameras to detect. During imaging, external light sources emit photons that are either reflected or absorbed by the object in question.

Different colors appear light or dark depending on how much of that wavelength of light is reflected from the object due to the illumination. In a lightbulb the filament is heated to a hot temperature (~2800K) and it emits many photons in the visible range which allows objects in a room to be seen. Figure 3 shows the sun's blackbody curve and the amount of light emitted from it versus a lightbulb.

Figure 4. Image of author in dark room with soldering iron providing light in the SWIR band from 0.9-1.7μm. Soldering iron is <300C. Hair and skin in SWIR look different than visible band.

While the lightbulb has a similar shape curve as the sun, it's lower temperature yields less overall emitted light at any given wavelength. More importantly the light bulb has more photons in the red band compared to blue and green. That's why objects appear redder indoors then when illuminated by the sun where the ratio of red photons to blue or green is very different. This is why objects appear different indoors because the combination of wavelengths emitted from the bulb are different from the sun, so the amount of light reflecting off of the object will also be different.

Incandescent bulbs such as this 60W bulb are no longer readily available, and most modern-day machine vision illumination is provided by Light Emitting Diodes (LEDs). LEDs are semiconductors that emit a specific wavelength of light or a very small range of wavelengths of light, usually + or - 50nm (with many high end LEDs , +/- 15nm) around a specific wavelength.

In the visible region we have developed many types of LEDs that provide the correct color illumination for the scene. Lights for machine vision are generally specified by color desired or color temperature desired (red, green, blue, or white at 6000K, etc.).

6000K white light

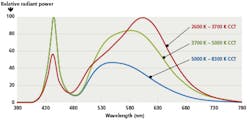

Lux or illuminance specifies light brightness, or how many photons a white light visible source emits. For single- or multi-color LED sources, light is specified in mW/cm2, and lux is a measure of white light. By combining multiple LED colors, white light or various color temperatures of light can be simulated. Figure 5 is the spectrum of a 6000K white light from Metaphase Technologies (Bristol, PA, USA; www.metaphase-tech.com). This is simulating a 6000K blackbody in the visible band, where it is very effective.

Figure 5. Wavelength output of various Metaphase LED white light sources. The LEDs attempt to simulate a blackbody at those temperatures by shifting the peak wavelength.

However, visible LED illumination is completely ineffective for the new generation of SWIR machine vision cameras. Such cameras typically range in sensitivity from 400nm to 1700nm or 1000nm to 2600nm depending on the type of image sensor used. In the past a 6000K blackbody would be a very effective broadband source for these cameras but today's white LED sources generally do not provide any light beyond 785nm.

The machine vision lighting industry has developed NIR sources that generally use LEDs of 950nm or 850nm wavelengths, enabling imaging beyond the visible. However, this is fairly limited in spectrum to one or two wavelengths. They enable visible cameras that are silicon based to image beyond visible to the near infrared. However, to image beyond the NIR range into the SWIR, newer light sources are needed that emit at longer wavelengths than today's visible LED light sources.

New, low cost SWIR linescan cameras made with InGaAs image sensors can see visible light as well as SWIR light from 400nm to 1700nm. As mentioned previously, incandescent lights can be used with these cameras because they are essentially blackbody sources that emit a broad range of wavelengths from 400nm to more than 2500nm depending on the glass used to encase the bulb.

However, since the market has moved to LEDs, most sources are very specific in wavelength with a bandwidth of +/-50nm typically. While one may consider these white light visible LED sources as broadband in the visible spectrum, because they are a combination of many LED colors, they will most likely not be broadband for the NIR and SWIR wavelengths.

Now that Vis-SWIR detector systems like the LineCam12 from Princeton Infrared Technologies Inc. (Monmouth Junction, NJ, USA; www.princetonirtech.com) are available, light source selection must consider wavelengths beyond the usual Red, Green, Blue, Ultra-Violet, and NIR sources at 850 or 950nm.

Vis-SWIR broader-band spectrum

New LED illuminators in the SWIR now make specifying these IR wavelengths less complicated. For example, Metaphase has recently developed several SWIR LED sources in this range that can be combined to form various SWIR color combinations or create the Vis-SWIR broader-band spectrum. Some imaging conditions may not necessarily need a broadband light source in the SWIR, where the goal is identifying specific reflective or absorptive properties in the objects to be inspected, rather than in the visible were a broadband source would be required to, for example, compare the green color versus the red in an image.

Figure 6. Coffee beans, rocks and sticks imaged with a visible camera and SWIR camera with 1450nm light. The objects are all shades of brown making differentiation difficult in the visible but very simple in the SWIR where the coffee beans are very reflective.

Instead, by using a specific wavelength of light, object A can be easily differentiated from object B, in the SWIR, even though they may appear the same color in the visible band. For example, moisture content in objects clearly exhibit this phenomenon. Figure 1 shows that water is very absorbing in the SWIR band specifically at ~1400nm. In Figure 6, coffee beans are easily distinguished from rock and wood material. On a black background, this would be a difficult proposition for a visible camera to sort the rocks and twigs from the coffee beans, with all of them being brown in color.

In the SWIR band at 1400nm (using a Metaphase 1450nm Peak SWIR source) it is very easy to see the coffee beans as they are very reflective yet the rocks and twigs are not very reflective and appear dark. The material of the various objects in question absorb and reflect the light uniquely, making differentiation in the SWIR much clearer than would be possible in the visible. This same, spectrally unique contrast differentiation, is important in many other applications where moisture and/or dryness matter.

Conclusion

Light source selection in the SWIR is very critical to achieve a successful imaging solution. The SWIR band can enable differentiation and detection of defects which are invisible to the naked eye. To image specific traits developers must understand how to specify the correct light source. Standard visible LED lights will be ineffective, so it is important to understand the reflective properties of the materials that are being analyzed in the image. This allows for the proper matching of the correct light source and camera to simplify the machine vision application and eliminate the need for expensive and intensive processing algorithms in the visible band.

Martin H. Ettenberg, Ph.D., from Princeton Infrared Technologies (Monmouth Junction, NJ, USA; www.princetonirtech.com); James Gardiner, Mark Kolvites from Metaphase Technologies, Inc. (Bristol, PA, USA; www.metaphase-tech.com)