Real-time signal processing SIMULATES TARGET PRACTICE

Real-time signal processing SIMULATES TARGET PRACTICE

By Marc Couture and David Brownhill

Deserted islands have long been used by the US Navy for target practice. But the damage caused by these tests has caused concern among islanders and environmentalists. In response, the Navy has created a simulated or "virtual" island--an expanse of ocean populated with hydrophones (where naval vessels can test their firing accuracy.

The Naval Undersea Warfare Center (NUWC; Newport, RI) has established a virtual island at the underwater range in Barking Sands, Kauai, Hawaii. Mapping coordinates of the ocean`s surface to an array of underwater hydrophones creates the virtual island. When surface vessels fire at the ocean`s surface, the resulting detonations or surface impacts are detected by hydrophones whose electrical signals are mapped to a simulated island. Vessels bombard this virtual island without the adverse environmental effects of shore-based bombardment.

Processing hydrophone data

To process data from numerous hydrophone sites, the warfare center chose to build a VME-based system using parallel digital signal processors (DSPs). The 21-slot system is controlled by a 2CE SPARC-based CPU from Force Computers (San Jose, CA) and contains an Inter-Range Instrumentation Group (IRIG) time stamper, a sample-clock generator, hard drive, and 16 CV4 boards from Spectrum Signal Processing (Burnaby, BC, Canada; see Fig. 1) Each of these boards contains eight TMS320C40 DSPs from Texas Instruments (Dallas, TX).

To optimize the virtual-island application, the warfare center populated each VME board with four of Spectrum`s MDC40TA modules. Each module contains a 14-bit, 250-kHz ADC, 100-kHz DAC, and two DSPs.

In operation, signals from hydrophones are fed to ADCs on each module where they are digitized. Each hydrophone in the receiver array is assigned one of the modules that, in turn, is charged with real-time detection analysis. Individual analog output signals from the hydrophones are brought to each module through the VME board. Signal routing continues through the board and onto the modules through 12 user-defined pins before reaching the ADC for digitization. This prevents cable clutter of the front panel of the VME system.

All of the ADCs on each module are synchronized using the sample-clock-generator board of the system. The host CPU processor collects recorded detection data from the module`s C40 communication port and is responsible for time-tagging the detection event using the IRIG and passing data to a tracking computer.

Detecting explosions

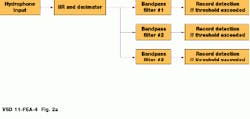

Each module`s ADC connects directly to one C40 over a 32-bit local bus, decreasing programming complexity and latencies associated with I/O transfer. ADCs on each module digitize incoming hydrophone signals. Digital data are then passed through three band-pass filters programmed to detect events in a specific portion of the frequency spectrum (see Fig. 2).

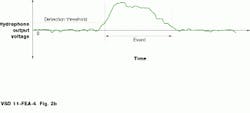

Whether a legitimate impact or explosion has occurred is determined by hydrophone amplitudes exceeding certain voltage thresholds. In this system, two possible types of threshold were incorporated--a fixed voltage level defined by a system operator and another that accounts for ocean background noises.

Average background noise is continuously updated by taking the average of most recent samples. Once a detection occurs, DSPs start to record pulsewidth, peak, risetime, and current average noise parameters and, most important, the sample number that represents where the rising edge crossed the detection threshold. Of the three band-pass filters, two or more must detect an event for it to be passed to the host CPU. If at least two of the filters indicate an event has occurred, data are placed into DSP memory, where the host CPU can retrieve the information. Because sample numbers are synchronized across all of the DSP modules and time-tagged by the IRIG, a tracking computer can localize impacts or explosions in space and time.

At present, the acoustic processing system is being used to process real-time events in the temporal domain. However, because the system is programmable, new functions such as frequency-domain analysis can be added. This would allow future DSP-based systems to be adapted for sonar analysis if required.

Processing hydrophone data in real time allows the US Navy to bomb virtual islands.

FIGURE 1. Twenty-one slots of a VME chassis make up the Naval Undersea Warfare Center`s acoustic signal-processing system. Running under control of a SPARC CPU board, the system time-correlates hydrophone signals from explosions at sea to create a simulated virtual bombing island. Signal processing is performed by16 DSP VME boards. Each DSP VME board in the system can hold up to eight DSPs, configured as two processor modules. Each module is responsible for processing one channel of hydrophone data.

FIGURE 2. Incoming hydrophone signals are continuously monitored and passed through three band-pass filters that each look for detection events in their assigned portion of the frequency spectrum (top). When a hydrophone`s output voltage reaches a detection threshold, the system`s DSPs start to record event parameters such as pulse width and the voltage at which the hydrophone`s rising edge crossed the detection threshold (bottom).

Software is key in programming DSPs

One of the problems facing developers of multiple digital-signal-processor (DSP) systems is programming. Often tools are unavailable or inadequate for the task at hand. But, by choosing VME-based CPU and DSP boards from off-the-shelf suppliers, the Naval Undersea Warfare Center (NUWC; Newport, RI) took advantage of ready-to-use operating systems, DSP development tools, and interprocessor utilities.

A Sun Microsystems (Mountain View, CA) SunOS 4.1.3 operating system running on a Force Computers (San Jose, CA) 2CE CPU board controls the 21 boards used in the system, and a Texas Instruments (Dallas, TX) optimizing C compiler was used to program the individual DSPs. Spectrum`s software utilities allowed the NUWC engineers to download and execute code on each DSP and transfer data blocks between the CPU and DSP boards. Spectrum`s interface library provides access to DSP memory on each module without the assistance of application software. This allows detection events to be transferred rapidly from each module that records an event to the host CPU.

For debugging, the warfare center used Spectrum`s DB40 C source-level debugger. To debug each DSP, a debugger window can be launched for each DSP. This allows debugging of parallel processes. Because a test bus controller was implemented on each VME DSP board, test functions can be carried out over the VMEbus from within SunOS and no emulation hardware is required.