Imaging system identifies suspects

UK National Automated Fingerprint Identification System quickly returns fingerprints based on match probability, leading to the arrest and conviction of criminals.

By R. Winn Hardin,Contributing Editor

When a Bristol University (UK) student was struck and killed by a stolen car, police quickly searched the car's interior for latent fingerprints. A partial print of good quality was lifted by officials and analyzed for identifying minutia: ridge endings, whorls, and bifurcation. Police could only hope that the fingerprint would find a match among the 5.5 million sets of fingerprints in the UK's national fingerprint archive.

Instead of waiting days or weeks for a match, however, police officials found 15 potential matches within 10 minutes in the Avon and Somerset County areas thanks to the UK National Automated Fingerprint Identification System (NAFIS), which returned the 15 prints based on match probability. This led to the arrest and conviction of the driver of the car that killed the student.

FIGURE 1. Agris-Schoen image-acquisition apparatus includes a support stand to hold the assembly over the surface being imaged. From the support arm, two brackets hold the calibration lasers, with the camera securely mounted in between. A rack gear allows the technician to raise or lower the entire optical assembly until the distance is adequate for 500 dpi resolution. The lasers can be directed independently once the proper distance between the latent fingerprint and the camera is reached. After the laser dot and laser line are aligned, the object with the fingerprint can be moved or replace, and the technician adjusts the rack gear until the laser dot and line are again aligned, meaning that the proper distance has been achieved.

That quick arrest was due in large part to the work of TRW Systems Business Segment (Fair Lakes, VA) in conjunction with Agris-Schoen Vision Systems Inc. (Alexandria, VA). They have developed a latent-fingerprint imaging system that uses lasers, a 100% fill-factor Eastman Kodak (Rochester, NY) CCD camera with fixed optics, and a variety of lighting and filters to digitally 'lift' fingerprints at a guaranteed resolution of 500 dpi (see Fig. 1).

Software developed by Agris-Schoen displays the image on a Camera Mark workstation. A technician subsequently identifies up to 126 minutiae and sends the vector-converted information to the central database. There TRW's search software compares the suspect fingerprints with the UK's national fingerprint database—turning an operation that previously took days into minutes (see Fig. 2).

Constant resolutionSimilar to IAFIS—a system developed by the US Federal Bureau of Investigation—the success of NAFIS automatic searches depends on accurate correlation of the resolution between a submitted fingerprint and those in the national database (500 ±5 dpi). The Camera Mark workstation actually gets it to ±1 dpi, according to Agris-Schoen president and head of engineering Robert Schoenberger, because the ±5 dpi is the error budget for the entire system, including processing. "If you took the image at 600 dpi, your vectors would be different and you wouldn't get a match," explains Schoenberger. "The nice thing about vectors is rotation doesn't matter. It's easy to accommodate five- or ten-degree rotations in the comparison algorithm.One key factor is that the Camera Mark workstation compensates for variations in height. Therefore, the image does not have to be resized.

Agris-Schoen was asked to develop an image-acquisition system that would accommodate the different lights and filters needed to visually isolate a chemically treated fingerprint from a surface, regardless of the size or shape of the surface. The Camera Mark imaging system includes a modified Bogen/Manfroto (Ramsey, NJ) TC-2 copy support stand, which consists of a flat platform, and a camera support post and three stand-off brackets that hold the camera directly over the fingerprints; the remaining two brackets hold the line and point lasers.

Schoenberger chose the Kodak Motion Analysis Systems Division (MASD; Rochester, NY) Mega-Plus 1.4 I-model digital video camera with mechanical shutter because of its square pixels and 100% fill factor. (Kodak MASD has since been purchased by Roper Scientific; Tucson, AZ) "We needed a 100% fill factor to meet the AFIS [and therefore NAFIS] spec. In the past, 100% fill factor and mechanical shutters were linked because of how the chip was made. Each pixel was collocated with a voltage buffer. Now there are some electronic-shutter cameras that move the voltage area beneath the light-sensitive laser, but those weren't available in 1996 when we selected the camera," he adds.

Schoenberger attached a Schneider Optics Inc. (Hauppauge, NY) Componon-S 50-mm f/2.8 fixed lens with an extension tube to the Kodak camera. The camera and lens configuration is calibrated for optimal focus at 500 dpi at the factory, which is why a fixed lens was chosen. "With a zooming lens, the odds of a technician getting it right at 500 dpi are very low," Schoenberger says. Fine adjustments can be made by TRW engineers on-site through a positioning screw during servicing, if necessary.

The Schneider lens was chosen because of the Camera Mark's need for a high-end modulation-transfer function of 60 line-pairs/mm and subsequent line-pair requirements at declining contrast levels. "Basically, [the lens] was designed for high-end copiers and photo enlargers," Schoenberger says. Agris-Schoen also commissioned Schott-Fostec (Auburn, NY) to create a special 8-in. ringlight that would fit the stand and direct the light at an angle appropriate for a standard stand-off distance to achieve the 500-dpi resolution. The 8-in. ringlight uses a fiberoptic bundle plugged into a custom extender attached to a Schott-Fostec halogen light source. Similarly, the light lines and spots receive their light via fiberoptic bundles plugged into the same custom extender. Only one set of lights is active at one time. Also, there is one set of color filters for the light source and another for the lens. The filters for the light source come from Schott-Fostec. The filters for the lens come from Tiffen (Hauppauge, NY).

The Camera Mark apparatus also uses two Lasermate (Walnut, CA) red laser-diode modules—one focused to a point, the other to a line. Positioned approximately 45° off the optical axis, the lasers allow the technician to quickly place the camera at a distance that will deliver 500 dpi. A custom-made calibration device provides white cross inside a white rectangle on a black background under the camera. The screen shows the technician a live image with an outline of approximately where the target should be placed. The image is fed through a parallel, low-voltage differential-signaling variation of a RS-422 cable to a Coreco (St. Laurent, Canada) digital Viper frame grabber. The NAFIS acquisition software finds the rectangle that has precisely known dimensions and then calculates the resolution. If the resolution of the image is greater or less than 500 dpi, the acquisition software tells the technician to either raise or lower the optical system on the Bogen support stand using the friction gear.

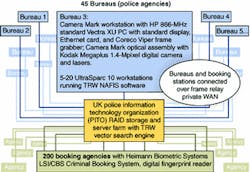

"We were familiar with the software for the frame grabber, which was why we went with the Oculus F64. It came with the ability to grab an image, look at individual pixels, write individual pixels, and do some graphics. Half-way through the life of this project, the board was phased out, so we switched to the Coreco Viper. We rewrote the ODX software in Coreco's Sapera. Edge detection and other features we did our self because we didn't want to pay third-party licenses on the 50 systems the original design requested." Today, there are 43 bureaus using 13 Camera Mark workstations (see Fig. 3).

The Camera Mark workstation includes the optical assembly connected to a Hewlett-Packard (Palo Alto, CA) Vectra XU PC. When originally designed in 1996, the system shipped with a 200-MHz Pentium Pro running Windows NT for additional password and security protection. "The original Coreco frame grabber was a two-board set that allowed many operations to be carried out on the board's hardware," explains TRW senior engineer Phil Pedersen. Even with the low clock speed, it really gave real-time or nearly real-time viewing of what was coming from the camera. And that was important because people were trying to adjust the exposure and lighting and everything else. Seeing the results in real time helped them."

During early experimentation, Pedersen said, he sat with a fingerprint technician for 10 minutes while a latent print was collected. "This particular latent print was only visible using fluorescence. A highly collimated beam of blue light was used to illuminate the latent print, which then fluoresced green. Filtering out the blue frequencies at the camera lens resulted in a real-time image of the latent print. The camera could then be adjusted for an optimum image. This typically would take a long time with the camera since the technician couldn't immediately see the result. Normally, using photography and bracketing the shots with film would have taken three to four days. That's the increase in efficiency that you see with a digital camera over a film camera," Pedersen says.

When the Camera Mark workstation shipped, the PC was upgraded to the Viper frame grabber and a 866-MHz Pentium III (also an HP Vectra XU). "Our decision to go with the HP PC was economic. We needed something that could be maintained all over the world—especially in the UK," comments Pedersen.

Fingerprint to arrestA Camera Mark PC partners with between five and 20 Unix-based Sun Microsystems (Palo Alto, CA) Ultra10 Sparc workstations at each of the 43 police bureaus connected to the UK digital fingerprint network. The Camera Mark workstation is set up as a FTP server, "because we weren't sure if the Camera Mark system would be off-site, and we did not have the option of setting it up as an ISDN line or a wide-area network."The Sun workstations pull down the digital fingerprint file in TIFF format and a second data file with identifying text information, including a 16-bit signature or key for the image. The Sparc workstation checks to make sure the image and text files from the Camera Mark workstation compare using a cyclic redundancy check and the 16-bit key. It also converts the TIFF file to a special JPEG format using a quantization table provided by the contracting agency—the UK Police Information Technology Organization (PITO), prior to sending it to the central archive.

In addition to sending the files over a private wide-area network (WAN) to the central archive, the workstations provide local access to the UK national criminal database, Phoenix. "The NAFIS system is big—terabytes of RAID and a number of big servers. That's what the workstations are ultimately connected to, but a lot of things can be done locally." Last in the fingerprint network is the 200 LS1/CBS (Criminal Booking System) from Heimann-Biometric Systems (Jena, Germany), which is connected to the PITO main archive via LAN and private WAN connections across a local frame relay network.

Fingerprint vector searches are performed by a proprietary hardware and software "black box" solution developed by TRW for NAFIS and attached to the central archive's network. Since 1998 more than 35,000 people have been identified from crime scene marks and many more than 1 million new arrestee fingerprint records have been added to the database.

Company InformationAgris-Schoen Vision Systems Inc.Alexandria VA, 22304http://www.machinevision1.com/Bogen Photo Corp.Ramsey, NJ 07446-0506E-mail: [email protected]Coreco ImagingSt. Laurent, Canada H4T 1V8http://www.coreco.comEastman Kodak, MASDRochester, NYhttp://www.kodak.com/Heimann Biometric Systems GmbHD-07743 Jena, GermanyE-mail: [email protected]Hewlett-PackardPalo Alto, CA 94304-1185http://www.hewlett-packard.comLasermate Group Inc.Walnut, CA 91789http://www.lasermate.comRoper Scientific Inc.Tucson, AZ 85706http://www.roperscientific.comSchneider Optics Inc.Hauppauge, NY 11788E-mail: [email protected].Schott-Fostec LLCAuburn, NY 13021http://www.us.schott.com/sflSun MicrosystemsPalo Alto, CA 94303http://www.sun.comThe Tiffen Company LLCHauppauge, NY 11788-3886E-mail: [email protected]TRW Inc., NAFIS ProgramFairfax, VA 22033http://www.trw.com