Users exploit low-end machine-vision-system benefits and versatility

Low-end machine-vision systems are gaining favor because of their low cost, ease of use, and application adaptability.

By Andrew Wilson, EditorAlthough low-end machine-vision systems were built mainly for inspection tasks, the benefits and reliability of these systems has led many companies to use the technology for process control. Major reasons for the adoption of low-end machine vision to perform parts-control tasks include decreasing costs, little or no programming, and user-friendly setup, control, and operation.

"The lowering costs of vision systems has opened up the market for basic inspection applications in many types of manufacturing lines," says Marc Landman, president of Vision Machines (North Reading, MA). "Such systems are being deployed for part and defect detection, size and shape inspection, and even color discrimination. One of the major trends in the machine-vision industry is host-based processing on PCs running Windows," says Landman. "The increasing power of PCs, combined with open architectures based on the PCI bus and standard development environments such as Visual C++, are sufficient for a large number of applications," he says.

"In terms of providing greater functionality, the PC has enabled simple connection of vision systems to standard network communications such as Ethernet," says Mark Sippel, vision-product-marketing specialist with Omron Electronics (Schaumburg, IL). Dedicated statistical process control (SPC) programs can communicate with vision software programs using Windows Active X controls to provide enhanced processing capabilities. Accordingly, many vision manufacturers have incorporated SPC and trends-analysis functions in their software to complement image-analysis and processing functions.

"While many customer requirements are being satisfied by manufacturers who offer high-end vision systems, low-end PC-based machine-vision systems provide a variety of solutions from simple to complex and from general to application-specific. Typical prices for these types of systems range from $6000 to $50,000," says Sippel.

No programming needed

Despite this PC-based trend, several vendors are meeting user demands from developers, manufacturing engineers, and process-control engineers for systems that require little or no programming. Although developers realize that machine vision is a key technology for both industrial inspection and process-control applications, they would rather avoid understanding the software intricacies of pattern matching, morphology, and ActiveX controls.

"Some machine-vision solutions do not require an elaborate interface, advanced communications, and high flexibility," says Sippel. "Many vision applications are basic; for example, Is the label facing the correct way on the carton? Are the instructions included on the bottle of medicine? Are all of the lead frames on the chip? Is the part oriented properly?" he adds.

Traditionally, photoelectric sensors have been the solution of choice for these straightforward applications. Because of their low cost, many systems integrators configure multiple sensors for applications requiring two-dimensional (2-D) inspection. "However," says Sippel, "setting up banks of photoelectric sensors can become nearly as costly as setting up a machine-vision system." What developers really need is a "low-end" vision system to solve basic presence/absence applications," he adds.

Plug and play

To meet these demands, several vendors have introduced enclosed, proprietary systems to perform targeted image-processing tasks such as pattern-matching, object location, gauging, and verification tasks. Although such tasks may seem limited in scope, they have been chosen by systems vendors to meet a majority of their customers' applications. Coupled with easy-to-use interfaces, such systems often allow developers to begin testing automated vision-based automated inspection tasks within days after installation as opposed to weeks for high-end systems.

Omron was first to introduce this concept more than two years ago. The company's latest system, the F150-2 machine-vision sensor, fills the niche between high-end photoelectric sensors and full machine-vision systems (see Fig. 1). Because no programming is required and all sensor setups and uses are controlled via a keypad, users can set up and implement applications quickly and easily. Either gray-scale or binary image processing can be selected, depending on which best suits the application. Providing 11 dc inputs and 21 NPN or PNP transistor outputs, or with DeviceNet communications, the F150-2 machine-vision sensor can be integrated with other plant-automation devices, including Omron programmable logic controllers or PCs over an RS-232C interface.

In addition to identifying pass or fail parts, the F150-2 sensor can store up to 23 images in memory. This enables users to pinpoint and adjust failure points. Because it allows up to 16 setup scenes and up to 16 inspection windows in each scene, the F150-2 can inspect assembled parts and identify missing or improperly placed parts, align fiducial and registration marks for robotic guidance, and detect the presence, absence, or direction of components on a printed-circuit board.

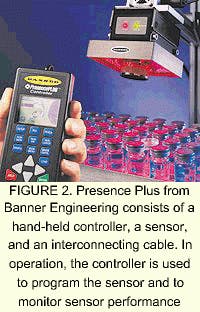

With the increasing demand for low-cost machine-vision systems, other companies have entered the low-cost imaging solutions arena. Similar to the Omron F150-2, the Presence Plus from Banner Engineering (Minneapolis, MN) consists of a hand-held controller, a sensor, and an interconnecting cable (see Fig. 2). The controller programs the sensor and monitors sensor performance.

Depending on the application, a setup mode first adjusts the target object within the sensor's pixel array, runs an autoexposure routine, focuses the sensor's lens, and lightens or darkens the image. Then, a region of interest is chosen to define a particular area within the array or to mask the area for exclusion from judgment. Last, a teach mode allows the sensor to recognize acceptable and unacceptable images by presenting a number of product examples. The controller uses the pixel counts from these examples to determine judgment criteria for subsequent sensor operation.

Before deployment, the user can enable appropriate autoexposure settings and set lighting, trigger, and output settings. Up to four different sets of parameters can be uploaded from the sensor to the controller and saved as files. These features allow parameters to be downloaded to the sensor when setting up different product runs or programming more than one sensor. After the sensor has been programmed and configured, the sensor is set in run mode to monitor pass/fail decisions, monitor pixel statistics, and view captured images.

Search and find

Accuracy, repeatability, and speed are among the most important system-processing parameters for locating objects within images. To develop imaging systems that optimize these parameters, machine-vision-systems vendors are complementing long-established techniques such as normalized gray-scale correlation with geometric-based approaches.

Cognex (Natick, MA) was first to offer such software; its PatMax package interprets the geometric shapes within objects by reading squares as line segments and patterns, such as blobs, as a combination of two arcs. Because these descriptions remain constant no matter what angle the object is at or how much its size has changed, the software can locate and measure objects with a 1/40-pixel accuracy (see Vision Systems Design, May 1999, p. 50).

Now, Cognex has combined both PatMax and the company's normalized gray-scale correlation-based search tool into a new tool called PatFind, which is embedded in the company's InSight vision sensor. This sensor consists of a DSP-based processing unit, a 640 x 480 x 8-bit progressive-scan CCD camera, and a Nintendo-like programmable controller (see Fig. 3).

"A number of nonprogrammable vision systems feature point-and-click interfaces," says Bill Silver, chief technical officer of Cognex. "But while these systems help to shorten the application-development cycle, they typically sacrifice flexibility to make development easier. What has been lacking is a configurable vision interface that combines the flexibility of a programmable system with the ease of use provided by a point-and-click interface," he says.

With InSight, applications can be created, tested, and deployed using the InSight vision spreadsheet interface. To do so, applications are configured by selecting tools and parameters from menus using the sensor's controller. InSight then automatically enters tool results into worksheet cells that can be linked together to perform functions such as locating or measuring parts.

Using the control pad, cells can be selected, cut, and pasted during configuration. Alternatively, changes to applications can be made on-the-fly during runtime. Because the InSight spreadsheet is transparent, vision tool graphics can be seen over the image as they are applied, negating the need for two separate screens.

PC-based programming

Rather than use hand-held programmable controllers to develop software, many smart-sensor vendors are using the PC as the host for systems development. In such systems, the PC is used as an application-development platform, allowing users to develop a machine-vision application. After development, the code is used to control the embedded machine-vision system.

DVT (Norcross, GA) has used this approach in the development of its Series 600 SmartImage sensors and FrameWork-based software. For example, FrameWork 2.0 software contains tools such as blob analysis, measurement, and template matching. During operation, the FrameWork software resides in two places: as a user interface under Windows on a PC and as embedded firmware in the SmartImage sensor (see Fig. 4).

To develop applications, a setup procedure is first performed using the PC-based user interface, with image processing and result determinations being performed by the embedded system. However, developers cannot create applications without purchasing the system hardware—the Series 600 SmartImage sensor.

With the trend toward producing plug-and-play vision systems, vendors are also embedding CPUs and DSPs in both smart sensors and larger embedded systems. While such designs reduce costs, developers must pay greater attention when evaluating the application software that is supplied with these systems. In some applications, system functionality may be limited by the speed of the embedded processor, memory size, and input/output capability. Indeed, because of the embedded nature of the hardware, system developers should first evaluate the software capability of such systems before purchasing the hardware.

Company Information

For information on additional suppliers of machine-vision systems, see the 2000 Vision Systems Design Buyers Guide (Vision Systems Design, Feb. 2000, p. 78).

Banner Engineering

Minneapolis, MN 55441

Web: www.baneng.com

Cognex

Natick, MA 01760

Web: www.cognex.com

DVT

Norcross, GA 30093

Web: www.dvtsensors.com

Omron Electronics

Schaumburg, IL 60173

Web: www.omron.com/oei

Vision Machines

North Reading, MA 01864

Web: www.vision-machines.com