Snapshots

Terahertz imaging aids forestry

Researchers at the University of Northern British Columbia (UNBC; Prince George, BC, Canada; www.unbc.ca) are using terahertz technology to create imaging devices that provide forest operations with the ability to see inside wood and determine the fiber quality of logs and processed wood products. The goal is to maximize the value of each tree.

Physics professor Matt Reid and his fellow researchers, working at the Advanced Laser Light Source facility (Montreal, QC, Canada; www.nrc-cnrc.gc.ca), have used ultrafast lasers to generate bursts of terahertz waves with the largest energies ever produced, which means they can see through objects in real time. “We’re now at the cusp of translating our knowledge into industrial application,” says Reid. “Where we are right now with our development of terahertz technology is where other researchers were when lasers were first invented.”

Reid is focusing his attention on the backbone of the BC economy, the forest industry, and working closely with the UNBC forestry department and Bruce Sutherland of Wolftek Industries (Prince George, BC, Canada). Forestry companies need a technology to see the insides of trees so that logs can be properly positioned in the mill for maximum efficiency. Imaging the outside of a tree is no longer sufficient since trees infested with the pine mountain beetle often have cracks inside that can greatly affect the wood quality and potential products. Terahertz technology would essentially give mill opportunities to see through objects and also see features inside these objects.

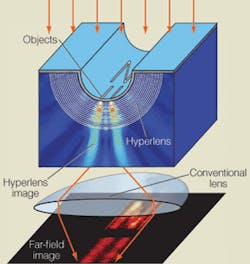

Hyperlens may enable nanoscale optical imaging

Scientists at the University of California, Berkeley (Berkeley, CA, USA; www.berkeley.edu) have developed a “hyperlens” that brings them closer to the goal of nanoscale optical imaging. The new hyperlens can project a magnified image of a pair of nanowires spaced 150 nm apart onto a plane up to a meter away.

Xiang Zhang, UC Berkeley professor of mechanical engineering and principal investigator of the study, says, “The hyperlens shows a new way to beat the diffraction limit, which would allow biologists to not only see a cell’s nucleus and other smaller components, but to study the movement and behavior of individual molecules in living cells in real time.”

The hyperlens consists of multiple layers of silver and aluminum oxide placed along the cavity of half a cylinder carved out of quartz. When an object is illuminated, its evanescent waves travel through the lens. As the wave vectors move outward, they are progressively compressed, which allows the image of the objects to be magnified by the time it reaches the outer layers of the hyperlens. At this point, it can be captured by a conventional optical lens and projected outward onto a far-field plane a meter away.

The researchers used nanowires that were 35 nm wide and inscribed onto an inner layer of chrome that sits atop the hyperlens. In the first experiment, two nanowires were placed parallel to each other 150 nm apart. The researchers also shaped nanowires into the letters O and N for another demonstration.

Wavelets compress images at high resolution

Compressed files in formats such as JPEG and GIF tend to be too large to preserve the readability of the text. Researchers at the Centre for Wavelets, Approximation and Information Processing at the Department of Mathematics, National University of Singapore (www.cwaip.nus.edu.sg) have developed an approach for compressing document images that makes it possible to transfer a high-quality page at a very high compression ratio.

The wavelet-based document image-compression (WDIC) technique partitions and encodes separately four parts from which the original image can be reconstructed: character, picture, line, and background images. The character image can be encoded with a novel extent-based morphological matching and clustering and wavelet compression algorithm. A picture image can be encoded with a wavelet-based compression algorithm, suitable for gray-scale images. A line can be encoded with a on-dimensional wavelet-based compression algorithm. The background image also can be encoded with a wavelet-based compression algorithm.

With WDIC, a typical A4 page in 8-bit gray scale at 100 dpi can be compressed to 5k-30k. Compared with the original 100-dpi raw image, WDIC achieves a compression ratio ranging from 40 to 200 times. For a typical page at 300 dpi, WDIC achieves a compression ratio ranging from 100 to 400 times. You can download the software at www.cwaip.nus.edu.sg/demo/wdicdemo.htm.

Vision system checks bowl feeding

To determine whether a bowl feeder is delivering the right types and sizes of screws to a production line, TI Automotive (Oxford, UK; www.tiauto.com) has installed four machine-vision systems on a transfer line for automotive brake and fuel-pipe assemblies. The systems use Compact Vision Systems SBOC-Q/SBOI-Q from Festo (Esslingen, Germany; www.festo.com) to check size, orientation, and quality. The systems are used in conjunction with Festo Checkbox software to ensure that the right type of screw is fed to the assembly station. While Checkbox eliminates wrong or incorrectly oriented hollow screws on the basis of their profiles, one system also checks their internal diameter. Another system provides a high-precision final inspection. If it identifies a defective workpiece, it is electronically tagged and separated from the correct finished products. Festo CheckOpti software was used to “teach in” the components to be checked. Data for up to 256 workpieces can be stored.