Vision applications need new interoperable platforms

VSD:What applications or industries does Mnemonics serve and with what technologies?

Negin:Today we primarily serve pharmaceutical, defense, government, and electronics manufacturing. The applications generally require tools to perform automated alignment, measurement, and flaw detection, and they vary widely and wildly from customer to customer. Typically, the requirements include correction for translation, rotation, warp, and illumination nonlinearities. Frequently the applications we deal with require processing images from 40 kbytes [200 × 200 pixels] to 300 Mbytes [15,000 × 20,000 pixels]. The challenges with processing individual images of larger size are the local and global variations that are not compatible with linear machine-vision algorithms.

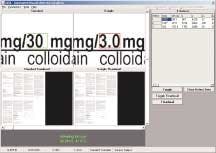

One of our newest applications is a battery-operated hand-held vision system for consumer use that will integrate a 300-kbyte color sensor with integrated pattern-recognition technology. This system has a target retail price of $35. Another of our applications requires much larger images for an “automated proofreader” that replaces a four-hour human inspection with a two- to three-minute analysis, with improved accuracy and performance. This application requires a 300-Mbyte image-capture system. These two applications have a 1000X image size range, or three orders of magnitude, but the basic software is essentially the same, with a few wrinkles.

VSD:What market changes are driving the implementation of new technologies that you choose for these applications?

Negin: Customer expectations and knowledge. It used to be that customers were very knowledgeable about technology and didn’t really have very high expectations from it. Now, with the technology becoming very advanced and with many customers not being able to keep up with it, their expectations are increasing exponentially while their knowledge is not. Basically, they want the vendor to solve the problem inexpensively, and they expect the solutions that are provided to actually work.

In addition, there are new classes of problems developing that need more and more sophistication to solve them, such as inspecting a 300-Mbyte image and finding a defect that has an area of 12 pixels-1 part in 25,000,000-with virtually no false alarms. Problems like these need new types of self-learning techniques because humans should not and can no longer be in the teaching loop.

VSD:In which areas do you see the most growth? What are users demanding from you in the design of new systems?

Negin:From our perspective for the past 10 years, we have seen that the migration of applications to new platforms is a critical need. This occurs because of antiquated hardware and software such as defunct operating systems. The demand for SID [software-independent devices] and HIS [hardware-independent software] is going to dramatically increase. This will become true within vendor companies and across supplier companies. Interconnectivity and interchangeability among components with few changes must become the norm for the machine-vision industry to grow significantly.

In a sense it’s like music CDs-the content is equivalent to software-and CD players-the hardware. Anybody can mix and match CDs and players. This implies that standard hardware and software interfaces must become pervasive so that systems can be easily configured or be self-configurable with a variety of software and hardware from different vendors. Systems must be able to recognize what they are connected to and what they have to do to interoperate. This means that universal interfaces similar to TWAIN drivers for scanners must be developed for machine-vision imagers, and that software must be able to use these interfaces to capture images and process them.

Once this is accomplished, efficient upward migration paths for machine- vision systems can be developed so that the baby-the application-doesn’t have to be thrown out with the bath water-the obsolete hardware.

VSD:What technologies and components does Mnemonics use in your applications?

Negin:Mnemonics’ approach is to develop application-specific software packages that are based on internally developed libraries. These packages interact with the imaging and capturing hardware through a BSP [board-specific protocol] layer that conditions information from the hardware into the form that the application-specific software accepts. All the software works through the concept of an FGI [frame-grabber independent] image and control buffer that is memory resident and is accessible through memory pointers by the BSP and the application.

The result of this design is that Mnemonics uses array and linescan cameras, flatbed and large-format scanners, and image streams across a network or from disk. Using this methodology, test and integration issues become quite manageable, and regression testing from image databases allows tracking of the effects of software changes and permits process validation to be systematized. This also permits us to build and reuse software tools for a wide range of applications.

VSD:How do you approach a new application?

Negin:New application developments are always approached with the following question: Does it really have to be done with machine vision? If it doesn’t really, really need to be done with machine vision, then we generally don’t want to get involved unless there are some very important economic or societal benefits.

If it passes the machine-vision question test, then we have the customer fill out a questionnaire, which is on our Web site. If that goes OK, then we determine if a specification exists and go from there. We determine budget, time to delivery, quantities, the technical problem, individual and joint responsibilities, and integration, and then get samples to quickly review. Usually we request video or a series of captured images to review.

Once we determine if we want to bid on the job, we then lay out a proposal depending on the customer’s needs, answering questions such as: Fixed price? Time and materials? Phased project with milestone and progress payments? Acceptance criteria? Scope? What to do about engineering change requests? Accelerated time frame? Intellectual property? Prototype, preproduction, or production systems?

VSD:Does Mnemonics perform its own systems integration or look to outside integrators for support or OEM suppliers for help?

Negin:We do our own systems integration generally, with the customer providing some of the work that union or trades people would normally do. We do acceptance tests at our facility or with customer material and send a report to the customer. We do on-site training and burn in test, integration, and trials. We also work as a subcontractor to other vision companies or other integrators.

VSD:What kinds of new applications do you expect to emerge?

Negin:Beyond industrial applications, I foresee vision working its way to government-security and consumer applications. Fundamentally, I see shifts from what I call “engineered environments” such as factory floors and manufacturing environments to “nonengineered” environments, such as transportation systems, roads, automotive guidance, and collision avoidance. Vision will also shift to grocery and point-of-sale stores, including automated vision-enabled checkout and people movement for market studies of product placement. And it will shift to security, surveillance, and battlefield-scene analysis.

This shift will follow the paradigm of the “cameras everywhere” society, such as ATM security, biometric ID, and very smart surveillance. This trend gets back to the idea of increased expectations of the customer-whether consumers, governments, or industry. We will see machine vision become a commodity, with prices driven down and expectations driven up.

VSD:How will OEM components have to change to successfully meet those emerging applications?

Negin:Software will become the key to most of the applications. Common interface standards, both hardware and software, will establish the trajectory for success for common vision-system platform designs and implementations. The keys to success will be how much better the components price/perform compared to their competitors, and how easily all the components can be interconnected. This improvement will build sales and markets for new products that meet common interface standards, because these products will be able to easily replace older products with a minimum of customer pain.MICHAEL NEGINis president and CTO of Mnemonics Inc. (Mt. Laurel, NJ, USA; www.mnemonicsinc. com), which he founded in 1979. He has an M.S. in pharmacology from Temple University and a Ph.D. in electrical engineering from the University of Florida. Previously, he served as vice president and CTO of Sensar (now Iridian) in developing the company’s first iris-recognition product. He has also been a professor at Temple and Drexel universities. Editor in Chief Conard Holton talked to him about trends in machine vision and image processing.