Modular architectures add flexibility to board-level designs

In 1997, Matrox Imaging (Dorval, Quebec, Canada; www.matrox.com/imaging) introduced the Genesis modular image-capture, processing, and display board for the PCI bus. This board contains a Texas Instruments (TI; Dallas, TX; www.ti.com) C80 DSP with an on-board PCI interface, custom neighborhood operation accelerator (NOA), and custom video-interface ASICs (VIAs).

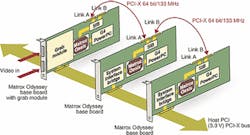

Based on a proprietary interface using VIAs, the company offers a number of optional input modules that can be attached to the board. In its next-generation of software-compatible machine-vision boards—Odyssey—the company has taken a similar design approach. But rather than using proprietary interfaces, the company has opted for a modular interface based on the PCI-X standard (see figure).

Like the Genesis board, the Odyssey board consists of a baseboard and a several plug-in modules. Containing a G4 Power PC, up to 1 Gbyte of DRAM, and a custom ASIC called Oasis, the Odyssey board provides a full 64-bit PCI-X architecture that runs at speeds to 133 MHz and delivers burst transfer rates of approximately 1 Gbyte/s to the host PC.

The Oasis ASIC, one of the first implementations of the PCI-X interface on an imaging board, incorporates the 64-bit, 133-MHz CPU bus interface to the PowerPC and a 128-bit-wide, 166-MHz double-data-rate DRAM interface capable of transferring image data at rates to 5.3 Gbytes/s. Using 22.4 million transistors, the ASIC also incorporates the next generation of the company's pixel accelerator that, together with the on-board PowerPC, acts as an imaging coprocessor.

With an array of 64 processing elements running at 167 MHz, the pixel accelerator is designed to accelerate neighborhood, point-to-point, vector-product, and adaptive-filtering algorithms. To interface to optional data-acquisition modules, Matrox has developed a system-interface ASIC that forms a bridge between the modules and the Oasis ASIC. This bridge allows PMC-like modules to be added to the board using the PCI-X interface.

Camera Link ModulesInitially, the Odyssey baseboard will be offered with three image-capture modules: two Camera Link modules and one analog interface. While both Camera Link modules will use two MDR26 connectors, the first will support a single Base, Medium, or Full configuration. The second Camera Link implementation will enable systems integrators to interface two independent Base configuration cameras to the Odyssey board.For designers using high-speed multitap analog cameras or users of scanning electron microscopes and medical-imaging equipment, the company's analog interface provides four independent 100-MHz channels that can be used independently or synchronized together. Software support for the Odyssey board will be provided by a native image-processing library and the company's Matrox Imaging Library package.

Like the Genesis family, the Odyssey supports mechanisms for display or additional processing boards. To accomplish this, the board's system-interface bridge supports two 64-bit, 133-MHz point-to-point interfaces that will allow the board to interface to future Matrox products. According to the company, these will include PCI-X-based display boards and optional boards for specific types of image-processing functions. At present, the company is currently sampling the Oasis ASIC used on the board after simulating the part both in software and using FPGA-based Xilinx prototypes.