Smart cameras aid sewing

Linking is used in the garment industry to describe the sewing together of two fabrics such as a collar onto a sweater body or the edging onto curtains. Depending on the garment to be produced, a number of linking sizes are used. Existing linking machines are very basic, and the linking step size, defined by the needle interval, cannot be modified.

Because of this, manufacturers of finished textile goods must purchase several different linking machines to accommodate different linking step sizes. Multiple linking sizes are used in the knitting industry, and different machines accommodate the production of various types of products. Skilled, highly trained operators must operate several different machines. Because the production of such fabrics demands high-precision stitching, finding qualified employees can be very difficult, a fact that prompted sewing-machine manufacturer E.R.B.E (Roanne, France; www.erbe.fr) to develop an automated linking machine that encompasses machine vision.

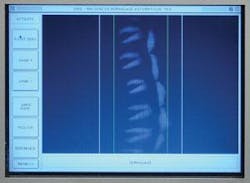

In cooperation with system-integrator Acyrus (Mours, France; www.acyrus.fr), the machine is based on a traditional sewing machine and promises to make linking easier, faster, and more reliable. Since the machine can be programmed for many different linking step sizes, a single machine can replace multiple linking machines. Furthermore, since the machine can recalculate each linking step position as the linking process occurs, the sewing needle is guaranteed to punch each link precisely (see photos).

Based on a traditional sewing machine, the E.R.B.E intelligent linking machine uses an mvBlueLYNX intelligent camera from Matrix Vision (Oppenweiler, Germany; www.matrix-vision.com) to control the needle, ensure that the correct mesh is placed along the garment’s existing edge, and ensure that the needle enters the middle of this seam. Image-processing software embedded in the camera ensures the fabric is placed correctly and controls several motors to align the needle precisely.

Because of the embedded processor within the camera and its embedded Linux operating system, all the image-processing and control tasks can be performed within the camera. In operation, the mvBlueLYNX controls three different motors of the sewing machine and the system’s ultraviolet LED ring illumination and handles the input signals from the operator’s pedals. Additionally the machine can be controlled using a touch screen, whose display and control is also interfaced to the camera.

With E.R.B.E.’s machine, the operator does not require linking skills to perform the task, merely the skills to use a sewing machine, initiate the linking process, and roughly guide the fabrics under the needle. The vision system guides the needle to the correct location.

Using the new linking machine, linking is 50% faster than manual-only methods and more reliable. Furthermore, one machine can be used for multiple mesh sizes.

Although an operator is still required, the machine accomplishes much of the important linking task. Furthermore, since only one machine is needed to accommodate many different mesh sizes, manufacturers can save money, and the quality of finished products is less dependent on operator error.