Metrology system from Boulder Imaging offers real-time part measurement

The Benchmark metrology system provides micron-level in-line (or off-line), real-time part measurement and conformance to specification for any part or material. The system’s accuracy exceeds 5 µm. Using a Centralized Inspection Point Technology (CIPT) approach, the system allows rapid parts changeover with an automated setup and self-calibration capability. It can be used for first article inspection, reverse engineering, measurement of 100% of parts, or spot inspection.

Boulder Imaging

Boulder, CO

-- Posted by Vision Systems Design

---

NEW PRODUCT PRESS RELEASE

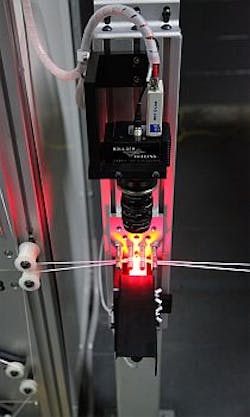

Boulder Imaging, Inc. announces in-line metrology inspection system: Vision Inspector Benchmark

Boulder, Colorado – Boulder Imaging, Inc., a leading imaging solutions company for machine vision applications, is releasing the in-line version of its Benchmark metrology inspection system.

The Benchmark system provides micron-level in-line (or off-line) part measurement and conformance to specification for virtually any part or material in real-time. The system provides accuracy exceeding 5 microns and inspection speed far beyond current CMM and laser-based measurement systems, allowing the system to be placed in-line for typical inspection applications. It can be used for first article inspection, reverse engineering, measurement of 100% of parts, or spot inspection. Benchmark also provides detailed reports for customers and ISO compliance.

“The Benchmark system is a quantum leap ahead of current laser or probe-based CMM technologies not only in terms of speed, but also inspection capability and flexibility” says Carlos Jorquera, Founder and CEO of Boulder Imaging. “Our advanced solution provides manufacturers from virtually any industry the ability to perform 100% parts inspection for measurement and conformance to spec in-line at line speeds for highly engineered and precision parts. For example, one of our customers replaced 5 CMM machines with a single Benchmark system, reducing inspection on a single part from 40 minutes to 5 seconds. Needless to say, their management team and investors are delighted with the massive cost and time savings,” add Jorquera.

Employing Boulder Imaging’s CIPT (Centralized Inspection Point Technology) approach, the Benchmark system is capable of rapid parts change-over with automated set-up and self-calibration capability that allows customers to change parts and/or inspection criteria in seconds. CIPT also allows the inspection cell to be placed on the production line quickly and easily, or moved to another position with the same ease of set-up.

About Boulder Imaging

Boulder Imaging, Inc. is the leading U.S. computer vision, machine vision and imaging specialist providing real-time image acquisition, analysis, and processing solutions for high speed, high performance, and high precision manufacturing (machine vision, quality control, and intelligent vision inspection), engineering, and scientific applications. Over the last 16 years our vision systems have successfully enabled companies and government organizations to optimize product quality, drive down manufacturing costs, and measurably improve efficiency.

SOURCE: Boulder Imaging