LIGHTING & ILLUMINATION: LED illuminators find microscopy applications

For years, tungsten halogen light sources have been the de facto choice for optical microscope illumination. With their broad spectral characteristics and low cost, these light sources can be used with a number of different fiber light guides to provide spot, backlight, or ringlight illumination.

Despite the success of these products, many lighting manufacturers are now looking to offer LED-based alternatives that will provide lower maintenance costs and power consumption. To date, CCS America (Burlington, MA, USA; www.ccsamerica.com), Schott North America (Southbridge, MA, USA; www.us.schott.com), and Nathaniel Group Inc. (NGI; Vergennes, VT, USA; www.ledfiberdriver.com) all offer light sources that they claim can be used to replace traditional tungsten halogen-based designs.

“Despite these claims,” says Mark LaPlante, a senior mechanical engineer with NGI, “system designers must have a full understanding of their application before committing to purchasing these products.” For example, in many fluorescence microscopy applications, the amount of illumination required may be the most important criterion.

In these applications, an arc lamp, such as a mercury-halide lamp, is often used in conjunction with optical filters to excite a particular narrow frequency of light. When applied to the sample under test, this light then excites the fluorescent molecules or fluorophores, causing them to emit longer wavelengths of light that are again filtered and captured by a camera system.

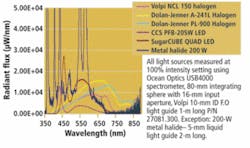

Although these mercury halide-based systems are often ten times more expensive than their tungsten halogen counterparts, they produce the highest luminance and radiance levels of any light source used for microscopy (see figure). “Tungsten halogen lamps with their wide spectral distribution are often used to illuminate specimens in optical microscopy,” says LaPlante. Here again, optical bandpass filters can be used to illuminate living cells using different wavelengths of transmitted light.

For LED illumination systems to challenge the role of tungsten halogen lamps in these applications, the system integrator must choose carefully the type of LED used and understand its spectral luminance characteristics. For example, NGI offers five types of LED-based illuminators in its SugarCube series of illumination systems—the white unit emits a broad spectrum while the colored units produce a relatively narrow spectral bandwidth. The spectral bandwidth of the red, green, and blue LED illuminators peak at 630, 521, and 458 nm, respectively, and it is at these frequencies where the maximum light intensity is obtained.

“Since the luminous intensity at this peak is equivalent to the same amount of light produced by a tungsten halogen bulb at the same frequency,” says LaPlante, “LED light sources can in many cases be used to replace these incandescent lamps.” Although there is a need to customize LED illumination systems for specific wavelengths, LEDs may not be readily available that produce the correct wavelength at the required power. However, NGI has patented a method to chemically shift the wavelength of available LEDs to any specific wavelength.

“In the same manner that phosphor materials are used to convert monochromatic light from a blue or UV LED to broad-spectrum white light, an LED of a known frequency can be shifted to produce a higher wavelength of light,” says LaPlante. Using this technique, NGI hopes to offer a range of future products that will target specific wavelengths and products that use multiple LEDs to produce broad-spectrum illumination systems.

However, determining which LED light source to choose is more than a matter of understanding spectral characteristics. One of the most confusing aspects in determining the brightness of illumination sources is how each individual manufacturer specifies the luminance of the devices. Schott, for example, specifies that its LLS white light source produces 275 lumens when the light output is measured with a 1-m-long, 13-mm bundle. Meanwhile, NGI’s SugarCube Quad White illumination source is specified at 4300 lumens.

Because of the lack of a standard way to specify these products, manufacturers offer these measurements in either units of radiant flux (in watts), lumens, or lux; each of which can be measured both at the LED source or after light has been attenuated through numerous types of optical coupling at the light source.

Because of the lack of standards, the only way to determine how the light source can perform is by conducting measurements on an evaluation unit. In a recent demonstration, NGI’s product line was indeed impressive, producing from a single LED die some of the brightest light currently achievable using LEDs.

Like Schott and CCS, NGI has also incorporated an RS-232 computer interface into its line of illuminators. In the NGI design, however, the intensity control potentiometer does not exist. Instead, one will find software-controlled, soft-key buttons that control the unit. A remote keypad lock-out feature eliminates the chance of any operator interference or error.