Camera-based gauge can replace PSDs

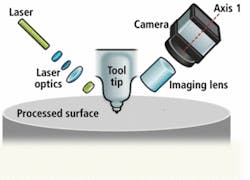

Researchers have developed a vision solution with embedded computing for distance measurement that eliminates errors associated with surface tilt and surface shape in manufacturing process-control applications. The standoff camera system determines the distance between the processing tip and the surface at the point of process.

Gil Abramovich and Kevin Harding at GE Global Research (Niskayuna, NY, USA;www.ge.com/research) developed the high-speed, camera-based distance gauge that eliminates some of the challenges associated with position-sensitive detectors (PSDs). These include performance degradation in the presence of multiple reflections, stray light, variations in the beam shape and intensity distribution, and surface tilt.

Analysis of geometrical and illumination-efficiency constraints suggested that imaging the reflection of a laser spot is the best method, so their system includes a linescan camera with resolution of 20 μm or better. A significant part of the prototype is an embedded image-acquisition and -processing unit that uses an FPGA.