Enhancing Image Quality with Melt-Fit Technology: Customizing Optics to Material Variations

What You Will Learn

- Melt-fit design adapts optical systems to the precise properties of glass batches, enhancing imaging accuracy in high-demand applications.

- It involves close collaboration between glass manufacturers and optical designers to measure and incorporate real-world glass properties into the system design.

- This technique is especially valuable when conventional symmetric designs cannot compensate for material and mechanical variations.

- The process pushes the boundaries of optical precision, enabling imaging systems to operate at the physical limits of focus, resolution, and color fidelity.

Designing optics for industrial and scientific applications demands cutting-edge technology and deep expertise to get as close to physical limits as possible. One advanced technique is the so-called melt-fit design, a process that adapts an optical system to the precise properties of the glass used in its construction. This approach enables precision in focus, resolution, and color fidelity, especially for the most demanding imaging applications.

Across consumer, industrial, and scientific imaging markets, optics are fundamental to image quality. While software-based image correction can mitigate certain defects, it often introduces trade-offs such as increased noise, higher power consumption, longer processing times, and reduced frame rates. As the engineering adage goes, “garbage in, garbage out”.

For designers of advanced vision systems, optimizing the image captured by the sensor with high-quality optics is the most effective strategy.

Mechanical and Material Variations in Lens Design

Optical design and manufacturing have gone through decades of innovation and continuous improvement to achieve a high level of accuracy. Yet as any man-made device, they are subject to variations within certain tolerances. These tolerances apply to the geometry of each lens, for example its curvature radius, but also the relative position of each lens to the other, such as the spacing and tilt.

The mechanical design of optics is not the only source of potential variation, though. The material properties of the glass used to carve the lenses are also subject to variations: Even with rigorous quality control, glass properties such as refractive index, absorption, transmittance, and dispersion (Abbe number) can vary slightly from batch to batch.

In most applications, these variations are negligible. However, particularly demanding applications work at the edge of what is physically possible to capture the smallest details. In these special cases, even within tolerances, variations may impair the precision of the imaging system. This can be the case in microscopy applications such as medical imaging or semiconductor inspection, or in very high-resolution outdoor imaging like aerial imaging.

Hyperspectral imaging, where images are captured at various wavelengths, is another challenging application. In these cases, even subtle magnification differences or focus shifts can affect measurement accuracy or image processing reliability.

Tailoring the Mechanics to the Glass Properties

Glass manufacturers deliver their glass with certified optical properties within the specified tolerances. When designing an optical system, precision optics manufacturers use various techniques to eliminate variations as much as possible in their mechanical design. For example, the symmetric design method consists of positioning similar lenses on both sides of the aperture, so variations compensate each other.

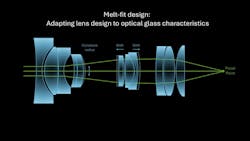

If these methods are not sufficient to achieve the required precision, the next escalation step is the so-called melt-fit process, which consists in tailoring the optical and mechanical design to the actual properties of the glass.

This process begins with the glass manufacturer providing exact measurements of the optical properties of a specific batch, going beyond standard tolerance ranges. These real-world values are then used to fine-tune the mechanical design of the optical system, such as adjusting lens spacing, to achieve the required precision.

This technology requires optical design capabilities and design software that models system performance based on both mechanical and material parameters.

Melt-fit also requires a close relationship between the optics and glass manufacturers as the measurement of glass properties is a high-precision task that requires substantial additional effort. For this reason, it is the last escalation step when all other optical design solutions fail to achieve the required precision.

Beyond Precision: Ensuring Consistency

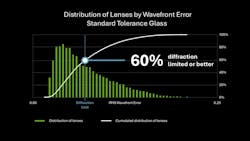

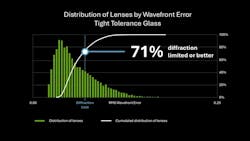

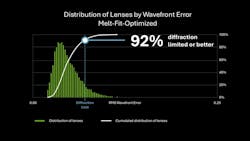

Today’s technologies allow precision optics manufacturers to achieve precision with conventional designs and manufacturing processes. When applications reach the limits of the technically feasible, melt-fit pushes the boundaries to achieve even better image quality.

But the absolute optical accuracy is nothing without consistency. High-precision optical systems must deliver the same level of performance from device to device at a level that may be incompatible with mechanical and material tolerances.

Melt-fit is a way for precision optics manufacturers to guarantee this consistency by tweaking the mechanical design depending on the optical properties of the glass batch they use. In that sense, it is not only useful for very specific and demanding custom designs but can also be used to ensure consistent performance for standard optics.

For example, the melt-fit approach can be used to optimize the precision of microscope systems to achieve consistent imaging performance across the full spectral range without refocusing and deliver the same level of performance on every device.

The precision of standard optical design and manufacturing fulfills the requirements of most applications. Advanced optical design using melt-fit allows manufacturers to provide even higher precision optics to demanding application fields and guarantee consistent performance from device to device.

About the Author

Thorsten Zwinger

Optical Design Engineer

Research and Development division at Excelitas

About the Author

Thorsten Zwinger

Thorsten Zwinger is an optical design engineer in the research and development division at Excelitas (Pittsburgh, PA, USA). He is responsible for the design, modeling, and optimization of optical systems. Currently, he is working on cutting-edge technologies to improve the performance and manufacturability of advanced optical systems.