Bringing a graphical user interface to Electron Micoscopy

Bringing a graphical user interface to Electron Micoscopy

By John Haystead, Contributing Editor

Of the two types of electron microscopes used in the electronics industry--scanning electron microscopes (SEMs) and transmission electron microscopes (TEMs)--SEMs are more common. A SEM operates like a television camera, scanning a beam of electrons across a sample with a focused probe, knocking electrons out of the sample. These electrons are then captured by detectors and are reconstructed into a digital micrograph of the sample. TEMs operate like an optical microscope in a fixed-probe mode. An electron beam is passed through a thin specimen in a controlled chamber, generating an image on a CCD detector.

SEMs are often used in quality control, for monitoring film coverage and particle counting, while TEMs, which require about four hours of specimen preparation, are primarily used as off-line, failure-analysis tools. "Real-time inspection is not yet the forte of electron microscopy," says John Hunt, director of research at Gatan (Pleasanton, CA). Unlike optical microscopy where images can be captured in 1/30 s, SEMs require between 1 and 10-20 µs per pixel for higher-quality images.

Although SEMs can scan an entire wafer for defects, it is more common for them to be used to examine a representative sample. So, although optical microscopes cannot resolve the level of feature detail many manufacturers need, SEMs are necessarily slower.

Acquisition, processing, and display

Gatan`s DigiScan electron-beam-acquisition and processing system for SEMs and TEMs generates images up to 8192 ¥ 8192 on a Macintosh host computer. SEM detectors read out different types of electron signals, such as very fast electrons (backscatter signal) for information about compositional changes and low-energy electrons (secondary signal) that provide information about topography.

According to Hunt, SEMs are not limited by their detector sensitivity, but rather statistical noise in the electron beam itself, which makes instrumentation noise insignificant. "It`s not uncommon to have a dynamic range in excess of 1 million to 10 million with 8 bits of information," he says. Information is collected from the data stream by integrating the data over time, with up to 5k A/D conversions at a single pixel. While resolutions of CCD cameras for optical microscopy are generally eight bits or less, the DigiScan`s resolution is greater than 16 bits/pixel.

In TEM applications, astronomy-grade CCD cameras sensitive to a single electron are used to collect image data. With video-rate signals, standard frame grabbers are used, but for astronomy-grade cameras, Gatan provides its own proprietary interface because there are no specific standards. Similarly, off-the-shelf frame grabbers do not support the data-handling techniques of SEMs, for which multiple detectors and unique frame sizes are often used.

More complex analysis

Although all users are concerned with high-fidelity images and good signal-to-noise ratios, they also want precise quantitative information such as percentages, locations, and timing of electrons. This information is then used for more complex analysis. Because each pixel can generate 1-, 2-, or 4-byte integers, floating-point integers up to eight bytes per pixel, and complex 16-byte/pixel data, DigiScan uses a scripting language similar to C that allows it to move between different data types. Software plug-ins support different imaging applications such as holography, diffraction analysis, and compositional analysis.

According to Hunt, today`s Macintosh platforms provide more than enough processing power. DigiScan software running on a Power PC 200-MHz 604E performs a 1k ¥ 1k floating-point Fourier transform in less than one second. According to Hunt, Gatan previously used array processors for this task, but "today`s general-purpose processors can perform such tasks just as fast. This allows us to preserve our code and design investment and concentrate on more system features rather than speed."

Likewise, I/O is not a challenge for the PCI bus, because information can be transferred to the host at 8 Mbyte/s. Gatan provides its own DMA to handle data flow with PCI plug-in boards. Software plug-ins support different microscopes.

Originally, Gatan chose Apple`s Macintosh because, at the time, it provided an operator-friendly environment for image processing. Today, the company is also moving to other platforms. But it must balance resources between product improvement and moving to different platforms.

Eventually, Hunt believes, SEMs will move to other manufacturing applications such as real-time inspection, and he definitely sees TEMs making their way onto the factory floor as geometries continue to shrink; but now, the requirement is not there.

Optical microscopes meet production throughput

Manufacturing inspection is clearly the entrenched niche of optical microscope systems. Although they do not compare to scanning electron microscopes (SEMs) or transmission electron microscopes (TEMs) in terms of resolution, they meet the flexibility and throughput requirements of the production floor. PC-based optical systems are also flexible enough to meet the electronics industry`s need to regularly update production. As opposed to large, totally automated centralized systems, individual PC-based inspection stations are time-effective in implementing modifications and their impact on the rest of the production floor.

According to Fred Houston, marketing manager at Sight Systems (Newbury Park, CA), system cost is a factor. The core of Sight Systems` optical micromeasurement system is its Vision Metrology Image Processor. The combination hardware/ software package is compatible with 486 or higher processors, Windows, or DOS, and includes a PCI-based, Falcon frame-grabber board from Univision Technologies (Billerica, MA). The Falcon, with on-board C31 DSP, replaces the PC`s standard video card and performs multilevel processing of position and measurement algorithms. Software-development tools and libraries, based on Microsoft`s Visual Basic, include an API for edge location, multiple object processing, and correlation functions.

"While our customers are not sophisticated about technology, they are extremely knowledgeable about cost per test, throughput, downtime, and mean time between assists," Houston says. This is one of the factors favoring PC-based processing, because higher-end VME, minis, and mainframes are not cost-effective in terms of cost per measurement. On the downside, adds Houston, "neither are users keen to invest in the development of new interfaces and software for future-generation PC processors such as the Pentium." In addition to taking advantage of current-generation processors, Houston observes, "speed increases have been due to moving from an EISA to PCI-based host."

But processing power is not the limiting factor in optical microscopy. Terry Coupe, Sight Systems software engineer, says the image processor is held back by the resolution limits of the imaging system itself. Optical microscopes are currently limited to about 1/4-µm resolution. Sight Systems` inspection systems generally operate at 100X magnification, and, although this can be increased to 200X or 250X, difractional limits of the system render little more data.

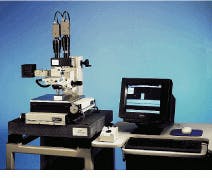

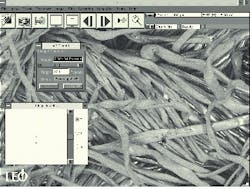

A Macintosh-based host brings a user-friendly interface to scanning and transmission electron microscopy.

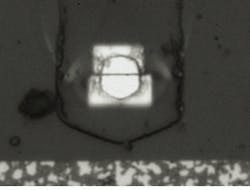

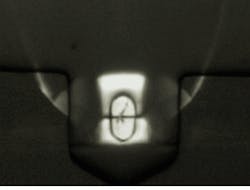

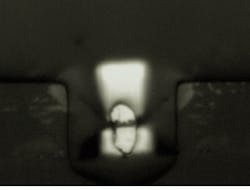

With shorter and shorter wavelength measurements needed for semiconductor masks and 400-A gap recording heads for hard drives, inspection requirements have begun to push beyond the limits of white-light microscopes. The VMIP system (above) inspects thin-film disk drive head; a good part (top left) is compared with a chipped (top right), damaged (bottom left), and dirty head (bottom right).

Windows brings software control to electron microscopy

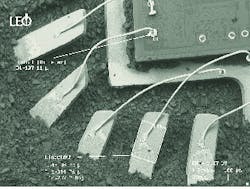

Image-processing functions of scanning electron microscopes (SEMs) and transmission electron microscopes (TEMs) are usually handled by custom-designed image-processing hardware. To provide a user-friendly interface, however, requires some kind of graphical user interface. For image-configuration management, storage, annotation, and manipulation functions, LEO Electron Microscopy (Thornwood, NY) chose Windows for its 435VP SEM workstation.

Capable of 15X to 300,000X magnification, the system is based on a Pentium 120-based PC. Software functions include macro generation, sequencing, stereoscopic imaging, motor-stage position control, and memory. Pseudocoloring and postprocessing of images are possible with user-defined look-up tables and third-party programs. The 435VP also can be linked to a LAN via an optional NIC.

Tim Maitland, LEO product manager, sees PC-controlled SEMs as a progression. "Software control allows multiple operators to maintain their own macro files and directories without having to reset mechanical knobs or paste warning notes on the machine." Networking also allows multiple users to have access to SEM imagery without using the instrument.

Currently, LEO`s software interface is a 16-bit Windows 3.11 application. "Although we could recompile the software for Windows 95," says Maitland, "we`ve chosen to maintain compatibility with the 16-bit drivers of the image-processor integrated circuits used by the scanning electron microscope."

Windows-based control added to an SEM workstation allows user to operate the system with pull-down menus and provides graphic overlay for image annotation.