Cameras check yarn-spool flaws

Nine cameras, frame grabbers, and PCs are networked into a vision-inspection system to check nylon-yarn packages for defects.

By Andrew Wilson,Editor

Over the years, the textile industry has made numerous attempts at automating the optical inspection of yarn spools for various defects. Because of the high number and variation of defects that can occur, manual inspection methods often miss (or subjectively pass) defects that can lead to costly production errors during the weaving, knitting, and dyeing stages of textile production. Despite these limitations, even partially successful attempts to automate the process have been abandoned because the purpose of fully eliminating the human inspection process could not be realized.

In the production of textiles, synthetic yarns consisting primarily of polyester, nylon, and acrylic materials are processed by melting the polymer and extruding the melt through extrusion dies, known as spinnerets. As filaments emerge from the holes in the spinneret, the liquid polymer first converts to a rubbery state and then solidifies. After the yarn solidifies, it is wound onto spools at speeds of up to 6000 m/min and then texturized by heating and twisting at speeds exceeding 1000 m/min.

Sapona Manufacturing Co. (Cedar Falls, NC) has been manufacturing textile products since 1836. It is now the second-largest producer of textured nylon yarn in the United States, manufacturing up to 10 million pounds per year. In 2001, Dean Lail, president of Sapona, called on Line Tech Industries (Brooklyn, NY) to develop a vision-inspection system that could detect yarn-spool defects.

The system needed to inspect all types of textured-nylon-yarn packages, including fine- denier, heavy-denier, low-air, high-air, oil, and low-oil packages. In addition, the system was required to detect such textile defects as broken filaments, snags, taper angles, bulges, and winding length.

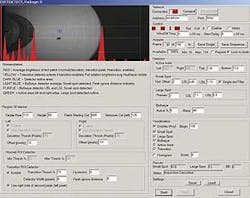

Line Tech Industries built a modular yarn-inspection system—Package Inspector XL (PIXL)—using off-the-shelf lighting, cameras, and frame grabbers networked into an array of PC-based systems (see Fig. 1).

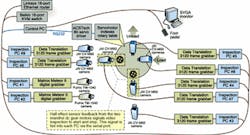

System operationDuring system operation, an operator loads the spindle of yarn onto a mandrel at the loading stage. Next, the operator actuates a main turntable using a foot pedal that, under direction of the control PC, indexes the rotary table by 90° using a servomotor controlled by a stand-alone SB1391 motion-control module from Technology 80 (Minneapolis, MN).After the table has been indexed by 90°, the spool of yarn enters the first inspection station. Here, power is applied to the mandrel that rotates the spindle for initial inspection. The motion controller then sends a handshake signal back to the control PC that the table has been indexed. Each independent PC in the inspection system then starts capturing data from each of the imaging subsystems (see Fig. 2).

At the first inspection station, it is necessary to inspect the rotating spool for overthrown ends at the top and bottom of the bobbin. "To accomplish this at low cost," says Tobias Jackson, president of Line Tech Industries, "two CV-M50 monochrome RS-170 cameras from JAI America (Laguna Hills, CA) are positioned to image the top and bottom of each bobbin. Using two separate 3120 PCI-based frame-grabber boards from Data Translation (Marlboro, MA), both images are digitized into two separate PCs for inspection of the captured images.

At the same time images of the top and bottom of the bobbin are being inspected, it is necessary to inspect the entire surface of the spool of yarn for broken yarn filaments that could be as small as 1/32 in. long. "To do so," says Jackson, "requires that an extremely bright light to illuminate the tiny filaments." Jackson and his colleagues installed two 150-W metal-halide lamps to light the top and sides of the spool. With this lighting in place, two TM-1040 1k X 1k, 30-frame/s CCD cameras from Pulnix (Sunnyvale, CA) digitize the right and left hand sides of the spool.

"Digitizing high-resolution images from the two TM-1040 cameras," says Jackson, "means that the Meteor II board from Matrox (Dorval, Quebec, Canada) must digitize the RS-644 signals from each of the two cameras. The resultant images contribute to inspecting the complete surface of the yarn spool (see Fig. 3).

Round and roundAfter the initial inspection, one operator indexes the turntable again using the foot pedal, while another operator unloads the final inspected part from the off-load station. The first operator places a new spool on the empty mandrel and indexes the turntable once again. At this point, the spool that has passed the initial inspection is moved to the second inspection station. Therefore, while the first inspection station is examining a spool of yarn for broken filaments, overthrown ends, and transfer tails, the second inspection station is locating dirt and winding defects at the top and bottom of the bobbin, as well as the ply of the yarn.Although the second inspection station is similar in mechanical design to the first station, no high-speed inspection is required. Therefore, the complete inspection process can be accomplished using a network of CV-M50 cameras and DT 3120 frame-grabber boards.

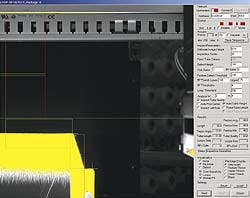

"To detect dirt and oil that may be present on the spools of yarn," says Jackson, "metal-halide lighting could not be used." Instead, LineTech Industries opted for a combination of black light and filtered red light to illuminate the spool. By illuminating the spool of yarn with black light from above, captured images can easily detect the presence of dirt while the spool is rotating (see Fig. 4). And, by illuminating each end of the spool with filtered red light, the two horizontally located CV-M50 cameras can detect the presence of dirt and oil.

Finally, to inspect the ply and knot interval of the yarn, it is necessary to run off about 5 ft of yarn. To do this, the operator places the end of the yarn in a special receptacle as it is loaded onto the inspection station. However, it is not until the spool of yarn reaches the second station that the yarn is pulled by a motor control system and is viewed using another CV-M50 camera. Here, under control of another networked PC, the system can monitor such factors as the prerun time and run-out time and measure the smoothness and contiguousness of the thread. After final inspection, the operator indexes the table by another 90° using the foot pedal and loads the inspected spool into a carton for shipping to the weaver.

Software designDoing all programming in C++, Line Tech built a total of five stacked algorithms to detect a total of 30 defects and measurements in real time. "With the goal of 'the simpler, the better,' all the lighting techniques are matched to allow for fast region-of-interest detection subalgorithms," says Jackson. Using the drivers for the Matrox and Data Translation frame-grabber boards, LineTech used Microsoft C++ development software to develop a series of individual image-processing blocks with each performing a specific function on each of the nine PCs."By writing the algorithms as C++ code," says Jackson, "each algorithm could run in native mode on each PC." Preferring not to use Data Translation DT Foundry or Matrox Imaging Library (MIL), Line Tech instead developed a system that is completely customized and proprietary and did not depend on any third-party vendor's image-processing code. "By eliminating the constraints of third-party function libraries, we were able to customize the algorithms to match data-capture rates to enable real-time image processing," he says.

In the current design of the system, a number of independent PC-based imaging stations are networked over an Ethernet. This design eliminates many potential problems and difficulties that would have occurred in multiplexed systems. If, for example, cameras had been multiplexed into single frame grabbers, Jackson and his colleagues would have had to optimize the system to account for any timing problems that might have occurred. In the PIXL system, however, the low cost of high-speed PCs and image-processing peripherals means that stand-alone image-processing algorithms are more easily implemented on discrete, networked workstations.