Vision system checks keyboards

Imperfections in keyboards for all sorts of electronic devices include surface flaws in the lettering, scratches, misplaced markings, and foreign material. Inspecting the keyboards for defects is challenging because it is difficult to locate and distinguish flaws from the surface texture, the range and size of surface flaws is large, suitable illumination is not easy to install under factory operating conditions, and a variety of different color letters and numerals may be used.

To combat these issues, Second2None Machine Vision Systems (Shenzhen, China; www.visiondragon.com) developed a two-CCD camera system in which illumination is provided by focused LED lighting. Ding Shaohua, managing director of Second2None, says he uses the Locator tool in HexSight software from LMI Technologies (Delta, BC, Canada; www.lmitechnologies.com) to accurately locate and image the keyboard. The image is then processed by geometric pattern matching to detect defects.

IR light visualizes nanoscale strain fields

A team of researchers from CIC nanoGUNE (San Sebastian, Spain; www.nanogune.eu) and the Max Planck Institutes of Biochemistry and Plasma Physics (Munich, Germany; www.biochem.mpg.de) have performed non-invasive and nanoscale resolved infrared mapping of strain fields in semiconductors. The method opens new avenues for analyzing mechanical properties of high-performance materials or for contact-free mapping of local conductivity in strain-engineered electronic devices.

The team has provided the first experimental evidence that scattering-type scanning near-field optical microscopy (s-SNOM) is capable of mapping local strain and cracks of nanoscale dimensions. The technique makes use of extreme light concentration at the sharp tip of an atomic force microscope, yielding nanoscale resolved images at visible, infrared, and terahertz frequencies. This was demonstrated by pressing a sharp diamond tip into the surface of a silicon carbide crystal. With the near-field microscope the researchers were able to visualize the nanoscopic strain field around the depression and the generation of nanocracks. Applications could include detection of nanocracks before they reach critical dimensions in ceramics or MEMS, and the study of crack propagation.

Object tracking uses GPUs

Consumer graphics processing units (GPUs) have experienced an extraordinary evolution in both computing performance and programmability, leading to greater use of the GPU for non-rendering applications. Now, Bryson Payne, assistant professor of computer science at North Georgia College & State University, and his colleagues have developed a real-time object tracking algorithm, based on the hybridization of particle filtering (PF) and a multiscale local search (MSLS) algorithm for both CPU and GPU architectures.

The developed system provides successful results in precise tracking of single and multiple targets in monocular video, operating in real time at 70 frames/s for 640 × 480-pixel video resolutions on the GPU, up to 1100% faster than the CPU version of the algorithm. For more information, go to: www.gavab.es/capo/msls_pf/.

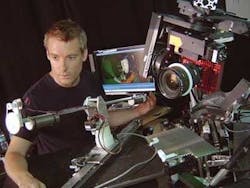

Machine vision enables stop-motion animation

Coraline, an animated movie from Laika (Portland, OR, USA; www.laika.com), is reportedly the first major stop-motion feature to be shot with industrial machine-vision cameras, as well as the first to be shot in stereoscopic 3-D. Instead of shooting on film, director of photography Pete Kozachik acquired the movie’s frame-by-frame footage using roughly three dozen cooled, 11-Mpixel Megaplus cameras from Princeton Instruments (Trenton, NJ, USA; www.princetoninstruments.com).

Kozachik says the industrial cameras offer advantages over previously employed techniques that relied on film, video frame grabbers, and prosumer digital SLRs. In addition to resolution and color reproduction, the flexible programmability and rugged mechanical housing of the cameras are important for the application. Thermoelectric cooling is critical too, as dark current has to be minimized during the relatively long exposure times. Coraline is a tale about a curious girl who unlocks a mysterious door in her family’s new home and enters into an adventure in a parallel reality.

Lasers and video cameras detect explosives

A new device that can identify explosive particles not visible to the eye on people, clothing, and luggage is being developed by engineers at Loughborough University (Loughborough, UK; www.lboro.ac.uk). The Explosive Residue Detection system can remotely scan crowded areas such as airports and train stations, alerting an operator if it detects traces of explosives. Developed by John Tyrer from the University’s Wolfson School of Mechanical and Manufacturing Engineering, along with colleagues from the Department of Chemistry, the device is currently undergoing field trials in the UK.

The system combines pulsed lasers and video camera techniques to produce a large-area, fluorescent, lifetime imaging system. By controlling the laser timing and optical filters, this allows direct imaging of explosive residue. Once the explosive residue is detected, the system activates automatically and alerts an operator. It does not rely on people watching a monitor screen and, unlike sniffer dogs that operate by detecting particles present in the air, this system can be very specific and accurate.