LED lighting vendors diversify their product offerings

With the advent of UV and IR-based LEDs, manufacturers can offer a broader range of products that span a wider illumination spectrum.

In the past, LED-based machine vision lighting was limited to the visible spectrum. Now, LED vendors are offering devices that encompass the ultraviolet (UV), narrow-band and broad-band visible and infrared (IR) spectrum. Using these devices, manufacturers of machine vision lighting can offer products that can be employed in niche UV and IR systems and multi-color, multispectral and hyperspectral applications. Indeed, according to Yole Développement (Lyon-Villeurbanne, France; www.yole.fr), since these require higher levels of design expertise, LED module manufacturers are betting that systems integrators will not have the competencies required (see “LED Lighting Module Technology, Industry and Market Trends 2017,” http://bit.ly/VSD-YLED).

In recent years, LED manufacturers have introduced devices that emit wavelengths in the UV spectrum. These are generally specified in the 100-400nm range, which is further sub-divided into UVC (100-280 nm), UVB (280-315nm) and UVA (315-400nm). In the past UVC radiation was produced by low and medium pressure Mercury vapor lamps for air and water purification and food pathogen reduction systems.

Figure 1: By capturing an image of a CD jewel case in both the visible spectrum (left) and under 365-nm UV dark field lighting (right) with the camera positioned at a 45° angle reveals the scratches present on the surface.

Today, a number of LED manufacturers, including Nitride Semiconductors (Tokushima, Japan; www.nitride.co.jp), Toyoda Gosei (Aichi, Japan; www.toyoda-gosei.com) and LG Innotek (Seoul, South Korea; www.led.lginnotek.com) are introducing LEDs to perform similar tasks. Such devices eliminate the slow warm-up times and high energy costs associated with Mercury vapor lamps. As an example, the LEUVA66H70HF00 in LG Innotek’s 6060 series produces a wavelength of 278nm and an optical output power of 70mW.

Even though this optical output power is significantly less than mercury vapor lamps, Joo-Yeon Shina and his colleagues at the Seoul National University (Seoul, Republic of Korea; www.useoul.edu) have shown that UVC LEDs can be used effectively to control foodborne pathogens (http://bit.ly/VSD-DUV).

UV in machine vision

While direct UVC illumination is used in water and food treatment systems, machine vision systems most commonly employ frequencies in the UVB and UVA spectrum. Here, either reflected or fluorescence-based systems are employed. In the former, the surface of an object is illuminated with UV light which is then scattered or reflected towards a camera sensitive to UV.

Similarly in UV fluorescence imaging, objects are illuminated with UV light. However, in this case the object absorbs the UV radiation and re-radiates a longer diffuse wavelength. Here, the difference in wavelength between positions of the band maxima of the absorption and emission spectra are known as Stokes shift (see “Applying ultraviolet lighting in machine vision applications,” Vision Systems Design, September 2017; http://bit.ly/VSD-UVL).

One of the most commonly-used applications for reflected UV imaging is the detection of scratches on the surface of glass objects or lenses, according to Universe Kogaku (Oyster Bay, NY, USA; www.universeoptics.com) because of its shorter-reflected UV wavelength. Other applications include surface-contamination detection, because UV light tends to be absorbed by organic materials such as oil or grease. As Austin Richards, Chief Technology Officer at Oculus Photonics (Goleta, CA, USA; www.ultravioletcameras.com) points out, scratches may only be visible when visible light strikes at a very oblique angle. In contrast, in a UV image taken at 365 nm, the scratches can be easily visualized (see “UV imaging opens new applications,” Vision Systems Design, July 2006; http://bit.ly/VSD-UVI). In this case, a CD jewel case is imaged in both visible (left) and 365-nm UV dark field lighting (right) with the camera positioned at a 45° angle (Figure 1).

While reflected UV imaging is often used for defect and surface contamination detection, UV fluorescence applications include fraud detection, fruit inspection and the analysis of paintings. To detect whether paper currency is authentic, for example, illuminating banknotes using a UV light at 365nm will result in fluorescence of the embedded stripe. According to the United States Treasury, this results in blue, green and red light being emitted when $5, $20 and $100 bills are subject to the illumination (Figure 2). In this case, the banknotes were illuminated with Mini UV Lamps from Mineralogical Research Company (San Jose, CA, USA; www.minresco.com).

Figure 2: To detect whether paper currency is authentic, illuminating banknotes using a UV light at 365nm will result in fluorescence of the embedded stripe. According to the United States Treasury, this results in blue, green and red light being emitted when $5, $20 and $100 bills are subject to this UV illumination.

Similarly, UV fluorescence can be used as an illuminant in fruit inspection systems. One customer of UV Light Technology (Birmingham, UK, www.uv-light.co.uk), for example, has used its UV lights to inspect oranges for signs of visible contamination and bruising. Tests using several of UV Light Technology’s OptiMinUV backlight proved that a UV-A illuminant would improve the inspection process due to the enhanced visibility of contamination and bruising (Figure 3). This is because bruised or damaged fruit releases enzymes which fluoresce under UV illumination.

Figure 3: UV fluorescence with a UV-A illuminant can be used in fruit inspection systems such as inspecting oranges for signs of visible contamination and bruising. This is because bruised or damaged fruit releases enzymes which fluoresce under UV illumination.

From UV to RGB

Just as UV LED illumination products are available in a number of different peak wavelengths, so are those that cover the visible spectrum. Here again, the bandwidth of LEDs that cover the blue, green and red spectra is narrow. In many machine vision applications, however, such LEDs can be used to increase the contrast of features within images.

Choosing which LED lighting for any particular machine vision application depends on both the wavelength of light that is chosen and the particular configuration of lighting product. One of the ways to determine which individual LED frequency is used, is to use a color wheel, as Daryl Martin of Advanced illumination (Rochester, VT, USA; www.advancedillumination.com) points out in his paper “A practical guide to machine vision lighting” (http://bit.ly/VSD-DMMV).

Objects that are white, for example, appear red if illuminated with a red LED since white consists of many colors. However, when a red object is subjected to blue light, it appears dark because red absorbs the blue light. Using this concept, the contrast of features within an image of a particular color can be increased or decreased as required.

However, it is not just the frequency of light that must be considered when deciding on how to increase the contrast of captured images. Choosing the correct lighting technique is equally as important. These include setups that can include full or partial brightfield, darkfield, diffuse dome, axial diffuse, flat diffuse and backlighting configurations (Figure 4).

Figure 4: Choosing the correct lighting technique is important and includes setups such as full or partial brightfield, darkfield, diffuse dome, axial diffuse, flat diffuse and backlighting configurations.

To understand how these configurations can impact the design of a vision system, application notes are available from may lighting vendors. Among these are “Precise Lighting for Machine Vision” (http://bit.ly/VSD-NERL) from Omron Microscan (Renton, WA, USA; www.microscan.com), “Applications for Telecentric Lighting” (http://bit.ly/VSD-TCL) from Vision & Control (Suhl, Germany; www.vision-control.com), “Vision System Peripheral Equipment Catalog” (http://bit.ly/VSD-KEY) from Keyence (Itasca, IL, USA; www.keyence.com) and “The Imaging and Vision Handbook” (http://bit.ly/VSD-IVH) from Stemmer Imaging (Puchheim, Germany; www.stemmer-imaging.com). Using these examples, systems integrators can better understand the correct configuration and wavelength to choose for a particular application.

In modern machine vision illumination systems, high brightness is critical in achieving consistent performance and reducing exposure time to allow for higher speed image acquisition. However, increasing brightness using high-power bar lights generally will result in ‘hot spots’ and saturation across the camera’s Field of View (FOV). Typically, the exposure time and brightness must be reduced to compensate for this, or the illumination size must be much greater than the size of the FOV. TPL Vision (La Chevrolière; France; www.tpl-vision.fr/en) has recently been honored with a Silver-level Vision Systems Design 2018 Innovators Award for its new EBAR CURVE that was designed to address such problems. According to the company, the patent-pending design produces parabolic brightness output that maintains a uniform illumination while reducing the number of LEDs used in the lighting configuration. Users can also balance brightness and homogeneity using a lockable keyboard to fine tune results. One of the main highlights of the new product, according to the company, is the fact that the machine vision bar light will illuminate the entire surface of the field of view, thus enabling users to get a bar light with the same dimensions as the FOV.

Companies mentioned

Advanced illumination

Rochester, VT, USA

www.advancedillumination.com

Büchner Lichtsysteme

Welden, Germany

www.buechner-lichtsysteme.de

CCS America

Burlington, MA, USA

www.ccsamerica.com

FiberTech Optica

Kitchener, ON, Canada

www.fibertech-optica.com

Keyence

Itasca, IL, USA

www.keyence.com

LG Innotek

Seoul, South Korea

www.led.lginnotek.com

Macquarie University

Sydney, Australia

www.mq.edu.au

Metaphase Lighting Technologies

Bristol, PA, USA

www.metaphase-tech.com

Mineralogical Research Company

San Jose, CA, USA

www.minresco.com

Moritex

Saitama, Japan

www.moritex.com

Nitride Semiconductors

Tokushima, Japan

www.nitride.co.jp

Oculus Photonics

Goleta, CA, USA

www.ultravioletcameras.com

Prizmatix Givat-Shmuel, Israel

www.prizmatix.com

ProPhotonix

Salem, NH, USA

Yole Développement

Lyon-Villeurbanne, France

www.yole.fr

Toyoda Gosei

Aichi, Japan

Seoul National University

Seoul, Republic of Korea

www.useoul.edu

Smart Vision Lights

Muskegon, IL, USA

www.smartvisionlights.com

Spectrum Illumination

Montague, MI, USA

www.spectrumillumination.com

Stemmer Imaging

Puchheim, Germany

www.stemmer-imaging.com

TPL Vision

La Chevrolière; France

www.tpl-vision.fr/en

Universe Kogaku

Oyster Bay, NY, USA

www.universeoptics.com

UV Light Technology

Birmingham, England

www.uv-light.co.uk

VS Technology

Tokyo, Japan

www.vst.co.jp

For more information about machine vision lighting companies and products, visit Vision Systems Design’s Buyer’s Guide buyersguide.vision-systems.com

Multiple wavelengths

In some applications, single wavelength red, green or blue LEDs in ring lights, line lights, spotlights, dome lights and flat panels will not suffice. In applications where the contrast of different-colored products must be highlighted on the same production line, lighting products can employ LEDs of different wavelengths that can be switched as required.

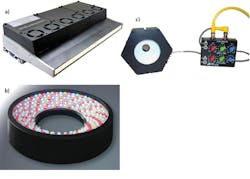

For line-scan applications, for example, ProPhotonix (Salem, NH, USA; www.prophotonix.com) has developed its COBRA RGB LED line light. Controlled over Ethernet, systems integrators can then remotely tailor the color of the illumination. The company’s latest product, the COBRA MultiSpec LED, another Silver-level Vision Systems Design 2018 Innovators Awards honoree, can be configured with two to 12 wavelengths of LEDs, ranging from 365–1500nm (Figure 5a).

RGB ring lights are also available from a number of vendors. Once such illuminator, the MDRL-CRGB56-3CH MG-Wave from Moritex (Saitama, Japan; www.moritex.com) is arranged with RGB LEDs capable of individual and mixed-color control. These can be used in a number of different configurations to provide direct front illumination, diffuse bright-field and diffuse dark-field illumination (Figure 5b).

Where curved, specular surfaces need to be illuminated at different wavelengths, RGB dome lights are the optimum choice. Such a dome light, the DADL75 dual-axis RGB LED light from Smart Vision Lights (Muskegon, IL, www.smartvisionlights.com) is designed as a multi-color inspection light with a built in individual on-axis and off-axis intensity control and can be used in applications that require variable intensities with multiple-color illumination (Figure 5c).

Figure 5: In applications where the contrast of different colored products must be highlighted on the same production line, lighting products can employ RGB LEDs that can be switched as required. These include (a) the COBRA RGB LED line light from ProPhotonix, (b) the MDRL-CRGB56-3CH MG-Wave ring light from Moritex and (c) the DADL75 dual-axis RGB dome light from Smart Vision Lights.

Multispectral vs hyperspectral

Lighting products that employ between three and 10 fairly broad wavelength bands such as red (R), green (G), blue (B), UV and near-infra-red (NIR) LEDs can be termed multispectral illuminators. In many niche hyperspectral applications such as epifluorescence microscopy where both the illuminated and emitted light travels through the same objective lens, however, multiple wavelengths of light ranging from UV to visible are required.

In these applications, Mercury-based lamps are often used. However these suffer from short lifespans and produce unstable power output over time. To replace such lamps with LEDs that produce sufficient light output over the UV and visible spectrum is a key requirement, according to Kashif Islam of Macquarie University (Sydney, Australia; www.mq.edu.au).

In his paper “Multi-LED light source for hyperspectral imaging,” (http://bit.ly/VSD-OSA), Islam describes the design of an LED light source that can be used as a replacement for Mercury-based lamps in hyperspectral imaging systems. Optically-coupled white light sources that use multiple LEDs of different frequencies have been developed commercially for such applications by such companies as Prizmatix (Givat-Shmuel, Israel; www.prizmatix.com) with its OptiBlocks family and FiberTech Optica (Kitchener, ON, Canada; www.fibertech-optica.com) with its fiber-coupled multi-wavelength LED light source.

The challenge in creating LED hyperspectral illumination systems, is overcoming the narrow spectral bands of traditional LED soures which, for example, may require 10-16 discrete LEDs to cover the 400-1000nm spectral band. Metaphase Lighting Technologies (Bristol, PA, USA; www.metaphase-tech.com) has recently been honored with a Gold-level Vision Systems Design 2018 Innovators Award for its new line of hyperspectral LED illumination products. The company worked closely with LED manufacturers to create custom broadband blue and white LEDs. These innovations, paired with 3 NIR LEDs and Metaphase’s proprietary optics, provide yet another option for such applications.

Longer wavelengths

Just as UV lighting can reveal defects unseen by visible light, the use of near infrared (NIR) illumination sources of between 850-1000nm can also used. With a longer wavelength than visible light, NIR energy penetrates certain materials and can be used, for example, in applications to reveal the fill levels in packaged plastic containers (Figure 6).

Figure 6: With a longer wavelength than visible light, NIR energy penetrates certain materials and can be used, for example, in applications to reveal the fill levels in packaged plastic containers or eliminate the print on products.

Here again, a number of companies manufacture a range of ring lights, line lights, dome lights and coaxial lights that feature NIR LEDs. These include Büchner Lichtsysteme (Welden, Germany, www.buechner-lichtsysteme.de), VS Technology (Tokyo, Japan, www.vst.co.jp) and Spectrum Illumination (Montague, MI, USA; www.spectrumillumination.com).

To show the effects NIR lighting can have when illuminating food containers, confectionery and stitched leather products, CCS America (Burlington, MA, USA; www.ccsamerica.com) has produced a brochure that shows how its flat-panel, dome and ring lights can be used (http://bit.ly/VSD-ILED).

Today, many lighting products are offered in single wavelengths covering the UV, red, green, blue or IR spectrum. When the application is well-understood and not subject to change, such products are the least expensive. In other situations, where multi-colored products may need to be inspected, the use of RGB illuminators may be more cost-effective. While few machine vision applications demand the use of UV, RGB and IR illumination in a single package, lighting manufacturers can now use off-the-shelf LEDs to develop products that meet a range of applications that demand more than single wavelength illumination.

About the Author

Andy Wilson

Founding Editor

Founding editor of Vision Systems Design. Industry authority and author of thousands of technical articles on image processing, machine vision, and computer science.

B.Sc., Warwick University

Tel: 603-891-9115

Fax: 603-891-9297