Automated visual inspection and defects classification system

Example of surface inspection

BitRefine Heads works with almost all kinds of defects. Here we look at one of typical examples — visual surface inspection. If we take industrial materials, the defects can be crazing, scratches, pitted surfaces, patches or inclusions. Recognition system can reliably detect and classify them all.

The “heart”, or better to say the “brain” of recognition system is specialized neural module, that is loaded into BitRefine Heads. This module can equally well recognize target defects regardless of angles, backgrounds, shapes of product itself, etc. Similar to human’s brain this neural module works well at wide range of conditions and is immune to most of environmental interference.

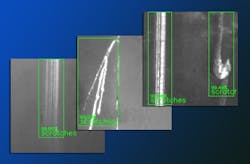

Compare these images: all of them show scratches. Despite the difference in angles, shapes and sizes, system recognizes them all as a “scratch”.

Here are examples for stains:

And here are patches:

Localization increases efficiency and reduces costs

BitRefine Heads platform allows working with large images containing numerous smaller defects, such as single high-res image of large steel sheet, or a single image of multiple rows of products. System recognizes defect as well as its location and sends not a general alert, but a signal to a particular row, where a defect was detected. This means that instead of installing a camera per row, we can have single camera covering at once big part of conveyor.

Scale up intelligence

Multi-purpose recognition system allows solving not just single task of inspecting objects for various defects. This system allows collecting all sorts of information, converting it into analytics, automation or real-time alerting. For example, adding human recognition neural module will allow tracking movements of people that work around conveyor, improving safety or collecting statistical data.

Data science

Many large corporation have already started process of their transformation into data-centric companies. Collecting all sorts of data in combination with machine learning tools allow companies significantly boost their efficiency. In this sense, video recognition platform is not just a part of production automation, but also important source of data that is to be integrated together with all other data into corporate data lake.

Bitrefine group is a data science company that solves clients’ challenges in the field of machine learning and computer vision. If your’re interested in further info regarding computer vision and neural networks please, visit us at https://heads.bitrefine.group or leave a “Hello” at [email protected]