3D Ultrasonic Sensing Technology Could Boost Robot Safety Performance

What You Will Learn

- ADAR technology uses sound waves instead of light, providing obstacle detection in dust, darkness, and complex environments.

- Software beamforming eliminates the need for moving parts, enabling real-time 3D scanning and obstacle tracking.

- Compared to LiDAR, ultrasonic sensors offer wider field of view, lower cost, lighter weight, and better performance in challenging conditions.

- The future probably lies in sensor packages—a multiplicity of sensors, including cameras, combined in different ways for different applications and environments.

To realize a future where humans and robots seamlessly share dynamic spaces, the safety capabilities and cost of robot sensor packages will be critical. Costly solutions will hamper widespread adoption, while sensors that don’t meet recognized safety standards and requirements won’t succeed in the market.

The latest ultrasonic sensors with 3D capabilities and powered by tiny high-performance ultrasonic emitters and receivers, offer a potential solution.

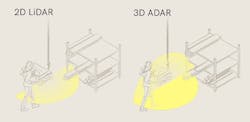

For decades, safety in robotics has been managed in two dimensions. Planar protective fields, typically defined by laser scanners or simple 1D ultrasonic sensors, have been sufficient for stationary or slow-moving machines. But as robots become faster, more mobile, and increasingly share space with people, this 2D paradigm begins to break down.

A new generation of ultrasonic sensors promise improved obstacle detection performance versus 2D LiDAR and at a lower cost point. These sensors can be integrated into sensing devices, simplifying robot design.

If these claims are correct, robot builders, especially those tasked with providing robot sensor packages with depth perception and obstacle detection capabilities on autonomous mobile robots (AMRs) have a new tool for their toolkit that can reduce the cost of robot safety sensor packages while improving obstacle detection performance.

Meet ADAR

Acoustic detection and ranging (ADAR) is an emerging technology. Unlike the prevailing electromagnetic wave solutions (LiDAR and cameras), ADAR can provide robust performance in challenging environments such as dust and varying light conditions, resulting in reliable and accurate 3D depth sensing.

Related: Robots and Cobots: A Peer-to-Peer FAQ

As a result, autonomous mobile robots go from a narrow in-plane view (with 2D LiDAR) to an all-around view with ADAS. This increases the safety zone and enables human interaction.

ADAR’s combination of safe 3D object detection, full vertical views, and low computational requirements enables safer robot movement, reducing risk without adding complexity or cost to the machine.

How Does ADAR Work?

ADAR has similarities to RADAR, SONAR and even LiDAR, but it uses sound waves instead of light.

ADAR emits sound waves that are reflected by nearby objects and subsequently detected by a sensor. While technologies like LiDAR typically rely on a rotating laser beam to scan the environment, the ADAR technology built into these new 3D ultrasonic sensors can cover a full hemisphere (180° x 180°) and without any moving parts. This is made possible by advancements in transducer design.

The Tyrannical λ/2 Rule

For ultrasonic arrays to accurately determine target positions, the distance between adjacent elements must be less than or equal to half the wavelength of the transmitted sound. Known as the λ/2 rule, this spacing helps to avoid position ambiguity. Spacing that goes above the λ/2 rule is troublesome since more grating lobes are created.

Related: Zalando Incorporating Mobile Robots into Logistics Applications

In water, where sound travels at 1500 m/s, the λ/2 rule requires elements to be spaced no more than 9.4 mm apart for 80 kHz operation—a relatively easy task with the available technology. However, in air, where sound travels at 343 m/s, the same rule demands that elements be spaced no more than 2.1 mm apart for 80 kHz operation. Manufacturing efficient transducers smaller than 2.1 mm was beyond reach, until recent developments in transducer design.

MEMS the Word

MEMS (MicroElectroMechanical System) technology is used to fabricate miniaturized mechanical systems where the main material is silicon. MEMS can be used to scale down ultrasound transducers to a MUT (Micromachined Ultrasonic Transducer). One way of doing this is by a piezoelectric material addon to MEMS (piezoMEMS), resulting in a PMUT (Piezoelectric Micromachined Ultrasonic Transducer).

The researchers behind the new 3D ultrasonic sensor developed PMUTs that demonstrate comparable sound pressure with commercial bulk transducers, in air, at a fraction of the size. For example, a 3x3 100 kHz PMUT array has the same footprint as the smallest commercial transducer. Moreover, PMUTs can be designed to transmit at higher frequencies than 40 kHz, which have become the standard for air-based ultrasound. This is beneficial as the angular resolution is fundamentally dependent on the frequency.

3D Beamforming

Detecting objects in front of a PMUT is one thing, but scanning a 3D volume and achieving real-time operation requires software beamforming.

Related: Depth Cameras Can Fill LiDAR's Autonomous Vehicle Blind Spots—Here's How

Beamforming allows energy to be sent or received from a specific direction. Traditionally, beamforming is achieved using mechanical means. Radars use rotating antennas, radio telescopes physically rotate to scan the sky, and medical ultrasound probes use tiny motors to steer an ultrasonic element.

The rise of digital signal processing makes it possible to beamform without moving parts, through manipulation of the signals received by each element in the array. Recent advances in hardware performance and signal processing make software beamforming convenient and effective for real-time applications like obstacle detection.

Conventional Sensor Limitations

Conventional ultrasonic range sensors have been around for over 30 years and are extremely cheap. So, why would a mobile robot builder want to consider 3D ultrasonic sensing?

Traditional ultrasonic range sensors suffer from "tunnel vision." They have a narrow field of view (FOV), with a typical range of 10º to 45º, which limits their ability to provide effective object detection.

Moreover, traditional ultrasonic sensors have a single element, meaning they cannot focus their energy on a specific region of space. This restricts them to tracking one object at a time. It also makes them susceptible to false readings caused by echoes and background noise. Without the ability to steer the beam, echoes coming from reflective surfaces are simply undetectable, unless they arrive from very specific angles.

The new 3D ultrasonic sensor addresses these limitations. It has a wide FOV covering 180º x 180º and a fully steerable, multi-element array, enabling it to provide detection capabilities across a broader range of environments, including precise object tracking in complex and cluttered spaces.

Weaknesses of LiDAR for Obstacle Detection

LiDAR has well-known shortcomings when it comes to effective obstacle detection. LiDAR has a limited FOV and can only sense a small, two-dimensional slice of the environment around a robot. 2D LiDAR only tells part of the story.

Related: SwRI Develops Off-Road Autonomous System with Passive Sensors

Typically mounted on AMRs at a height of around 20 cm (7.9 in), 2D safety LiDAR won’t detect objects 10 cm above the floor. It won’t detect objects hanging from the roof, or items sticking out from walls or shelves. Moreover, different lighting conditions create challenges for LiDAR, as do transparent surfaces.

Meanwhile, the latest generation of ultrasonic sensors based on ADAR technology provides a 360-degree (180 v 180) view of the scene up to a distance of five meters (16.4 ft). Weighing less than 200 grams, the sensor can detect and track objects larger than 3 cm, despite its compact form factor (9 x 9 x 2.5 cm) and power consumption of less than 5 watts.

All this means that the new sensor can be used to create a 3D safety shield for obstacle detection around any mobile robot. That’s an improvement in performance and at a lower cost than LiDAR.

Does this mean ADAR could replace LiDAR? It could replace 2D safety LiDAR for obstacle detection and depth perception, but the future lies in sensor packages—a multiplicity of sensors, including cameras, combined in different ways for different applications and environments.

Related: LiDAR Hits the Road

Rather than a replacing LiDAR, the new sensor is an addition to robot builders’ toolkits that they can deploy to enhance safety while at the same time potentially reducing costs, for themselves and ultimately for end users.

About the Author

Ole Marius Hoel Rindal

Ole Marius Hoel Rindal, PhD, is co-founder of Sonair (Oslo, Norway) and a lecturer at the University of Oslo (Norway) on ultrasound imaging. Sonair develops and markets a 3D ultrasonic sensor designed for autonomous mobile robots.