REAL-TIME web-inspection system FINDS STEEL DEFECTS

REAL-TIME web-inspection system FINDS STEEL DEFECTS

By R. Winn Hardin, Contributing Editor

High-speed web inspection remains among the most challenging machine-vision applications to design and operate. A few years ago, systems integrators would not have considered the development of a host-based system to inspect, for example, steel rolls moving at 600 to 3000 ft/min on a factory floor.

Despite the difficulties inherent in such a vision application, engineers at NGI Technology Inc. (Billerica, MA) have combined the Texas Instruments (TI; Dallas, TX) TMS320C80 preprocessor and off-the-shelf components to accomplish that task. The result--the CL/SCAN steel-inspection system--uses defect libraries generated from the production line, hierarchical processing schemes, and rugged commercial products to operate as a host-based vision inspection system at the Nucor Corp. steel-processing plant in Berkeley, SC (see Fig. 1).

Real-time inspection

Working with steel-plant-tool-manufacturer SMS Schloemann-Siemag Inc. (Pittsburgh, PA), NGI set out to build a real-time, host-based, vision inspection system capable of detecting surface defects on steel sheets as they rolled along at high speeds in the factory`s "pickling" line. In the steel industry, pickling is a process that removes defects from the steel`s surface prior to other value-added pro cesses, such as galvanizing.

According to NGI`s director of sales and marketing James O`Hanley, the system`s operational success relies mainly on the defect image libraries that have been accumulated for a specific production line. These libraries markedly increase the CL/SCAN system`s ability to identify various defects. Although pickling is just one portion of steel-roll manufacturing, the CL/SCAN system can operate as efficiently at the galvanizing station or at any other point along the manufacturing line by merely changing the defect libraries.

The vision-inspection system starts with image acquisition by two digital-output, 2048-pixel, CL-C3-2048N linear arrays from Dalsa Inc. (Waterloo, Ontario Canada). These cameras are positioned to catch reflected light generated by a customized tungsten-halogen-powered fiberoptic lighting subsystem from Stocker & Yale Inc. (Salem, NH; see Fig. 2). A 14-element Model 1412 optical lens system from Nikon Inc. (Melville, NY) helps to obtain a nearly distortionless 90° field of view. The rolling steel sheets vary in size up to 80 in. wide. As a result, the total of 4096 active pixels provides 0.5-mm resolution.

According to NGI`s director of software engineering John Considine, the vision inspection system uses differential data transmission over twisted-pair wires to deliver digital imaging data to a Shearwater (Littleton, MA) C80 PCI preprocessing board that contains 40 Mbytes of on-board memory. Differential transmission is a commonly used technique to filter out signal noise. The heavy factory machinery in use on the production floor generates large amounts of electrical noise coupled into the digital data lines used to connect the cameras to the acquisition system.

The cameras must be centered over the steel line and their data have to be transmitted over distances of 10 to 30 ft to the image-acquisition cards. This distance, combined with the high-noise environment, makes differential data transmission the only viable option for delivering "clean data." By sending the data across the two communication wires with deflecting signals, noise, which appears as spikes in the same direction on both wires, can be filtered out, resulting in high-noise immunity. Twisting the shielded wires together ensures that they absorb the same noise signals.

Multiple processors

NGI chose the TI C80 preprocessor because of the engineering team`s familiarity with the design of this chip. This preprocessor contains five independent processors and a direct-memory-access (DMA) engine that are capable of performing 2 billion operations per second. The flexible DMA engine can move odd-shaped groups of data directly from the acquisition board`s first-in, first-out buffers directly to internal memory. A RISC processor with floating-point capability handles external interrupts, timing functions, and interprocessor communications and oversees the work of the DMA engine and the four digital-signal processors (DSPs). Each DSP is an identical very-large-instruction-word processor with parallel-processing capabilities that can be maximized with assembly software.

Says Considine, "The standard single instruction for each processor is 64 bits with extensions up to 96 bits. It can do more than 10 things at once, such as two loads, two stores, four adds, two multiplies, and logic operations; that`s how the processor gets its power. Each DSP does a lot in each clock cycle. The trick is to get all to come out at the right time." NGI has developed a compression algorithm that has the ability to compress image data by two to one for immediate storage.

Initially, NGI programmers had concerns about the speed of the bridge between the Shearwater PCI board (a recent acquisition from Ariel Corp., Cranbury, NJ) and the PCI internal bus. The Windows NT drivers for the board require the host to initiate the transfer, but this approach required the C80 to initiate the transfer to in crease processing speeds.

"The API [Application Programming Interface] from Ariel, which facilitated data transfers, was able to sustain only an 18-Mbyte/s read access and a 21-Mbyte/s write access. These speeds were insufficient for our needs and did not become apparent until we were well underway in code development," says Considine. He adds that NGI had researched other cards that offered up to a 80-Mbyte/s sustained transfer, but the cards` software was packaged so tightly with the product that switching would have caused additional system-integration problems.

The answer was to modify the device drivers so that the C80 could effectively initiate transfers and then use DMA for direct input into the final buffers, skipping the intermediate copy step. "We also increased the size of the maximum transfer to allow larger bursts of data to be transferred. The full set of modifications resulted in maximum sustainable transfer rates of 27 Mbytes/s of read and 48 Mbytes/s of write. At these levels, the C80 could move enough data to work as designed in the system," notes Considine.

Another problem with the PCI card concerned the on-board memory interface. Comments Considine, "When we first selected this board, it seemed to have all the things we were looking for: a digital camera interface, SDRAM, and 50-MHz operations. In fact, at the time, it was the only C80 card that had the kind of digital interface we needed for the cameras we wanted to use. Because of this, we were willing to accept the current cards that were using DRAM instead of SDRAM," says Considine.

This was an important design distinction because the DRAM-based cards could only operate at a two-cycle-per-column access for 40-MHz operation or a three-cycle-per-column access at 50 MHz. It also confronted the designers with a choice of having the processor run slower, but with higher memory bandwidth, or having a faster processing speed with lower memory bandwidth. Because the C80 provides a 64-bit data bus, the 40-MHz card can transfer data to or from memory at a maximum of 160 Mbytes/s, whereas the 50-MHz card can transfer data at rates to 136 Mbytes/s.

"To make a choice between the operating speeds, the designers had to determine whether the C80 was bound by processor utilization or memory bandwidth. In our case, we needed the extra memory bandwidth, so we went with 40-MHz operations," says Considine.

When Shearwater took over the card design, it asked NGI to work with it in testing and verifying the SDRAM modification. "Our systems now have the 50-MHz SDRAM design running on them. This is a big improvement for the system, because the processor is running faster with a peak memory bandwidth of 400 Mbytes/s," comments Considine.

Starts with detection

Using the preprocessor board, the CL/SCAN system starts a hierarchical detection process, beginning with the largest number of pixels and the simplest convolutions, and progresses to the smallest amount of image data and expert-level operations. The preprocessor accepts lines of image data, counts the lines, and synchronizes the frames with production-line speed and status data delivered by a separate 66-MHz, 486-type, single-board computer from Comark (Medfield, MA).

This computer board is used as the physical plant interface (PPI) card, which collects line-speed data and connects to the other process-line computers. This operation retrieves steel-sheet roll start/stop signals and roll-identification information so that the final defect report can be associated with the coils used on the line. The PPI board is attached to the system`s Comark backplane and into the Pentium II (Comark) host board`s ISA bus, which communicates with the PCI preprocessor through the host (see Fig. 3). An Ethernet card is hooked into the ISA bus for the remote retrieval of report data.

Considine says, "Comark designed our environmental enclosure for the processors, built our large PCI backplane, and supplied our single-board Pentium host and the 486-type single-board computer to ensure success in the harsh environment of the factory floor.

The preprocessor takes in the line data and determines the initial areas of interest based on intensity and spatial characteristics. Areas containing po tential defects are analyzed and reduced to statistical data sets that are passed on to the postprocessing board, a 233-MHz AD66-PCI Alpha single-board computer from Alpha Data Parallel Systems Ltd. (Edinburgh, Scotland). "We were looking for a fast processor with high-performance operation that we could develop in C language," explains Considine.

One reason that NGI decided to go with standard processors was to take advantage of rapidly evolving technology. This is demonstrated by Alpha Data`s 566-MHz processor, which is code compatible with the 233-MHz board. "If we need extra power in the postprocessor, we can just buy the 566-MHz board, plug it in, and run faster," says Considine. The new processor is used in place of adding a second Alpha computer board to the system for dark-field processing or can be used if additional requirements are added to the postprocessor.

The postprocessor board combines the one-dimensional defects into two-dimensional defects and applies a proprietary algorithm to pull areas of potential defects from the overall image. "Many traditional methods rely on a thresholding environment. We`ve developed something that`s more sensitive and able to pick things out of the background based on intensity and spatial characteristics in a quick and thorough manner," says Considine.

Because the Alpha board can operate as a full PCI bridge by itself, it can pass along 2:1 compressed images of the entire steel roll directly from the preprocessor to a FibreXpress Board from Systran Corp. (Dayton, OH). Although it`s a fiberoptic-based card, it can also accommodate a copper interconnect, which provides adequate bandwidth for this application, according to Considine. "If you want to run the data over long distances, you need to use fiber. But because we were plugging right into our system, the copper interface is a lot cheaper and easier to set up," he adds.

The data are stored in a Concert C814 FCS RAID Box from Storage Concepts (Irvine, CA). This storage system is generally used only during defect-library development and acceptance testing, when end users want to see why a run was rejected without having to unroll the steel), which could induce more surface defects (see Fig. 4). NGI is currently designing a new RAID option that will use an additional processor to store as much as six months of accumulated defect images. Based on end-user requests, this system should allow steel-mill operators to determine why certain faults are repeated.

The Alpha computer board also presented some challenges to the NGI design team. The board`s inherent communication suite, while satisfactory for the development process, became a processing roadblock during the embedding process. The answer was to run the system in stand-alone mode, delete the standard input/output routines, and build a new communications library from scratch. During system integration, the board lacked the ability to run in master mode; it depended on the host to initiate transfers, which limited the benefits of using the board`s internal PCI bus.

According to Considine, the new communications library is 95% common to all the processors in the system. The remaining 5% of the routines are low-level functions, which are written specifically for each processor and relate to reading and writing physical memory and signaling protocols. The new communications library allows the 486 processor to interface with the preprocessing board and the C80 to communicate with the Alpha board, each of which is from a different manufacturer.

During system operation, the Alpha board builds the two-dimensional defects from the one-dimensional line data and continues the image-data-filtering process; the digital defect data pass on to the 166-MHz Pentium II host for conversion into a waveform before being delivered to a primary classifier. This classifier, an Olson Reticular Brain Stem Processor that is a fuzzy-data-set board from BrainTech (North Vancouver, BC, Canada), also connects to the PCI bus and determines the most likely match between a given defect and a stored library of known defects produced by a particular rolled-steel production line. The answer is given as a best-percentage match and is attached to the image data for return to the host processor.

"We selected this processor because it provided a fast comparison mechanism to classify our defects. In the past, we used several variations of a Minimum Absolute Difference classifier, but it used a large amount of processing power and required the manual weighting of those characteristics that differentiate the defects. This was a time-consuming process, and the code had to be changed with each new production-line type. With the BrainTech classifier, we are able to use real defects to train the system, and the library building software automatically determines the weighting of the various defect parameters," says Considine.

At this point, an expert software program running on the host performs the final analysis. The text-based software system accepts the two-dimensional defect image data with the primary classification (for example, a long dark line stretching from a,b to x,y or a circle with radius x) and determines a final classification based on the proximity between different defects and the location on the roll, among others. For instance, a pair of lines that are less than a certain distance from each other are identified as a single crack, whereas a defect that lies close to the end of the roll or on the side might be in an area that is outside the steel mill`s requirements, and is therefore not relevant. Another clear delineator between primary and secondary classification data is that primary data would not make sense to an end user, but a secondary textural classification would.

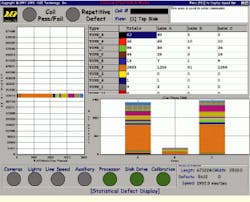

The secondary classifier also determines whether or not a given roll of steel meets a certain grade based on parameters set by the steel industry, the manufacturer, and the end user. Final roll data can be displayed on a monitor with a graphical user interface and stored on the system`s 4-Gbyte hard drive, which can be accessed by remote offices via a local-area network (see Fig. 5).

Despite the number of different manufacturers, boards, and processing steps, Considine estimates that the real-time CL/SCAN system sustains somewhat less than half of the PCI bus peak performance (130 MHz), which allows room for double-side inspection or dark-field analysis. NGI expects to expand beyond pickling lines to cover virtually every step in the steel-production process. Analysts project that in the United States more than 200 steel lines could use multiple vision-inspection systems.

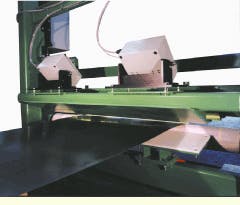

FIGURE 1.The CL/SCAN rolled-steel vision-inspection system can be built into existing steel-processing lines by interfacing an operator`s console, mounting structure, electrical junction boxes, and retractable roller. End users can also install the vision system separately or adapt it to a steel-roller already on their line.

FIGURE 2.The CL/SCAN vision inspection system comes with two linear-array cameras to obtain proper resolution; however, additional pairs of cameras can be added for dark-field analysis or underside processing or both. Transparent guards protect the illumination lights and the optics interfaces from flying pieces of steel or other contaminates.

FIGURE 3.The Comark NEMA-4-rated operator`s console can withstand the harsh steel-mill environment.

FIGURE 4.RAID storage box attached to the vision inspection system during acceptance testing stores the imaging data obtained from the steel-roll production line. Plant operators can see the actual location of defects after inspection to verify that the vision system is working properly. In the future, a less-expensive version of the RAID box will store only the image data that relates to the defect areas.

FIGURE 5.Final defect data can be displayed on a graphical user interface for showing the types of defects, their locations on the steel roll, and the grade of steel based upon the cumulative defects and parameters set by the end user.