Vision and analog boards inspect timer modules

Many houses are equipped with embedded electronic timer modules to control the operational sequences of electrical equipment such as water heaters and lighting units. Most timer modules are programmable, which allows several different events to be sequentially initiated and key parameters to be shown on a built-in liquid-crystal display. To ensure proper operation after manufacture, all programmable functions of the timer modules must be tested before shipment. Because the test process can involve checking a number of different pushbutton sequences, manual inspection is repetitive, time-consuming, expensive, and tiresome.

To eliminate manual checking of these parts, manufacturers of timer modules, such as General Electric (Graesslin, Germany), are turning to specialists in testing electronic modules, such as Konrad Technologie (Radolfzell, Germany), to develop custom test and handling systems. Konrad also develops system components for electronic measurement applications when no standard products are available.

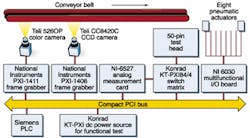

To create the automated test station for timer modules, Markus Jegler, a software developer at Konrad, coupled a number of off-the-shelf vision components with readily available analog I/O boards. In the final test system, electronic timers are placed in fixtures on a conveyor belt where they pass under a two-stage inspection station. In the first stage, the vision system checks the surface-mounted components for placement accuracy. To accomplish this inspection, a 5260P CCD camera from Tokyo Electronic Industry Company Ltd. (TELI; Tokyo, Japan) captures images of the timer modules. These images are then digitized by a PXI-1411 CompactPCI-based frame grabber from National Instruments (NI; Austin, TX).

"To inspect whether all the components are present and properly mounted," says Jegler, "pattern-matching routines within National Instrument's IMAQ-Vision software were used." After all the parts are confirmed for placement, the vision system triggers a programmable logic controller (PLC) to move the timer module to the next inspection stage. In the second stage, another TELI CS8420C camera digitizes the timer module images using the NI PXI-1408 frame grabber.

Next, the timer module is tested for proper timing function operations when the device is activated in a specific manner. "To activate the large number of routines on the timer," says Jegler, "it was necessary to probe approximately 50 points on the device." This probing was accomplished by coupling a 50-needle-probe test stage with a CompactPCI KT-PXI 84/4 switch matrix board from Konrad and an NI 6527 CompactPCI analog measurement board with parallel, isolated, 48-bit digital I/O interfaces.

After the test sequences are determined, they are programmed to actuate eight pneumatic cylinders using an NI 6030 multifunction I/O board. When a specific sequence is actuated, the analog measurement board tests the voltage levels at specific points on the device. At the same time, images of the timer display are digitized by the PXI-1408 frame grabber. Using pattern-recognition algorithms of the IMAQ software, the digitized images are examined to check whether they show the correct pattern. After voltage levels and images have been checked for each timer sequence, the PC activates the PLC over an RS-232 interface to move the next module into the inspection station.